Electric spindle pipeline layout system

An electric spindle and pipeline technology, which is applied in the directions of large fixed members, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of complex pipeline layout and design, and achieve high-speed rotation, reduce production costs, and be easy to manufacture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

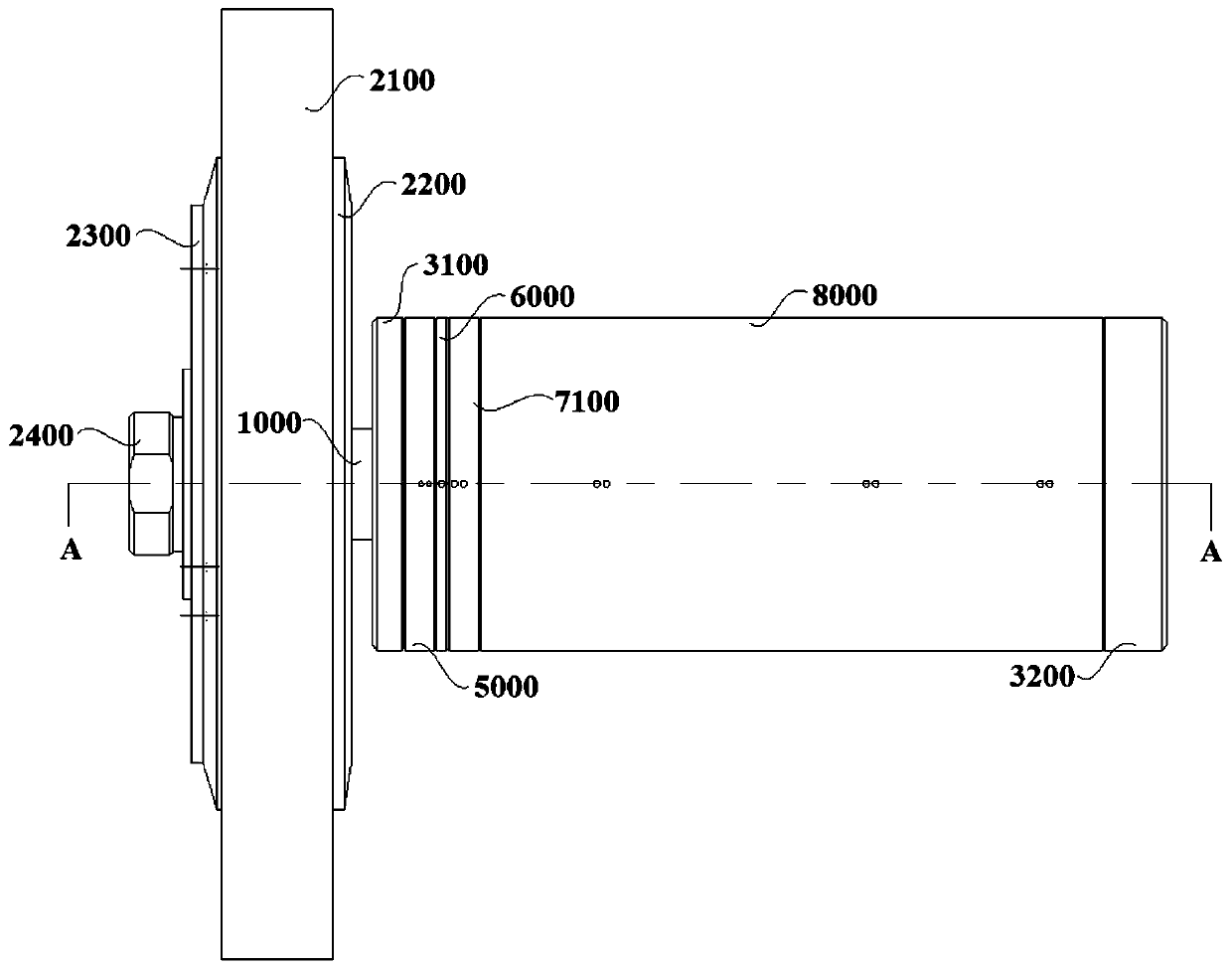

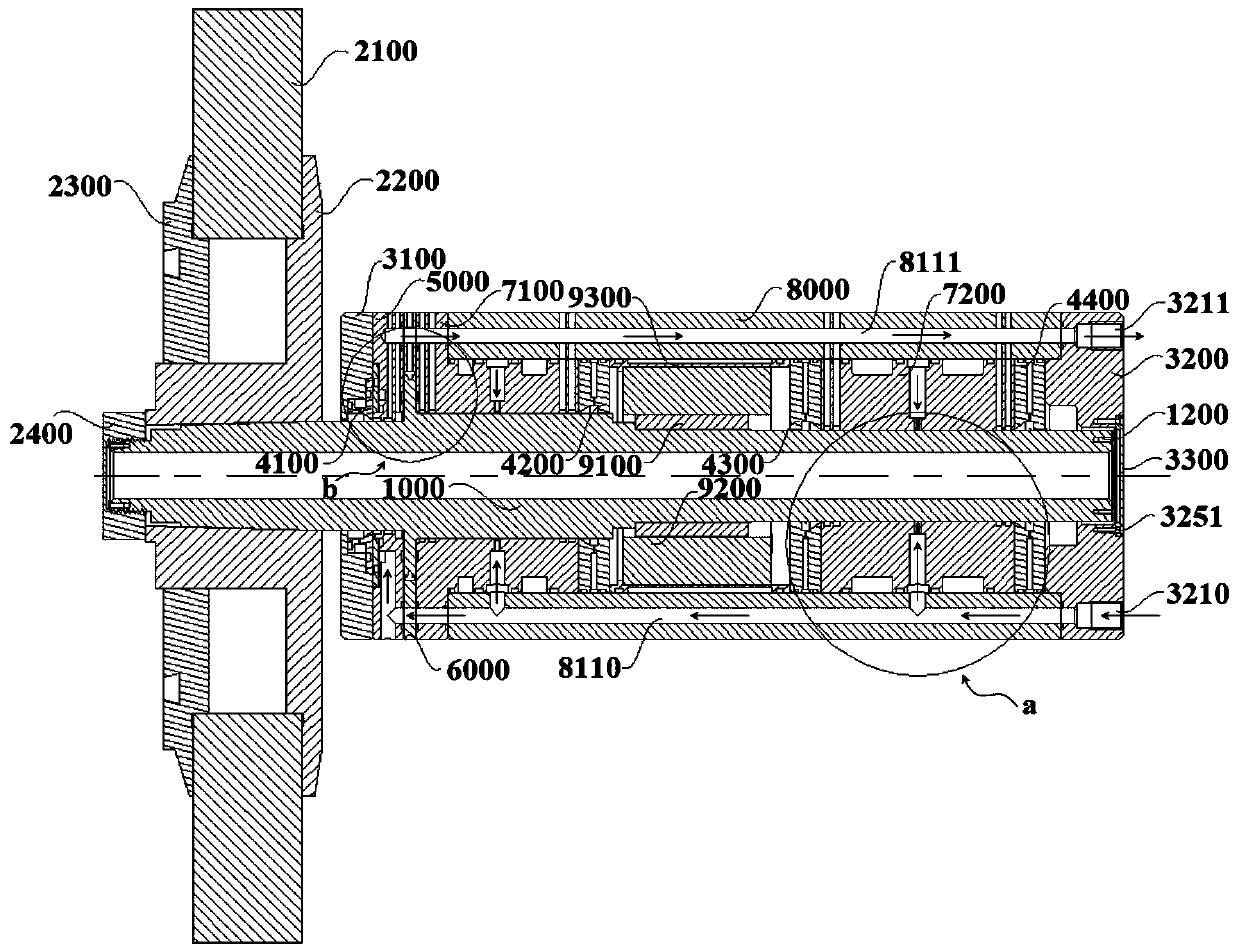

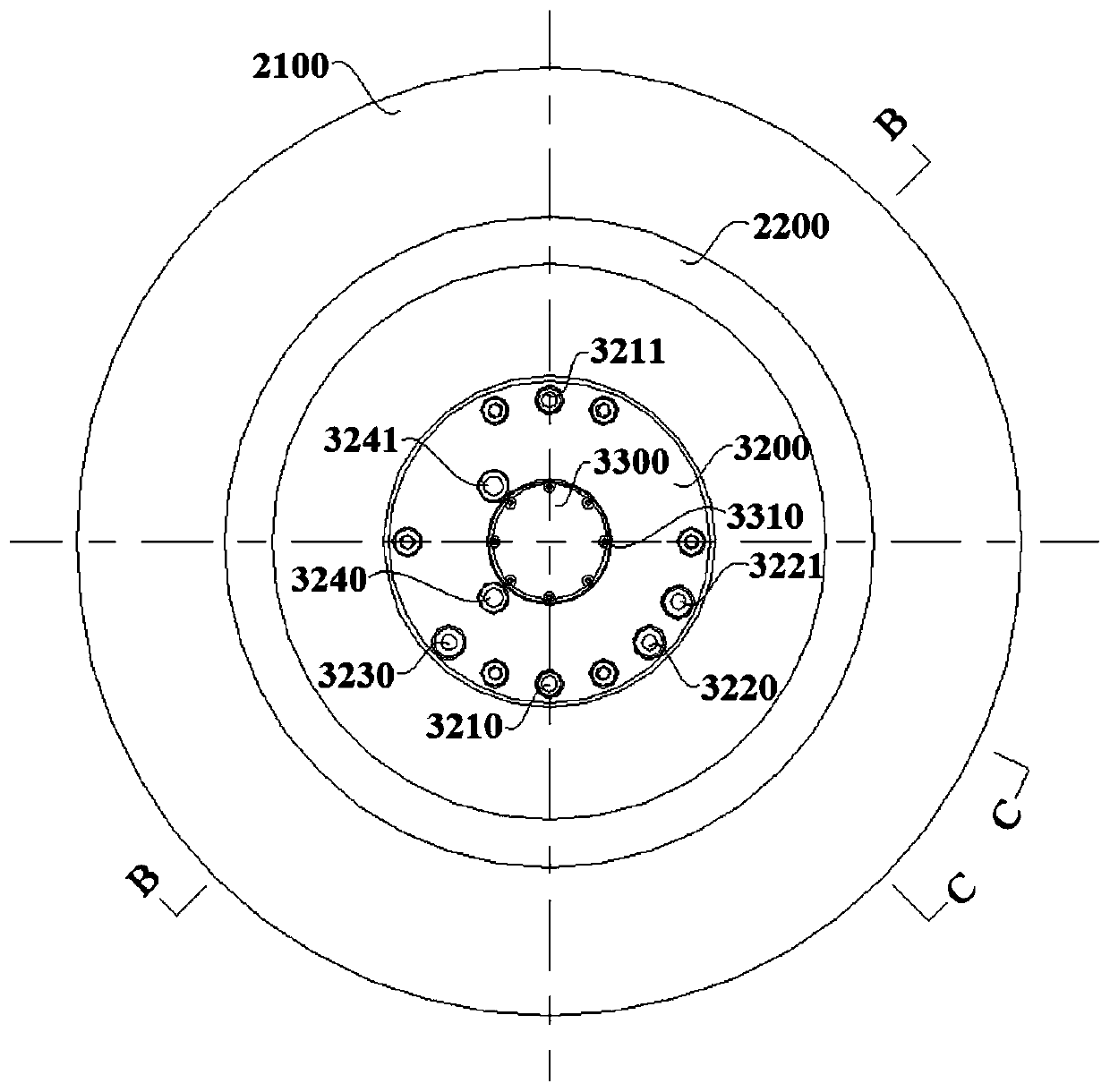

[0070] combine figure 1 , an electric spindle pipeline layout system in this embodiment includes a grinding wheel 2100 installed on the mandrel 1000 and a drive unit, wherein the grinding wheel 2100 is installed on the front end of the mandrel 1000, specifically, combined with figure 1 , figure 2 and Figure 8 , the grinding wheel 2100 is installed on the grinding wheel flange 2200, and the grinding wheel 2100 is fixed on the grinding wheel flange 2200 through the grinding wheel gland 2300; the front end of the mandrel 1000 passes through the grinding wheel flange 2200, and is connected with the The front end of the mandrel 1000 is threaded. The driving unit in this embodiment is arranged in the middle of the mandrel 1000, and is used to drive the mandrel 1000 to rotate, thereby driving the grinding wheel 2100 to rotate, and to grind the workpiece.

[0071] The driving unit in this embodiment includes a rotor 9100 and a stator 9200, such as figure 2 As shown, the rotor 9...

Embodiment 2

[0115] An electric spindle pipeline layout system in this embodiment is basically the same as in Embodiment 1, further: the inclined surface of the trapezoidal inner chamber on the sealing ring in this embodiment and the central axis of the respective corresponding sealing rings The included angle is 15°-75°.

[0116] In this embodiment, the included angle between the inclined surface and the central axis of each corresponding sealing ring may be 15°, 20°, 30°, 45°, 60° or 75°.

[0117] It is worth noting that the inclined surface plays a guiding role in the whole process, and also plays a role of pressurization, guiding the gas flowing into the inner cavity of the sealing ring to the annular groove. The smaller the angle between the axes, the greater the guiding effect of the inclined surface, which is more conducive to guiding the gas into the annular groove; but the smaller the angle between the inclined surface and the central axis of the sealing ring, the greater the dist...

Embodiment 3

[0120] An electric spindle pipeline layout system in this embodiment is basically the same as in Embodiment 2, further: in this embodiment, in order to cool the cooling water in the front annular water channel 7130, the rear annular water channel 7220 or the water cooling channel 9310 The effect is better, the front block 7140 in the front annular water channel 7130 forms a certain angle with the side of the front annular water channel 7130, and the angle is an acute angle, that is, the front block 7140 is arranged obliquely. At the same time, in this embodiment, the positions of the bearing water inlet branch pipes and the bearing water outlet branch pipes located on both sides of the front stopper 7140 are arranged, that is, the position where the bearing water inlet branch pipes communicate with the front annular water channel 7130 is located on one side of the front stopper 7140 Between the acute angle formed by one side of the front annular water channel 7130, the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com