A kind of cross-shaped silica gel biaxial tensile test piece and its preparation and tensile test method

A biaxial stretching and cross-shaped technology, which is applied in the preparation of test samples, the use of stable tension/compression to test the strength of materials, sampling, etc., can solve the problems of stretching asymmetry, no test data, lack of etc. problem, to achieve the effect of increasing the strain level, solving the problem of stretching asymmetry, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

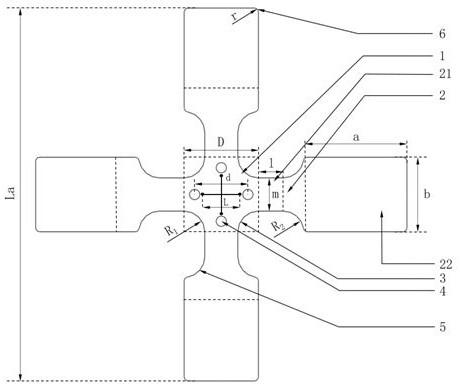

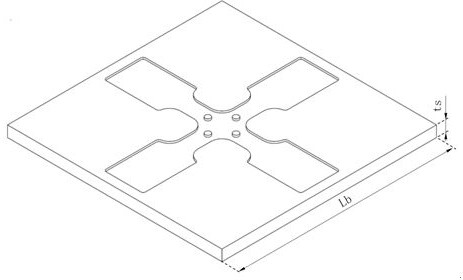

[0049] see Figure 1 to Figure 7 , the cross-shaped silica gel biaxial tensile test piece includes a central area 1 and four extension walls 2, characterized in that the central area 1 is a square, and the four extension walls 2 surround the central area 1 outwards Extending and forming a cross shape, the junction of the four extension walls 2 has four edge transition fillets 3, and the middle part of the test piece has four round holes 4 distributed symmetrically along the central circumference of the test piece on the cross axis. , the four circular holes 4 are located inside the central area 1, the part of the extension wall 2 close to the central area 1 is a connection area 21, the end of the extension wall 2 is a clamping area 22, and the connection area 21 is connected to the clamping area. There are transition arcs 5 on both sides of the connecting part of the area 22, and the clamping area 22 is clamped by four clamps in the biaxial tensile testing machine, and the cor...

Embodiment 2

[0051] This embodiment is basically the same as Embodiment 1, and the special feature is: the side length of the central region is defined as the center distance of the cross axis of the edge transition fillet 3, the overall thickness of the test piece is a given value, The initial cross-sectional area is defined as the product of the side length of the central region 1 and the overall thickness, and the gauge length is defined as a length symmetrically distributed along the cross axis at the center of the test piece.

Embodiment 3

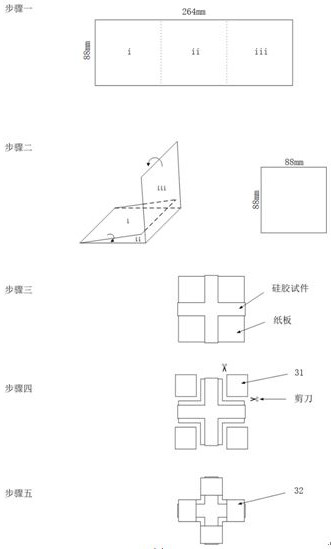

[0053] The preparation method of the cross-shaped silica gel biaxial tensile test piece is used to prepare the above-mentioned test piece, and is characterized in that it includes the following preparation steps:

[0054] Step 1. Utilize three-dimensional modeling software to design the preparation mold model of the test piece, and manufacture the mold on the duralumin plate by milling;

[0055] Step 2. Pour the uncured silicone liquid into the beaker in equal proportions, and stir until uniform;

[0056] Step 3. Pour the mixed silicone liquid into the mold so that the silicone just fills the groove on the mold;

[0057] Step 4, put the mold containing the silicone liquid into a vacuum drying oven, start the vacuum pump, and vacuum the inside of the box for 10 minutes to get rid of the air bubbles inside the silicone liquid on the mold;

[0058] Step 5. Take out the mold from the vacuum drying oven, place the mold on a horizontal plane, and press another hard aluminum plate w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com