Steel pipe RPC frame dense rib composite shear wall

A technology of shear walls and steel pipes, which is applied to walls, building components, and earthquake resistance. It can solve problems such as weak energy consumption and earthquake resistance, inability to repair and reinforce, and increase the workload of post-earthquake reconstruction, so as to achieve reasonable bearing capacity and rigidity. matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

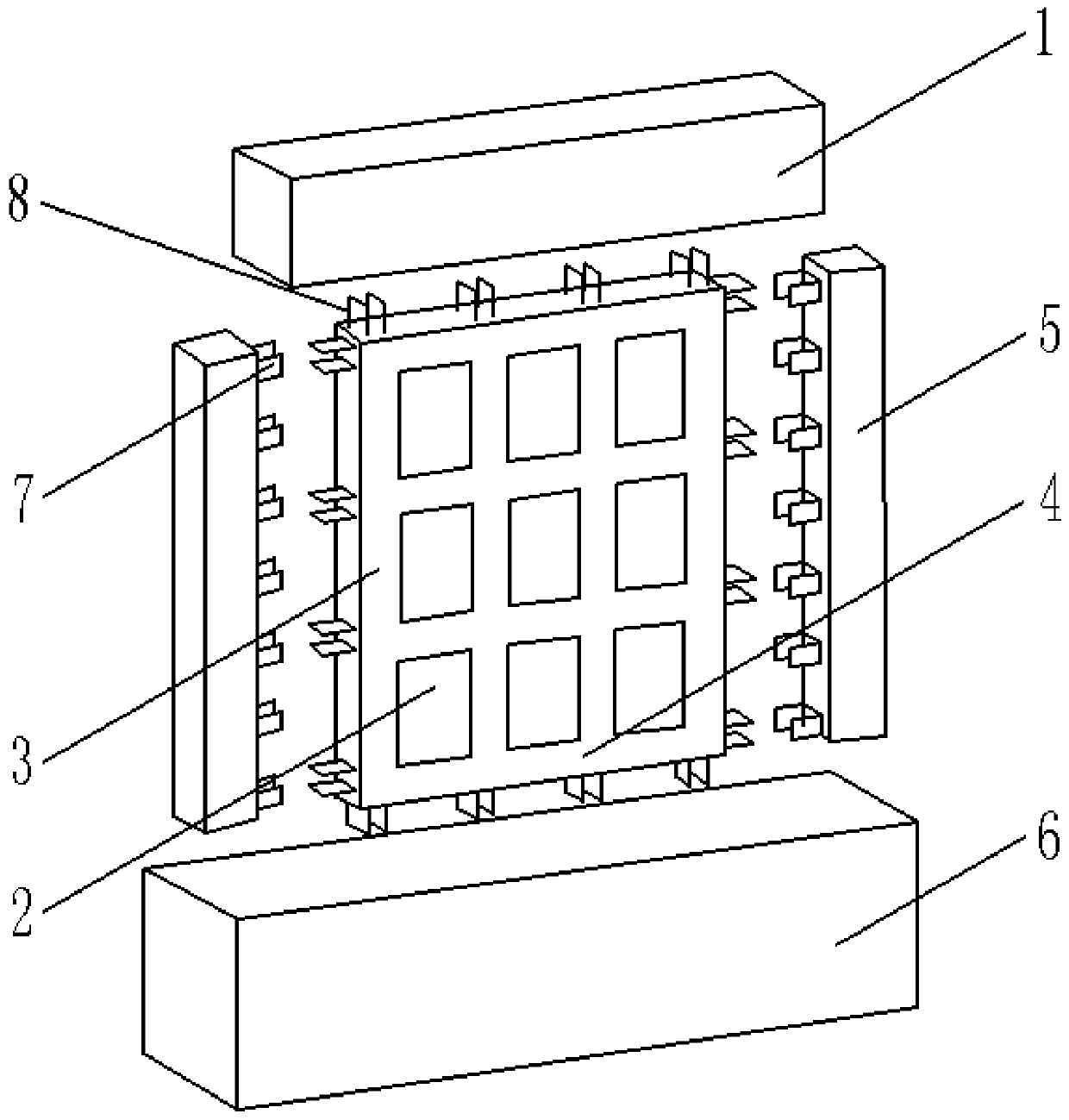

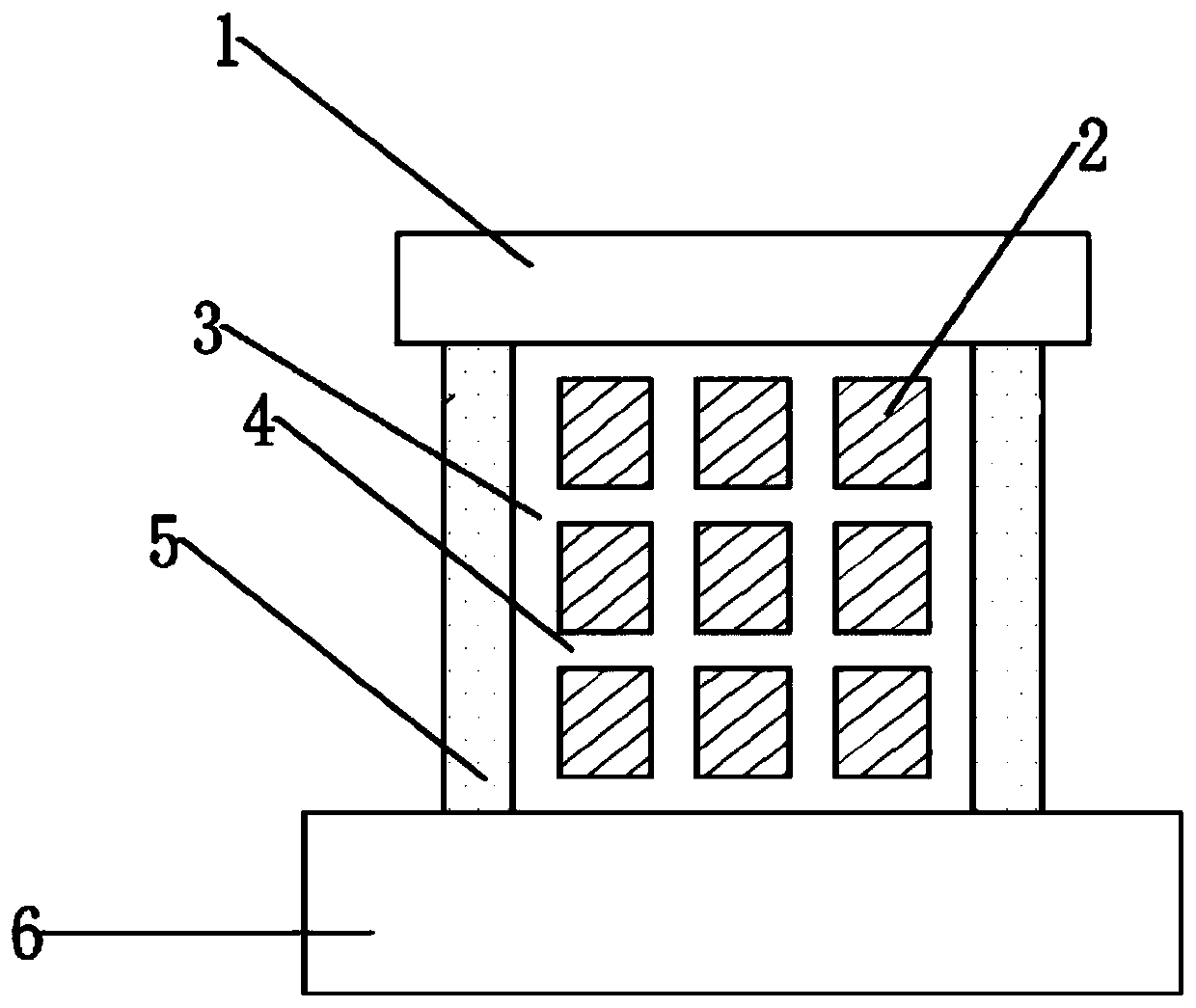

[0032] The embodiment of the present invention provides a steel pipe RPC frame dense rib composite shear wall, see figure 1 , including steel pipe RPC frame columns 5 and densely ribbed composite panels between the steel pipe RPC frame columns 5, steel pipe RPC frame columns 5 and densely ribbed composite panels are connected by U-shaped shear keys 7, and are poured into one body with concrete; The densely ribbed composite panel includes a plurality of rib beams 4 and rib columns 3, and the plurality of rib beams 4 and rib columns 3 form a whole rectangular rib grid including a plurality of rectangular rib grids, and each rectangular rib grid is filled with RPC block 2, and pour the RPC block 2, the rib column 3 and the rib beam 4 into one body with concrete.

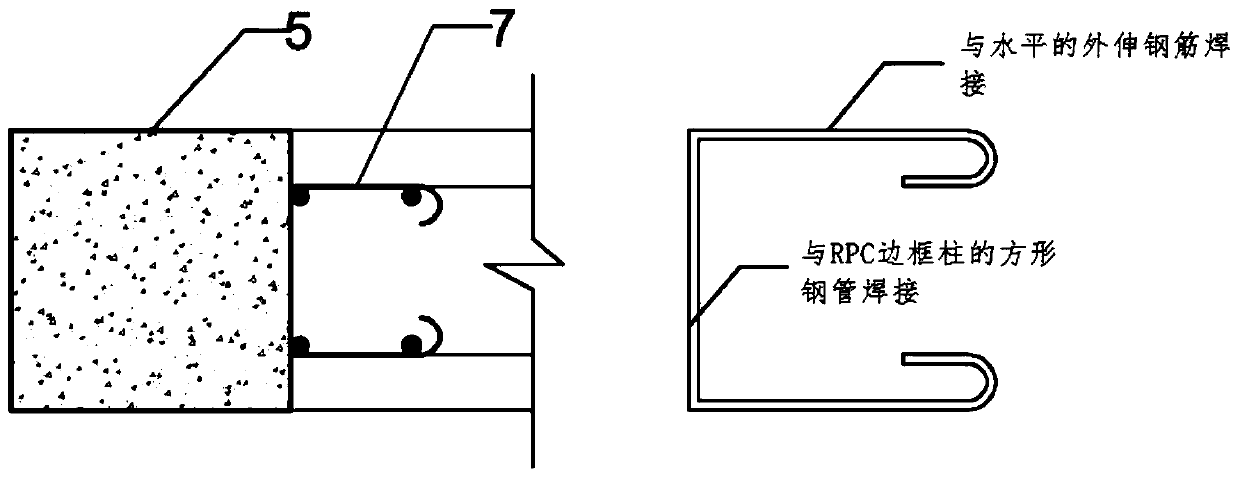

[0033] Further, the plurality of rib beams 4 and rib columns 3 are bound into steel cages by several horizontal steel bars and several vertical steel bars and are casted with concrete. Reinforcing bar 8, the part where...

Embodiment 2

[0045] The rest of this embodiment is the same as that of Embodiment 1, the difference is that it uses a three-rib beam and three-rib column structure to form a cross-rib structure, that is, the three-rib beam and three-rib column structure is formed by binding steel bars on site to form a cross-bar cage frame. , and then fill the prefabricated RPC blocks 2 into the four rectangular ribs in the cross rib structure, and pour them on the wooden formwork, so that except for the frame, the remaining rib beams 4 and rib columns 3 and the RPC block 2 At this time, the horizontal steel bars and vertical steel bars of the frame are exposed, and then the uncast rectangular ribs are connected to the steel pipe RPC frame column 5 with U-shaped shear keys 7, that is, the U-shaped ribs are first connected The U-shaped closed end of the U-shaped shear key 7 is welded on the square steel pipe of the steel pipe RPC frame column 5, and then the vertical reinforcement of the frame is wrapped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com