A constant elastic coating involute spiral groove long-life sealing device

A technology of sealing device and spiral groove, which is applied in the direction of engine sealing, gas turbine device, jet propulsion device, etc., can solve the problems of end face wear, unreasonable spiral groove shape, and affecting sealing performance, etc., and achieve the best hydrodynamic pressure effect, Avoid the original equilibrium state and enhance the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

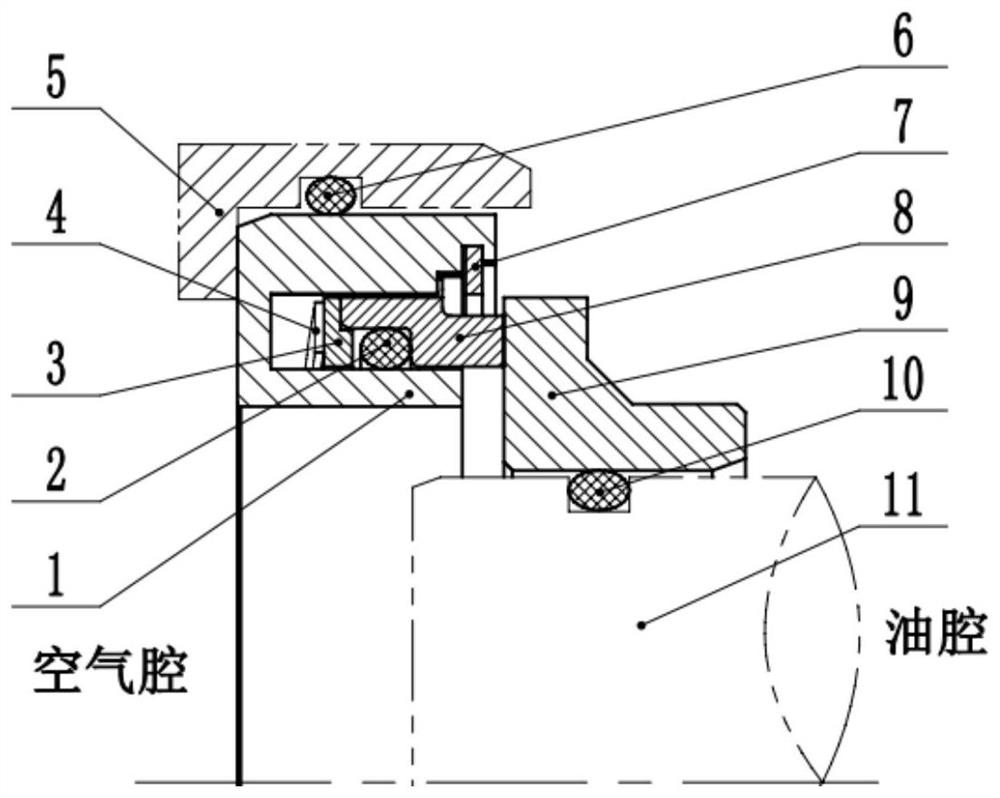

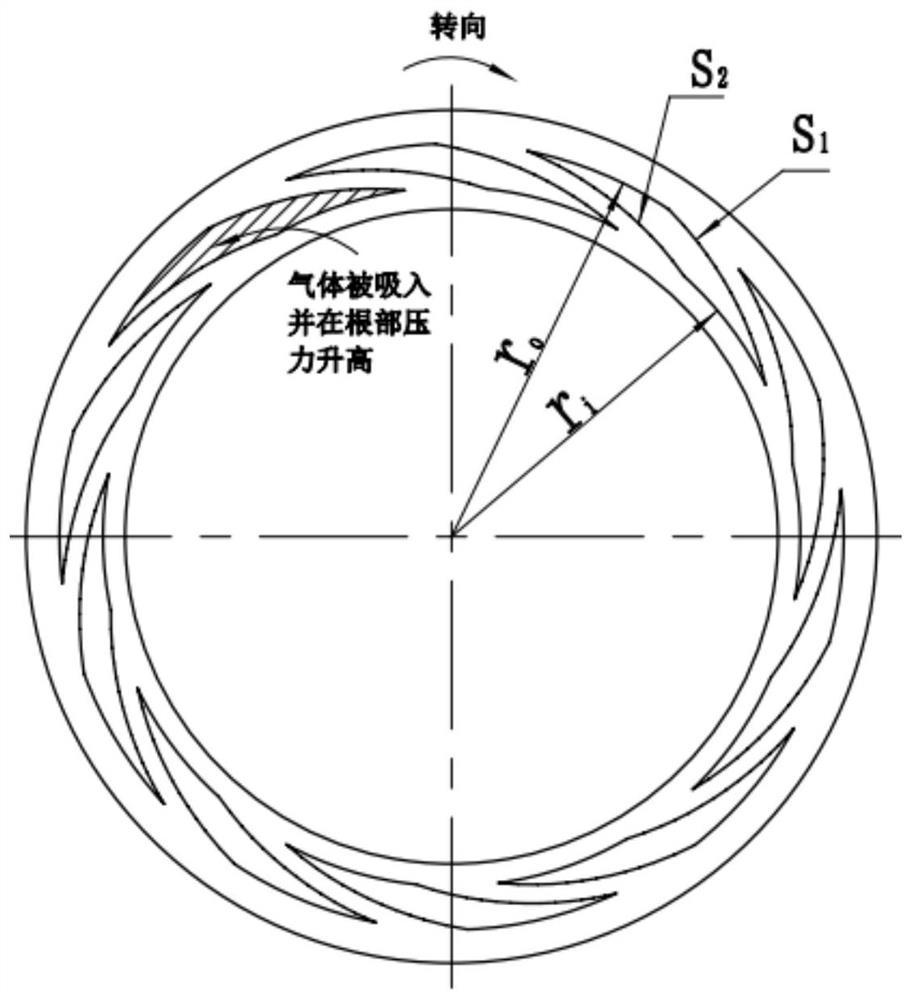

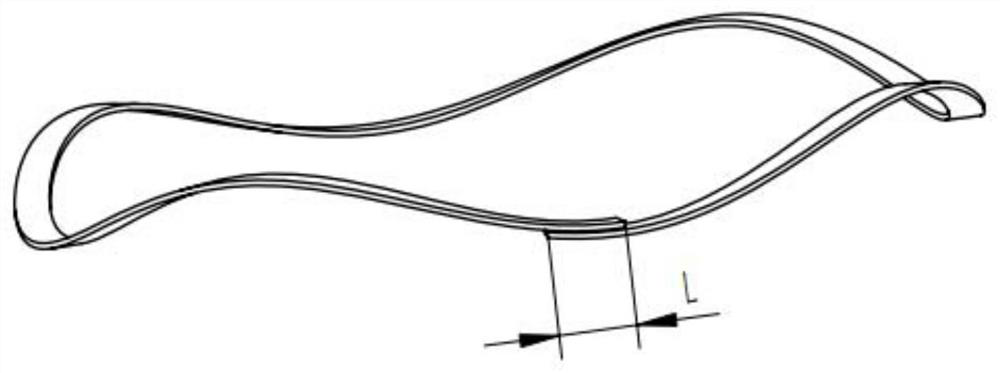

[0026] like figure 1 As shown, a constant elastic coating involute spiral groove long-life sealing device disclosed in this embodiment includes a sealing shell 1, a first sealing rubber ring 2, a pressure plate 3, a lap wave spring 4, and a second sealing rubber ring 6. Back-up ring 7, graphite ring 8, sealing dynamic ring 9 and third sealing rubber ring 10. The constant elastic coating involute spiral groove long-life sealing device is used to isolate the oil cavity from the air cavity, prevent the lubricating oil in the oil cavity from leaking into the air cavity, and achieve the purpose of sealing oil. The lap wave spring 4 is used to generate an axial force, which is transmitted to the graphite ring 8 through the pressing plate 3 to ensure that the graphite ring 8 is in close contact with the sealing dynamic ring 9 to form the main sealing surface; the sealing shell 1 and the machine The box housing 5 is sealed by the second sealing rubber ring 6, the graphite ring 8 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com