Body-in-white welding spot optimization method based on variable density method and fatigue life analysis

A technology of fatigue life analysis and optimization method, applied in instruments, calculations, combustion engines, etc., can solve the problems of difficult solder joint layout, inaccurate fatigue life analysis, etc., to improve modal performance, reduce design variables, and reduce solder joints effect of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

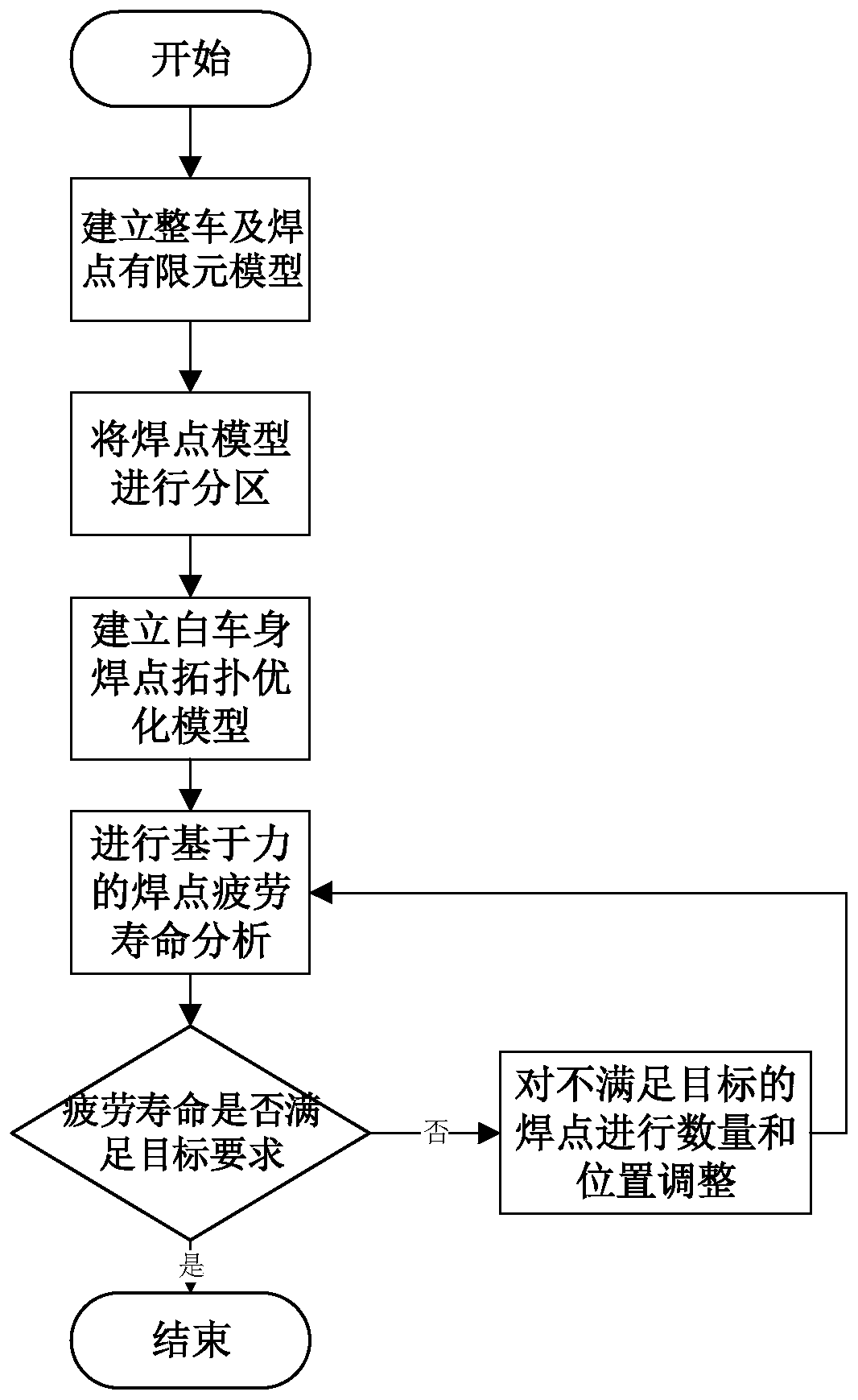

[0063] Such as figure 1 As shown, a method for optimizing solder joints of body-in-white based on variable density method and fatigue life analysis, the specific steps include:

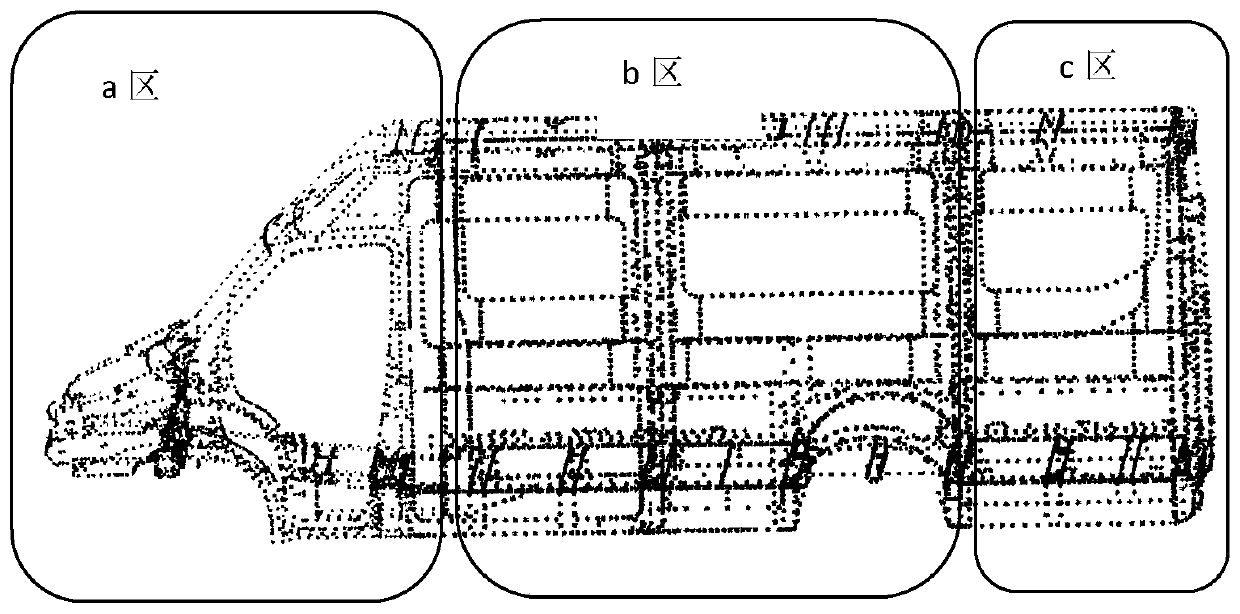

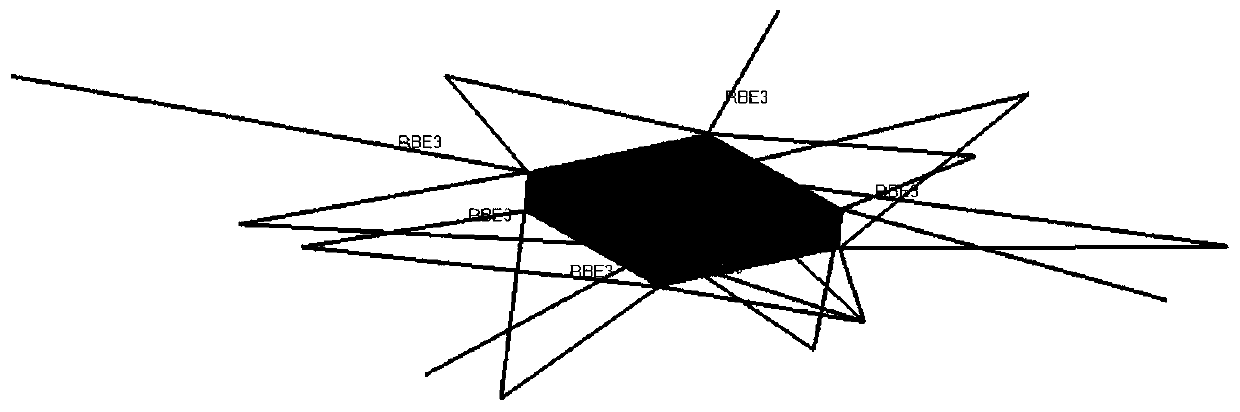

[0064] Step 1: Establish the finite element analysis model and the solder joint finite element analysis model according to the modeling standard according to the 3D model of a commercial vehicle. The solder joint establishment type adopts ACM, and its structure is as follows figure 2 shown. The ACM unit is composed of several groups of rbe3 units on the surface and a solid unit in the middle. Its structure is as follows image 3 shown. A total of 437189 grid cells were established. 97371 solder joints.

[0065] Step 2: Divide the established solder joints into zones according to the degree of influence on the performance of the first-order torsional mode of the body-in-white. Partition results such as figure 2 hint. The front solder joint with a large proportion of low-order vibration is reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com