A kind of injection blow molding method of teee bellows

A technology of injection blow molding and bellows, which is applied in the field of injection blow molding of TEEE bellows, which can solve the problems of incorrect wall thickness control point, corrugated blowing of tube blank, and corrugated rupture of products, etc. The effect of reducing material waste and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Attached below Figures 1 to 7 Embodiments of the present invention will be further described.

[0030] A kind of injection blow molding method of TEEE bellows, comprises the steps:

[0031] Step 1. Tube blank forming: inject TEEE tube material into tube blank, and control the molding temperature to 245℃~280℃;

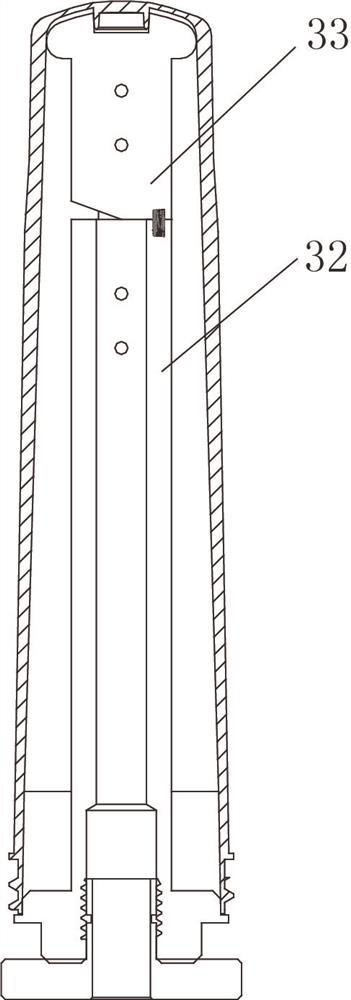

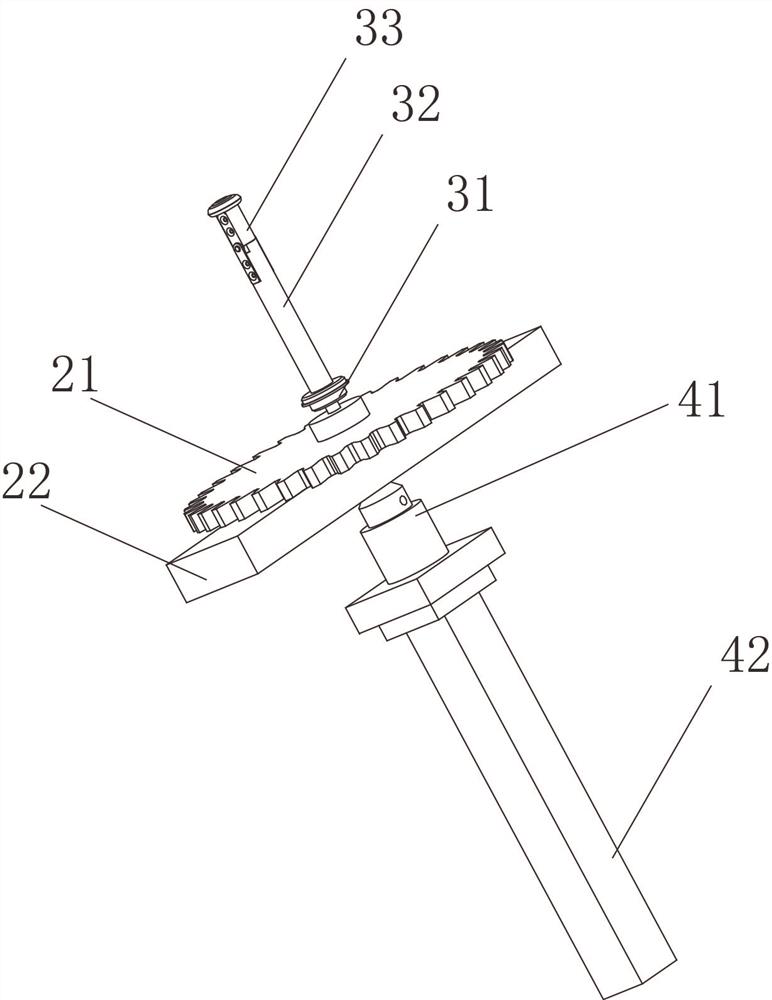

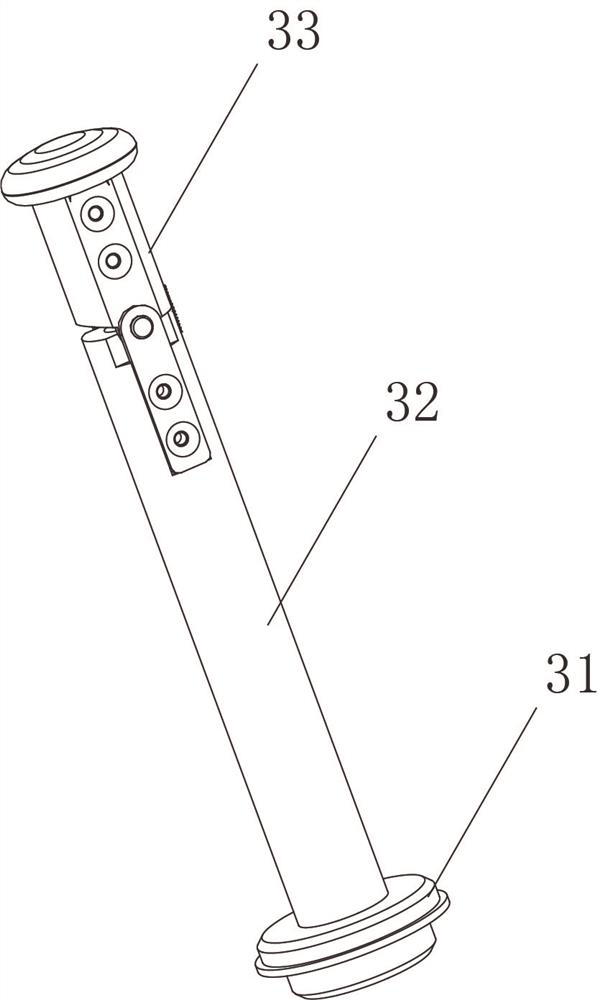

[0032] Step 2, tube blank softening: After demoulding the tube blank in step 1, put it into the blow molding tool through the automatic feeding mechanism, so that the tube blank is placed on the mandrel assembly on the top of the molding tool, and it is located in the circumferential direction of the mandrel assembly. The infrared tube heats the tube blank installed outside the blow molding tooling. The molding tooling includes a driven plate 21 and a support seat 22. The driven plate 21 is movably arranged on the support seat 22, and rotates on the support seat 22 by driving the chain, thereby Drive the tube blank set outside the mandrel assembly to rotate an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com