A high-efficiency garbage incinerator

A garbage incinerator, high-efficiency technology, applied in the direction of incinerators, combustion types, steam boilers, etc., can solve the problems of time-consuming and labor-intensive incineration, poor incineration treatment effect, and low incineration efficiency, so as to improve the effect, save manpower output, improve The effect of combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

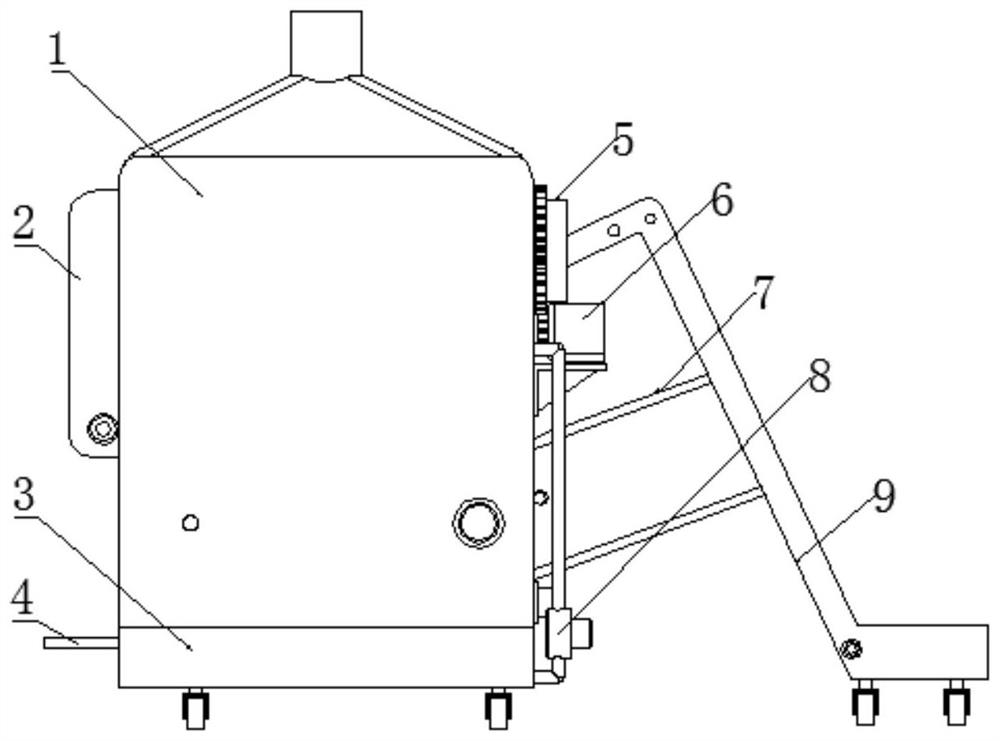

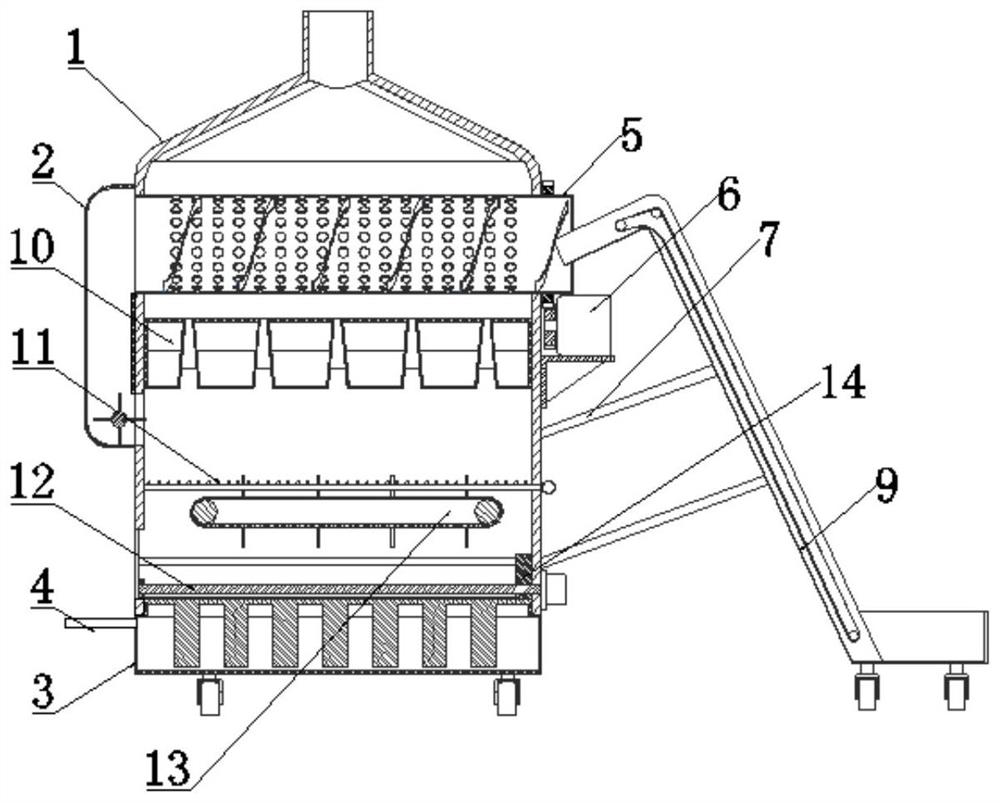

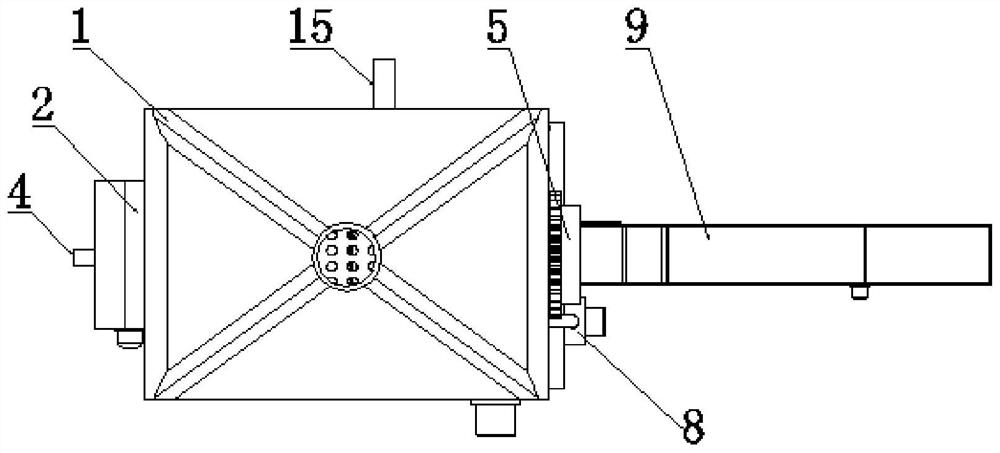

[0031] Example 1, please refer to figure 1 , figure 2 , image 3 , Figure 4 with Figure 10 , including a furnace body 1, a base 3 and a feeder 9, the lower end of the furnace body 1 is provided with a base 3, and the lower end surface of the base 3 is provided with rollers, the base 3 plays a supporting role for the furnace body 1, and the rollers provided improve the incineration. The use of the furnace is flexible. The inner side of the furnace body 1 near the upper end is horizontally installed with a drying cylinder 5. The drying cylinder 5 realizes the drying treatment of garbage, and the right end of the drying cylinder 5 is located outside the furnace body 1. A ring gear is sleeved , the drying cylinder 5 is meshed with a drying motor 6 through the ring gear, and the drying motor 6 is installed on the right end surface of the furnace body 1 through a fixed frame. The drying motor 6 drives the drying cylinder 5 to rotate through gear transmission to ensure uniform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com