Self-resetting fully prefabricated bridge pier-cap structure and its assembly method for easy post-earthquake repair

A prefabricated cap, self-reset technology, applied in the erection/assembly of bridges, bridges, bridge construction, etc., can solve the problem of hindering the research and application of the fully prefabricated pier-cap structure, and the long-term use performance of repairability needs to be further resolved. , ground contact surface damage and other problems, to simplify daily maintenance work, reduce grouting difficulty, and reduce life cycle costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

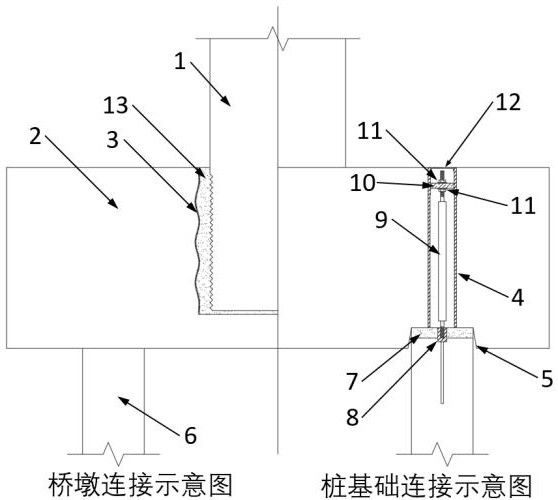

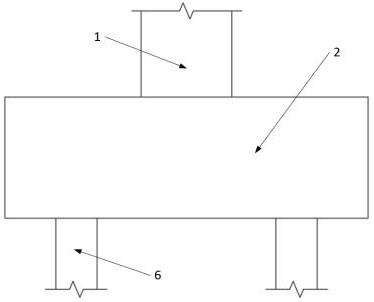

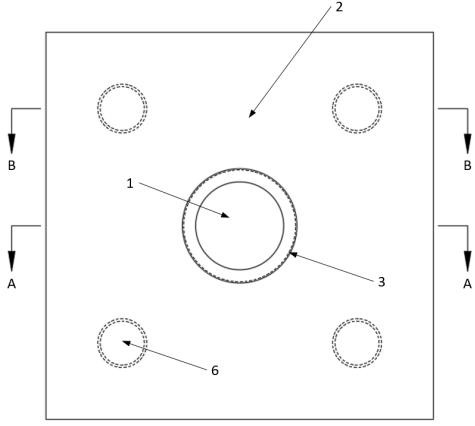

[0035] A self-resetting fully prefabricated pier-cap structure that is easy to repair after an earthquake, including prefabricated pier 1, prefabricated cap 2 and pile foundation 6, such as figure 2 As shown, the pile foundation 6 is located under the prefabricated cap 2, bearing the weight of the prefabricated cap 2 and the prefabricated pier 1 and the dynamic and static load of the bridge; Steel pipes with internal and external threads are made into reserved channels 4, such as figure 1 shown; figure 1 It is the overall view of the pier-cap structure of the present invention. The prefabricated pier 1 is inserted into the reserved opening 3 and connected with the prefabricated cap 2. The connection between the prefabricated pier and the prefabricated cap can refer to the attached image 3 , the top view of the structure of the present invention and the attached Figure 5 ;

[0036] Also includes energy dissipation ribs 9, the energy dissipation ribs 9 are located in the res...

Embodiment 2

[0040] An assembly method for a self-resetting fully prefabricated pier-cap structure that is easy to repair after an earthquake includes the following steps:

[0041] Preparation steps: When prefabricating the cap, the reserved openings on the top of the cap and the reserved channels of the cap should be arranged in strict accordance with the design plan, and their positions should be confirmed after review. The reserved channel should be made of steel pipe with internal and external threads, the external thread ensures the anchorage between the steel pipe and the cap concrete, and the internal thread is used to connect energy-dissipating tendons. Measure the pile position and ground elevation to ensure that the deviation of the pile center position is within the allowable range. After the poured concrete is solidified, remove the pile head mud and the concrete 0.5 meters below the pile top elevation.

[0042] S1. After cleaning the surface of the pile head, pour concrete an...

Embodiment 3

[0050] The method of using the self-resetting fully prefabricated pier-cap structure that is easy to repair after the earthquake, when the prefabricated cap undergoes rotational displacement under the action of the earthquake:

[0051] Step 1: Open the protective cover of the reserved hole, remove the fixing nut and the threaded insert in the center hole, and unscrew the energy dissipation tendon from the bottom threaded anchor;

[0052] Step 2: Screw the new energy-dissipating tendon into the threaded anchorage at the top of the pile foundation, install the central hole threaded insert and fixing nut, complete the connection between the top of the energy-dissipating tendon and the prefabricated cap, and then install the reserved hole protection cover, The bridge immediately regained its seismic performance.

[0053] The invention has no damage to other parts except the yielding of the energy-dissipating tendons under the action of the earthquake, thereby ensuring the use func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com