On-line efficient glass fiber wire-drawing discharge spout processing cutting fluid powder extracting device

A glass fiber drawing and extraction device technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of wear, time required, and high material value of leak nozzle processing equipment, and achieve the effect of reducing unnecessary wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

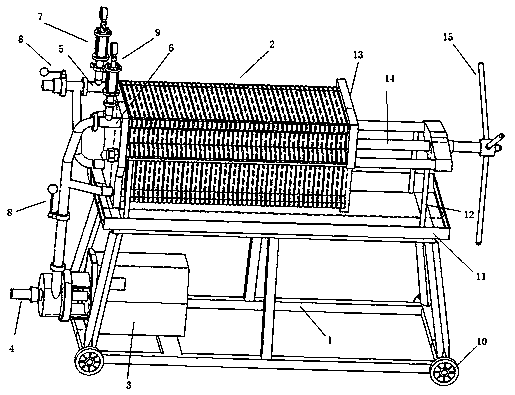

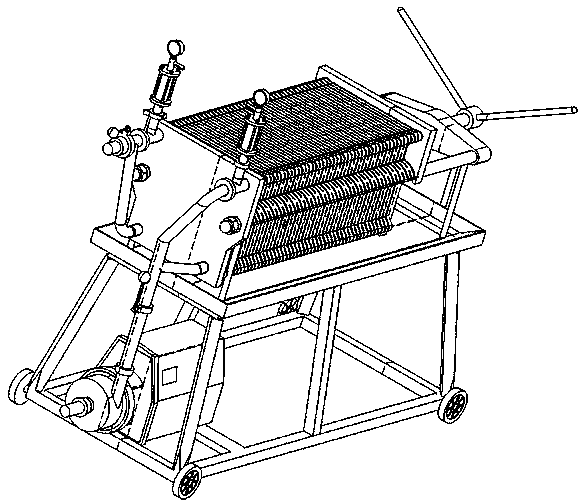

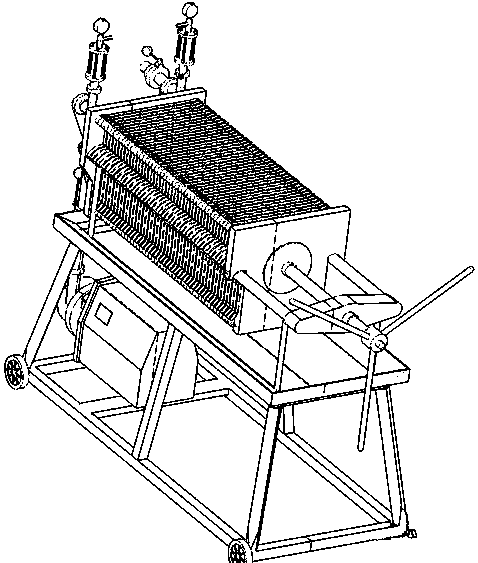

[0016] according to figure 1 , 2 As shown in . There are a paper precision filter 2 and a booster pump 3, the oil inlet 4 of the booster pump 3 is connected to the oil outlet of the leak processing machine, and the paper precision filter 2 is provided with an oil outlet 5. The oil outlet 5 is connected to the oil inlet hole of the leakage nozzle processing machine through a pipeline, and the paper precision filter 2 is also provided with an oil inlet 6, and the oil inlet 6 is passed through a pipe The road is connected to the booster pump 3. The filter paper in the paper precision filter 2 has a pore size of 2um, and the powder filtration effect reaches over 99.99%. The filter pap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com