300-series austenitic stainless steel solid solution and stabilization heat treatment process

An austenitic stainless steel, solution heat treatment technology, used in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of large internal stress, intergranular stress corrosion cracking, high temperature recrystallization of pipes, etc. The tendency of stress corrosion cracking, the reduction of residual deformation internal stress, the effect of avoiding high temperature recrystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention are described clearly and completely below.

[0028] A heat treatment process for solid solution and stabilization of 300 series austenitic stainless steel, the process steps are as follows:

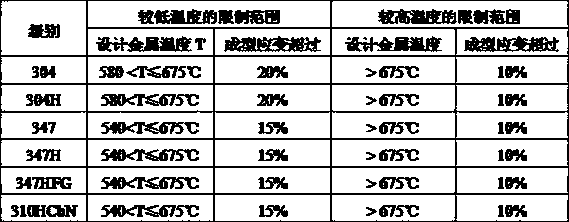

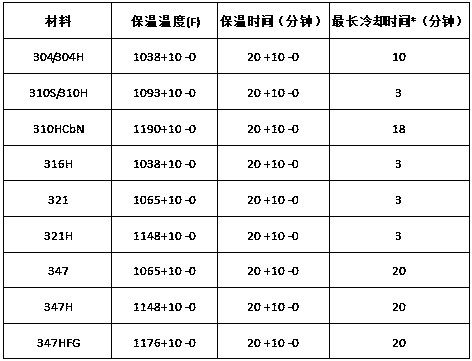

[0029] Step 1: Determine whether solid solution is required for the stainless steel pipe to be processed: For austenitic stainless steel materials formed by cold / hot processing, when the forming strain and design metal temperature meet the requirements in Table 1 at the same time, the cold / hot forming must be performed If solution heat treatment is done in the area, solution heat treatment must be done to the cold / hot forming area. The materials of the stainless steel pipes to be processed include 304 / 304H, 310S / 310H, 310S / 310H, 316H, 321, 347, 347H and 347HFG Material, Table 1 is as follows:

[0030]

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com