Reinforced concrete frame joint beam hogging moment assembled steel structure and reinforcing method thereof

A technology of reinforced concrete and frame beams, applied in building construction, building maintenance, construction, etc., can solve the problems of insufficient reliability, poor fire resistance of chemical materials, easy aging, etc., and improve the negative bending moment bearing capacity of nodes , Improve the efficiency of reinforcement construction, and the effect of less building space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

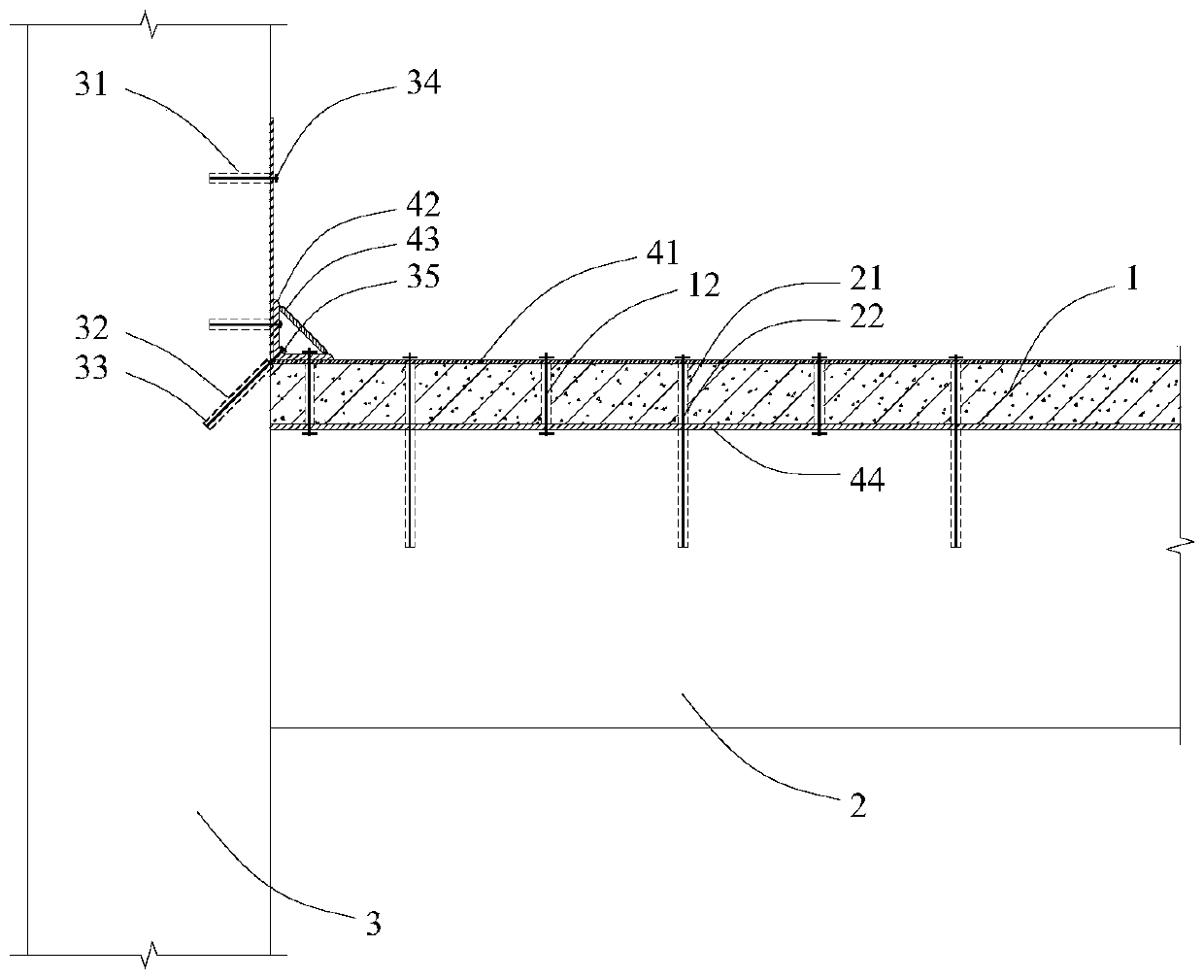

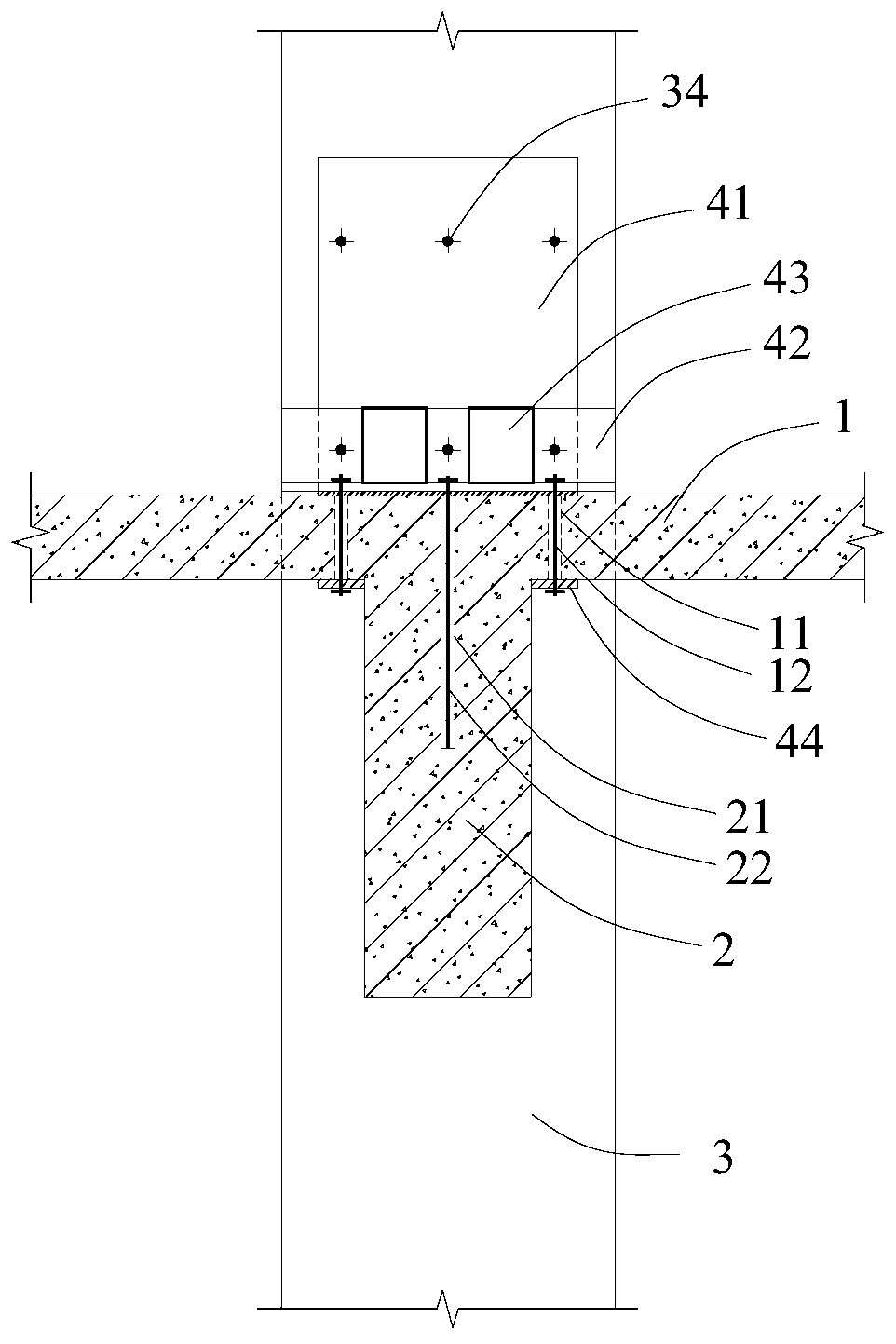

[0039] The present invention is a reinforced concrete frame node beam negative moment assembly steel structure, such as figure 1 and figure 2 As shown, it includes high-strength steel strip 41, angle steel 42 and longitudinal steel strip 44 at the bottom of the floor; the reinforced concrete frame node includes vertically arranged frame columns 3, vertical frame columns 3 horizontally arranged frame beams 2, and vertical frame The column 3 and the frame beam 2 are horizontally arranged on the floor 1 on the frame beam 2; the high-strength steel strip 41 is bent at right angles and fitted on the upper layer of the floor 1 and the frame column 3, and the high-strength steel strip 41 is respectively connected with the The floor 1 and the frame column 3 are fixed; the angle steel 42 is fixed at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com