Multi-reactor vacuum furnace for preparing silicon monoxide

A multi-reactor, silicon monoxide technology, applied in the direction of silicon oxide, furnace, furnace type, etc., can solve the problems of low single furnace output, low production efficiency, small furnace volume, etc., to improve production efficiency and reduce production capacity Consumption, improve the effect of collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

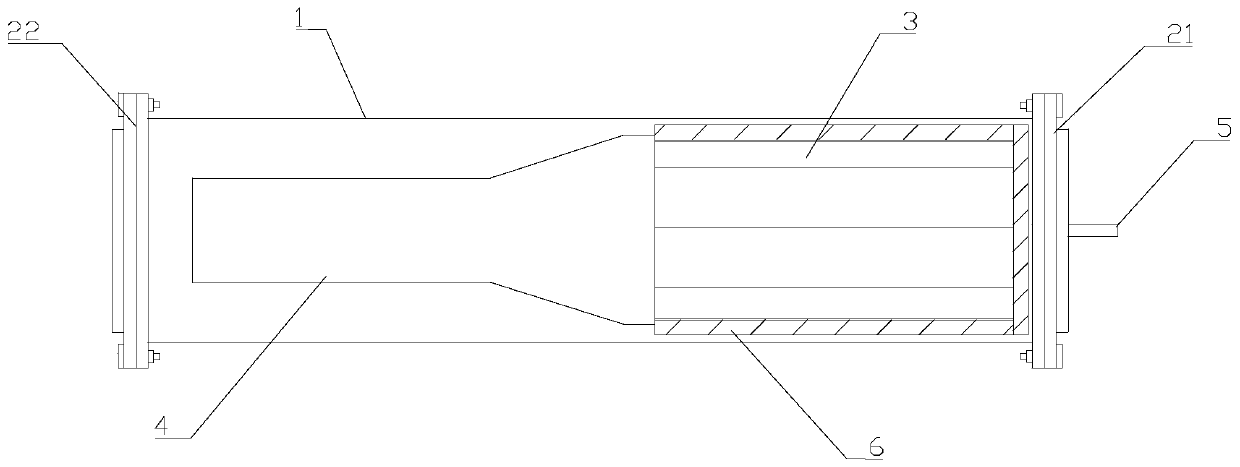

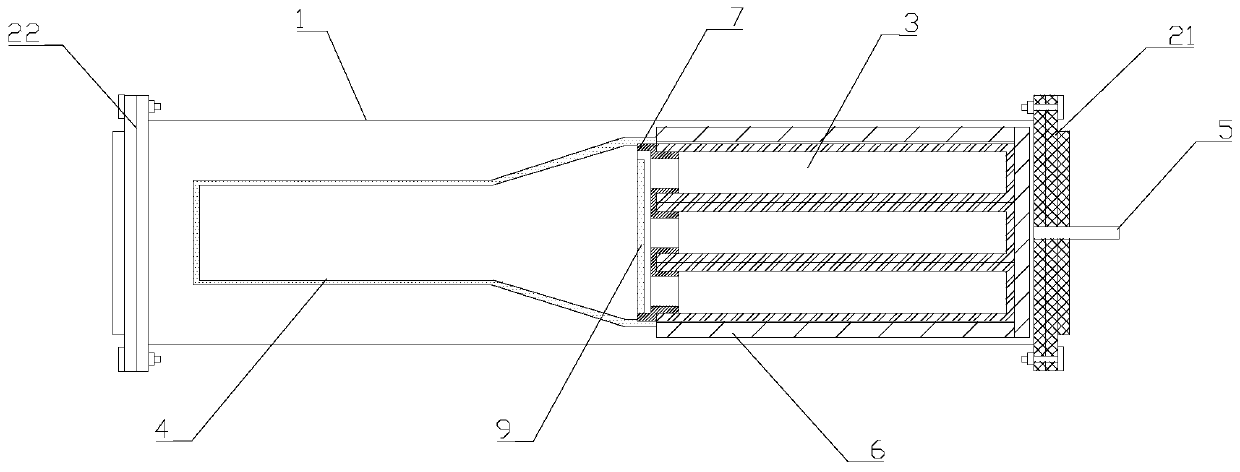

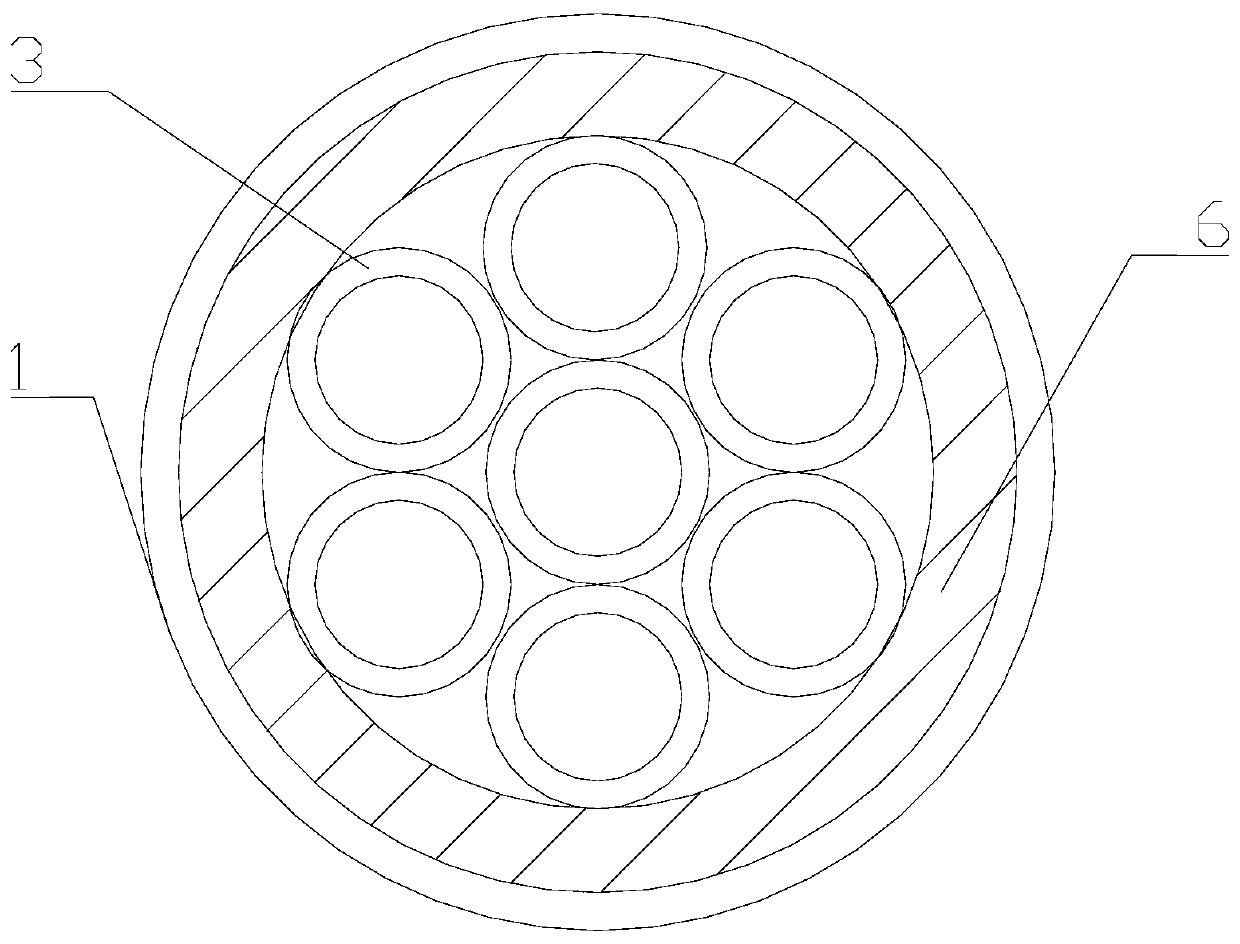

[0024] refer to Figure 1-5 , a multi-reactor vacuum furnace for producing silicon monoxide, comprising: a furnace body 1, a plurality of heating reactors 3, a collector 4, and a vacuum device 5, and one end of the furnace body 1 is provided with a first furnace cover 21 , the other end of the furnace body 1 is provided with a second furnace cover 22, a plurality of heating reactors 3 are closely packed and arranged in the furnace body 1, and the collector 4 is arranged in the furnace body 1, and each heating reactor 3 is connected with the collector 4 connected, a plurality of heating reactors 3 and collectors 4 jointly form a closed space, a vacuum device 5 is arranged outside the furnace body 1, and the vacuum device 5 communicates with the furnace body 1.

[0025] In the present invention, each heating reactor 3 is communicated with the collector 4, and multiple heating reactors 3 and collectors 4 jointly form a closed space 4, and during the reaction, multiple heating rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com