A split shaft device for bonding bamboo and wood straw processing

A technology of bamboo, wood and straws, which is applied in wood processing equipment, sugarcane machining, manufacturing tools, etc., and can solve the problems of reduced production efficiency, product scrapping, and high breakage rate of drill bits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

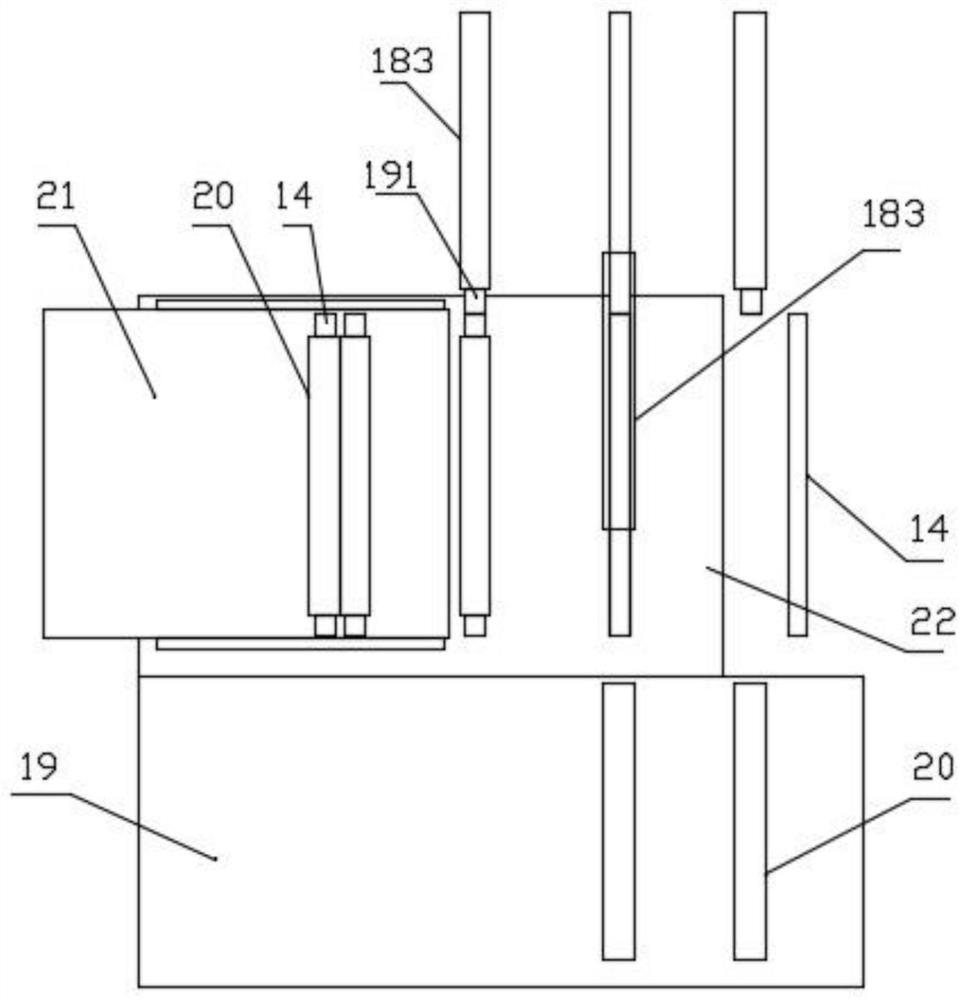

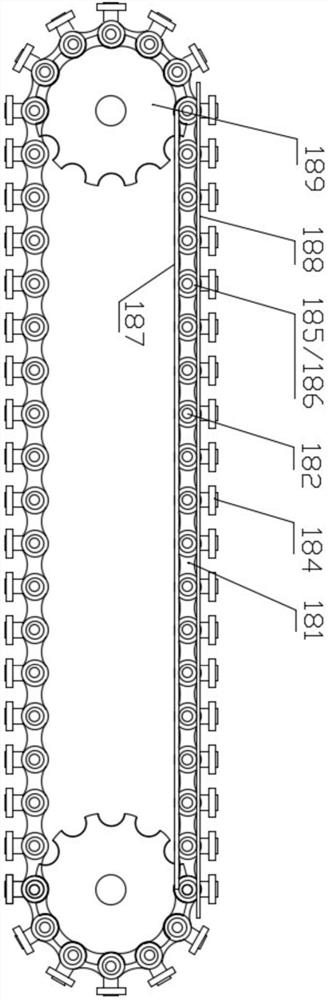

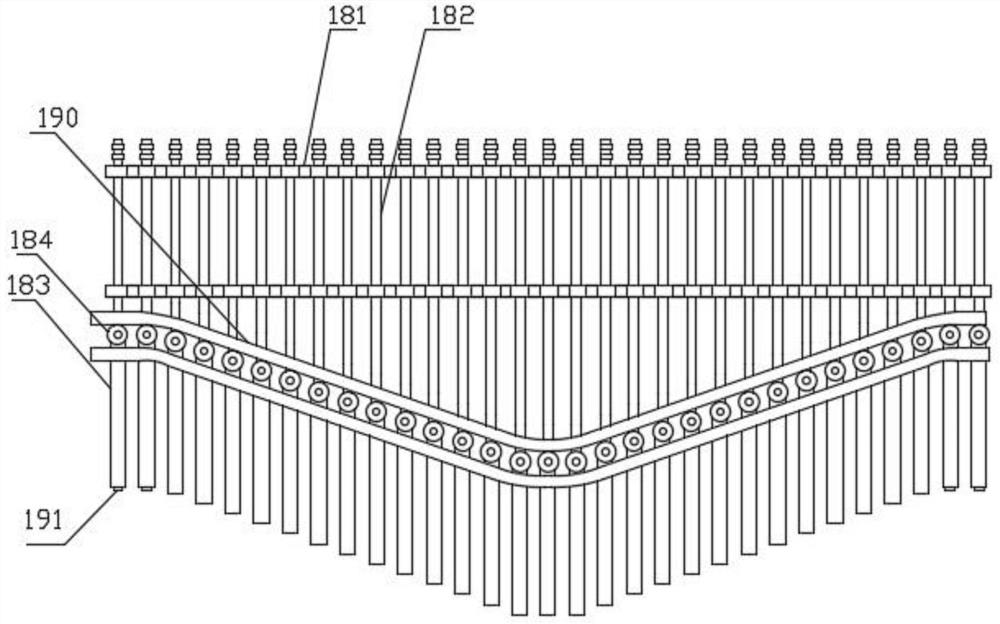

[0028] Such as Figure 1-6 As shown, a kind of split shaft device for bonding bamboo and wood straw processing, it is arranged on the discharge end of feeding conveyor belt 21, and it includes two synchronously moving chains 181; A central shaft 182 is arranged between them; the front end of the central shaft 182 extends from the end face of the chain 181 and is provided with an electromagnet 191, and the tail end extends from the end face of the chain 181 and is provided with a negative pole ring 186 and a positive pole ring 185; the positive pole The ring 185 is in contact with the positive rail 187...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com