Color master batch for improving light transmittance display, preparation method and application

A technology of color masterbatch and titanium dioxide, applied in the field of functional masterbatch, can solve the problems of increasing the brightness of the display panel, enlarged and blurred LED lamp fonts or patterns, etc., and achieves the effect of improving production efficiency, simple preparation method and increasing brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0082] The preparation method of the above-mentioned color masterbatch for improving light transmission and display includes the following steps:

[0083] Step 1: Take each raw material according to weight percentage, add filler, auxiliary agent and carrier resin into the mixer and mix to obtain the mixed material;

[0084] Step 2: Add the mixed material prepared in step 1 into a twin-screw extruder, extrude and cut into pellets to make masterbatch.

[0085] In one embodiment, the mixer is a high speed mixer.

[0086] In one embodiment, the mixing time is 10-30 minutes.

[0087] In one embodiment, the mixing time is 20 minutes.

[0088] In one embodiment, the temperature of the twin-screw extruder is set at 190-230°C.

[0089] In one embodiment, the temperature of the twin-screw extruder is set at 200-220°C.

[0090] In one embodiment, the temperature of the twin-screw extruder is set as Zone 1: 205°C, Zone 2: 210°C, Zone 3: 215°C, and the head temperature is 210°C.

[00...

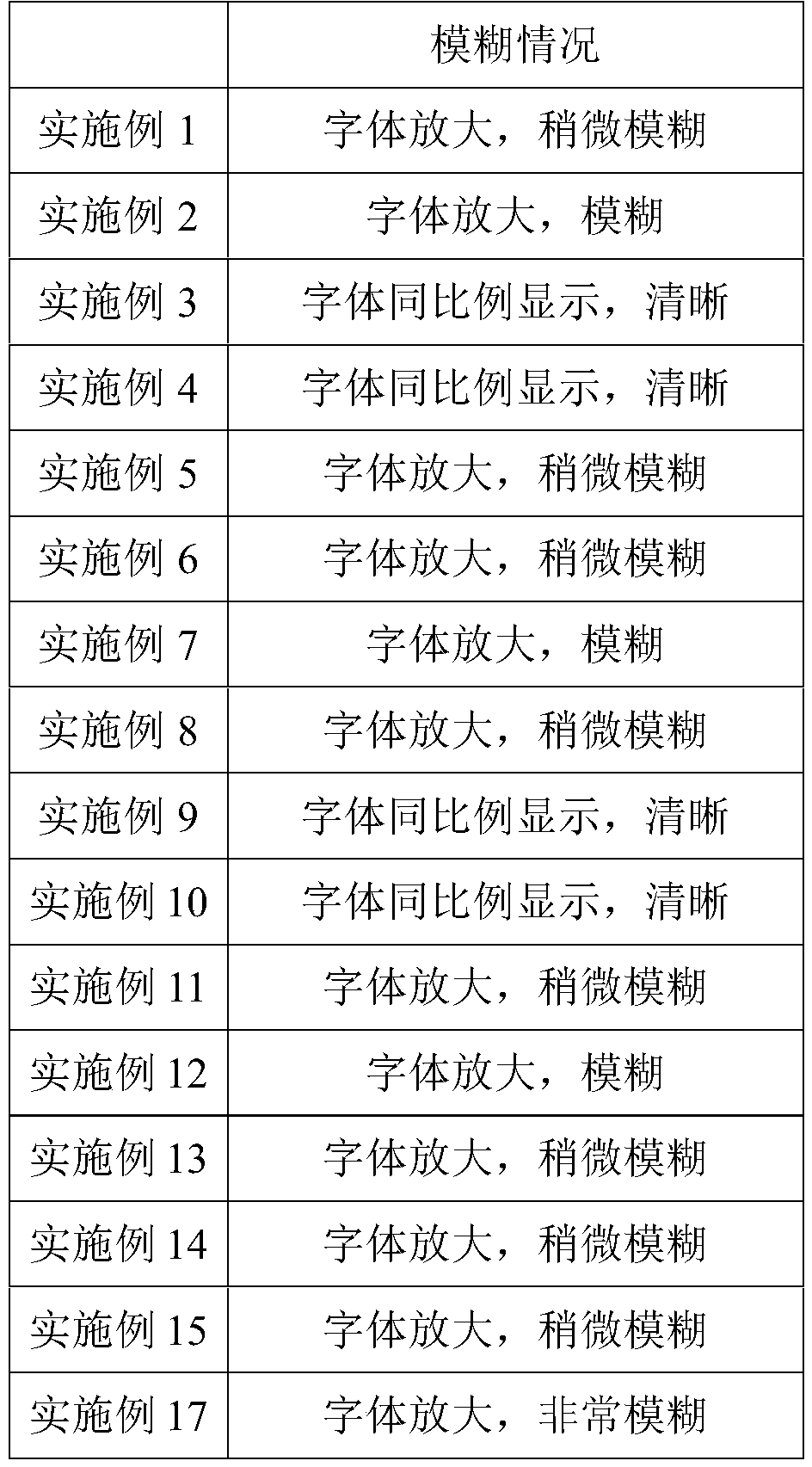

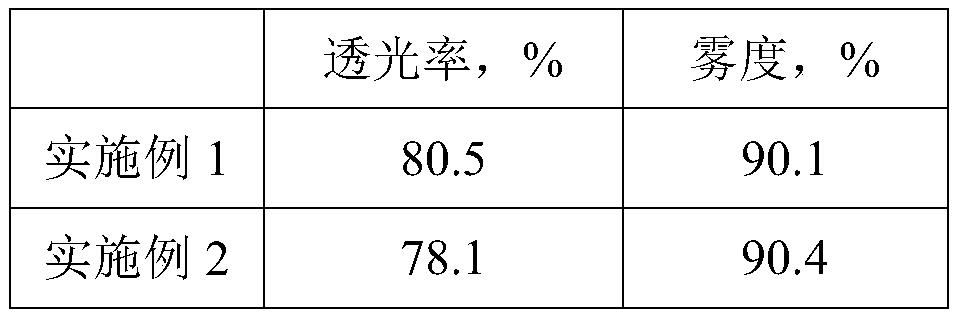

Embodiment 1

[0103] The color masterbatch for improving light transmission and display is prepared from the following raw materials in weight percentage: 35% filler, 13.62% additive, and 51.38% carrier resin.

[0104] The filler is titanium dioxide.

[0105] The average particle size of the titanium dioxide is 0.25 μm; provided by Jiangxi Tianguang Titanium Industry Co., Ltd., the crystal form is rutile, and the model is TR-33.

[0106] The carrier resin is formed by mixing HIPS and PS, and the weight ratio of HIPS and PS is 1:1.1.

[0107] The melt flow index of the HIPS is 9.5g / 10min, and the glossiness is 70GU at 60°; specifically, the HIPS with the brand name HPS-800F provided by Gaofu Chemical Industry Co., Ltd. is used.

[0108] The melt flow index of the PS is 20g / 10min; specifically, the GPPS with the brand name GPS-525HF provided by Gaofu Chemical Industry Co., Ltd. is used.

[0109] The auxiliary agent includes 0.12 parts of colorant, 4 parts of EBS, 4 parts of PETS, 1.5 parts ...

Embodiment 2

[0117] The color masterbatch for improving light transmission and display is prepared from the following raw materials in weight percentage: 35% filler, 13.62% additive, and 51.38% carrier resin.

[0118] The filler is zinc sulfide.

[0119] The zinc sulfide is nano zinc sulfide with a particle size of 50nm; provided by Shanghai Buhan Chemical Technology Co., Ltd.

[0120] The carrier resin is formed by mixing HIPS and PS, and the weight ratio of HIPS and PS is 1:1.1.

[0121] The melt flow index of the HIPS is 9.5g / 10min, and the glossiness is 70GU at 60°; specifically, the HIPS with the brand name HPS-800F provided by Gaofu Chemical Industry Co., Ltd. is used.

[0122] The melt flow index of the PS is 20g / 10min; specifically, the GPPS with the brand name GPS-525HF provided by Gaofu Chemical Industry Co., Ltd. is used.

[0123] The auxiliary agent includes 0.12 parts of colorant, 4 parts of EBS, 4 parts of PETS, 1.5 parts of antioxidant, 2.5 parts of light stabilizer and 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com