Control method for stable operation of gasification device after shutdown of partial coal pipelines

A gasification device and a stable operation technology, applied in the gasification of granular/powdered fuels, the manufacture of combustible gases, the petroleum industry, etc., can solve the fluctuations and fluctuations of the gasification system, reduce the risk of water wall lining and gasification burner ablation and other problems, to achieve the effect of simple operation and good resistance to system fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

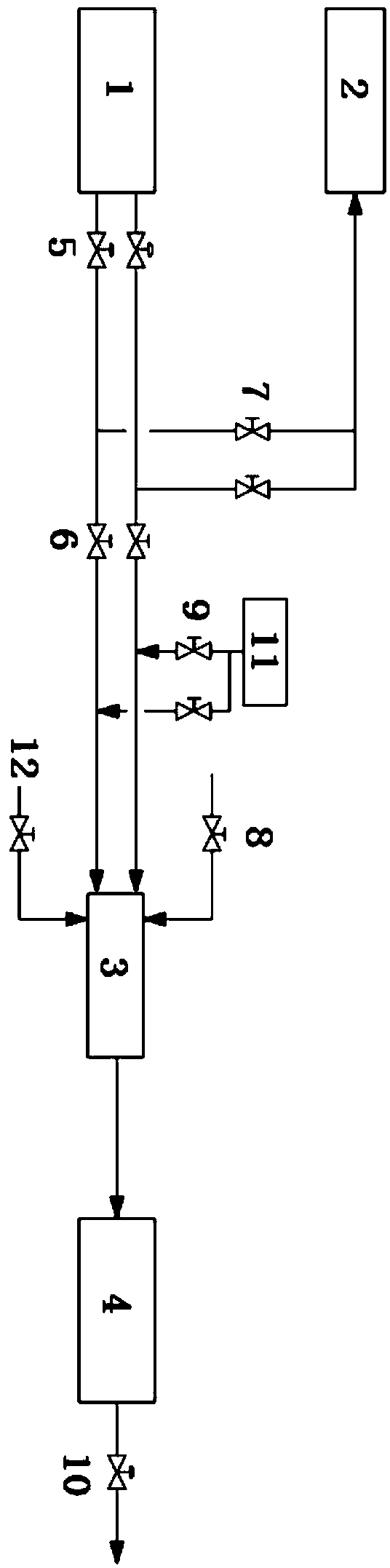

[0042] A coal gasification unit with a daily processing capacity of 1,000 tons. There are 2 pulverized coal pipelines with a gasification pressure of 4.0MPag, and pulverized coal is used as feed. A gasification burner is installed on the top of the gasifier, two pulverized coal pipelines and two corresponding oxygen In the pipeline, when a single pulverized coal pipeline jumps, the gasification unit operates stably and controllably. The main steps are as follows:

[0043] (1) Switch the system pressure regulating valve to manual control, the valve opening is 20%, and the gasification system pressure is reduced to ~3.8MPag;

[0044] (2) The skipped coal line corresponds to the oxygen cutoff, and the skipped coal line nitrogen (or CO 2 ) Purge;

[0045] (3) Increase the pulverized coal and oxygen load of the operating coal line to protect the gasifier burner;

[0046] (4) After the fault processing of the skipping coal line is completed, based on the configuration of the feeding tank, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com