Cable duct sealant and method of use thereof

A cable tube and plugging agent technology, which is used in cable installation, cable installation devices, adhesives, etc., can solve problems such as poor environmental protection, short service life, fire resistance, smoke blocking, oil resistance, water resistance, and corrosion resistance. , to achieve the effect of excellent cost performance, high corrosion resistance and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

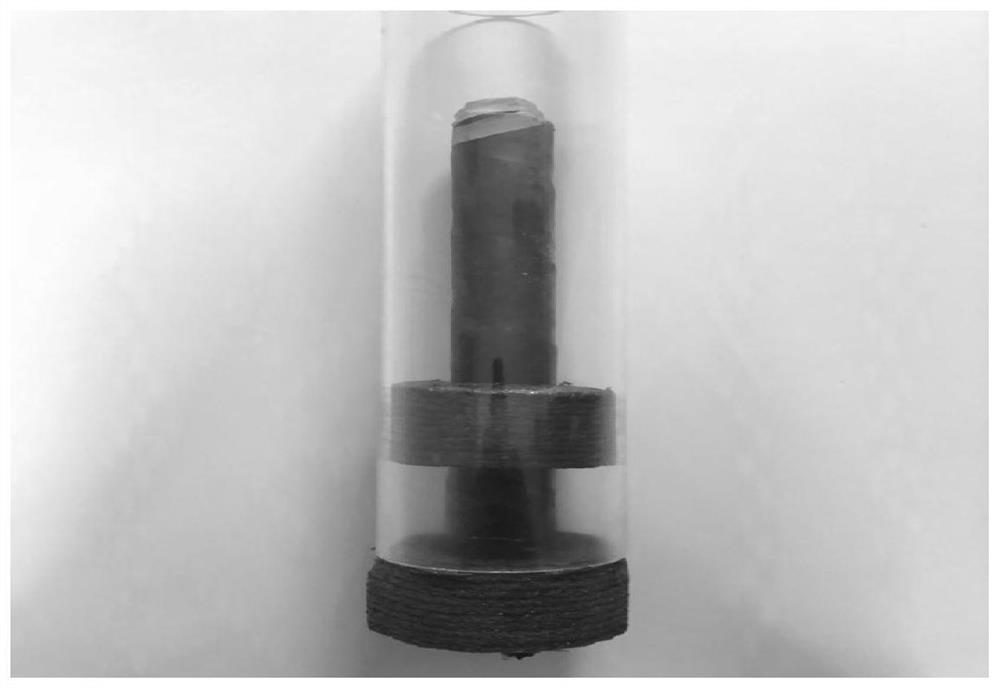

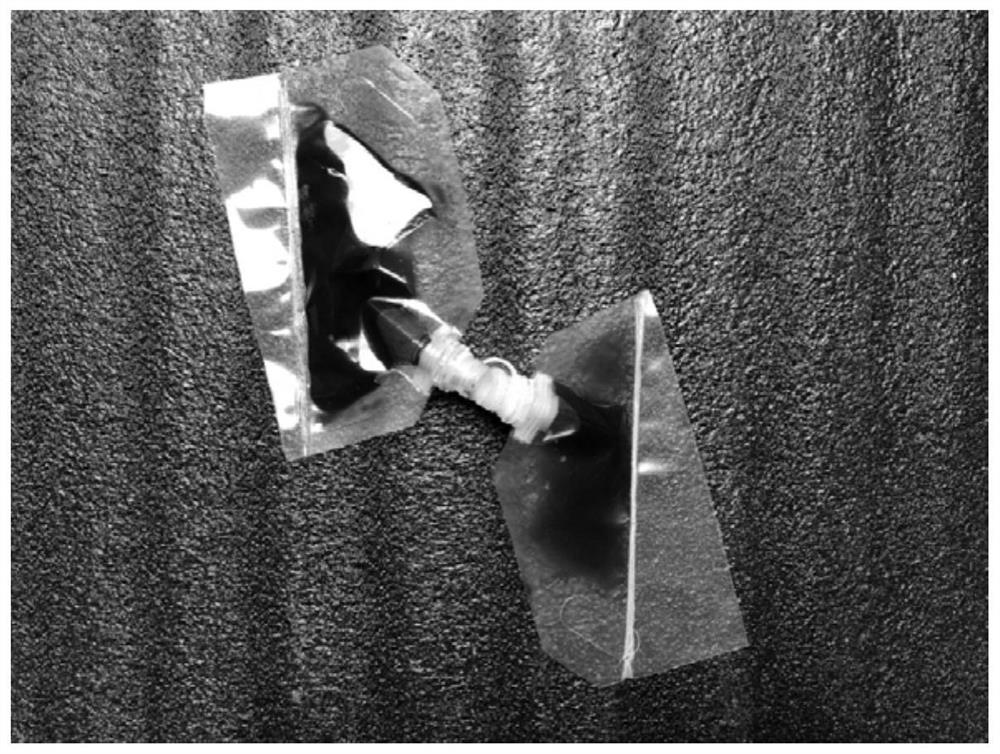

Image

Examples

Embodiment 1

[0039] The cable duct sealing agent consists of two components, A and B, in parts by weight, and the raw materials are as follows:

[0040] A component

[0041]

[0042] B component

[0043] Diphenylmethane diisocyanate (MDI) 0.507kg

[0044] Polyphenyl polymethylene polyisocyanate (PAPI) 0.045kg

[0045] Prepare A and B two components into W material and B material respectively, and its preparation method is:

[0046] (1) Preparation of material W: weigh component A in parts by weight and stir evenly in a stainless steel reaction kettle. The stirring speed is 3000~4000n / min; the stirring time is 1~2min. Fill W material in the plastic bag that is provided with discharge port and seal and preserve.

[0047] (2) Preparation of material B: weigh component B in parts by weight and stir evenly in a stainless steel reaction kettle. The stirring speed is 3000~4000n / min; the stirring time is 1~2min. Fill material B in a plastic bag with a discharge port and keep it sealed. ...

Embodiment 2

[0058] The cable duct sealing agent consists of two components, A and B, in parts by weight, and the raw materials are as follows:

[0059] A component

[0060]

[0061] B component

[0062] Diphenylmethane diisocyanate (MDI) 0.5432kg

[0063] Polyphenylpolymethylene polyisocyanate (PAPI) 0.048kg

[0064] The method of preparation and use of the plugging agent in Example 2 is basically the same as in Example 1, except that the two components A and B are mixed together at a mass ratio of 100:70. The physical and chemical properties of the plugging agent obtained in Example 2 are shown in Table 2.

[0065] Table 2 The physical and chemical properties of the plugging agent obtained in Example 2

[0066]

Embodiment 3

[0068] The cable duct sealing agent consists of two components, A and B, in parts by weight, and the raw materials are as follows:

[0069] A component

[0070]

[0071] B component

[0072] Diphenylmethane diisocyanate (MDI) 0.579kg

[0073] Polyphenylpolymethylene polyisocyanate (PAPI) 0.0514kg

[0074] The preparation and use method of the plugging agent in Example 3 are basically the same as in Example 1, except that the two components A and B are mixed together at a mass ratio of 100:75. The physical and chemical properties of the plugging agent obtained in Example 3 are shown in Table 3 below.

[0075] Table 3 Physical and chemical properties of the plugging agent obtained in Example 1

[0076]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com