Micro-nano compression device

A compression device and micro-nano technology, applied in the field of biological sciences, can solve the problems of limited compression force, sample temperature rise, movement, etc., and achieve good compression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

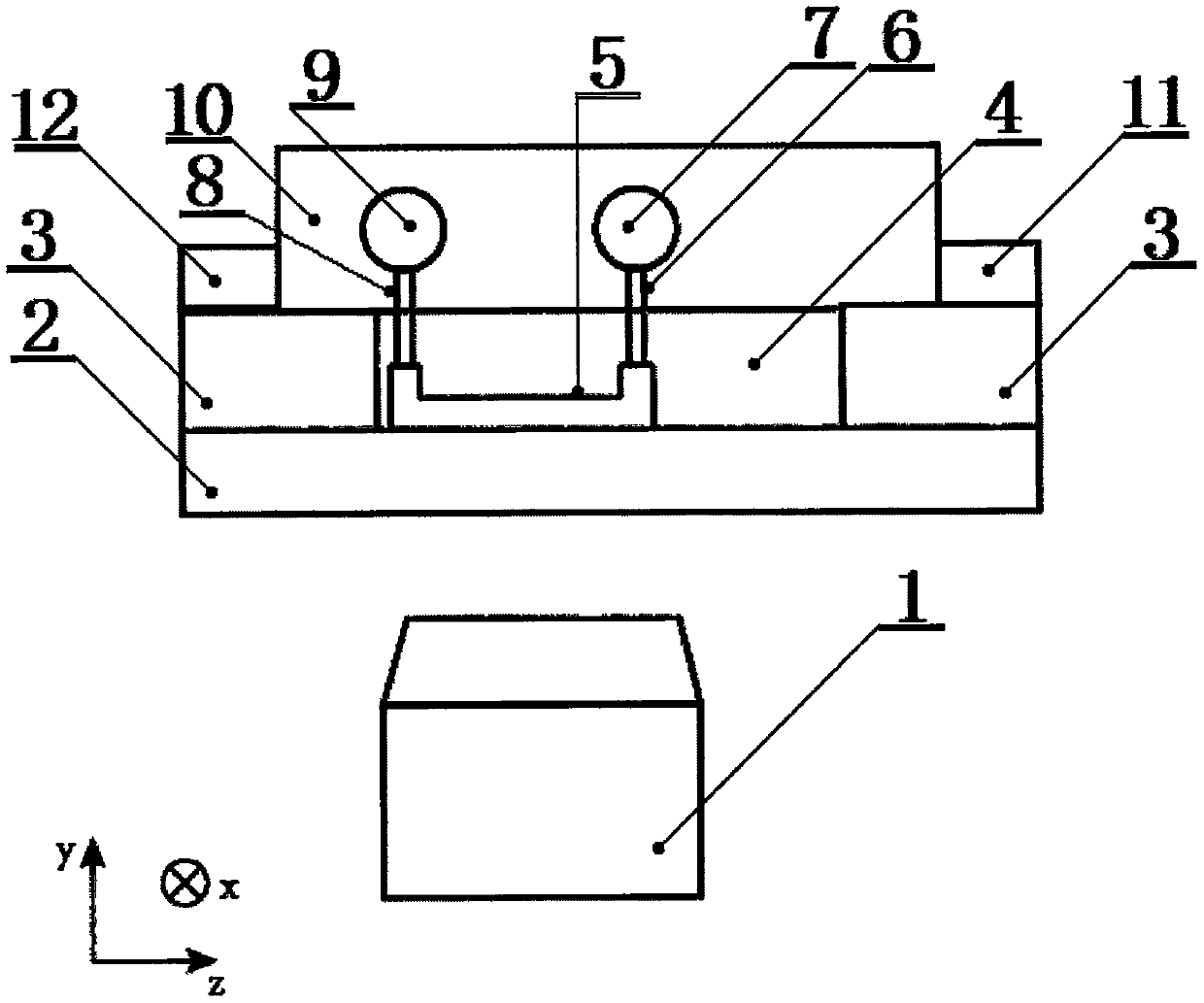

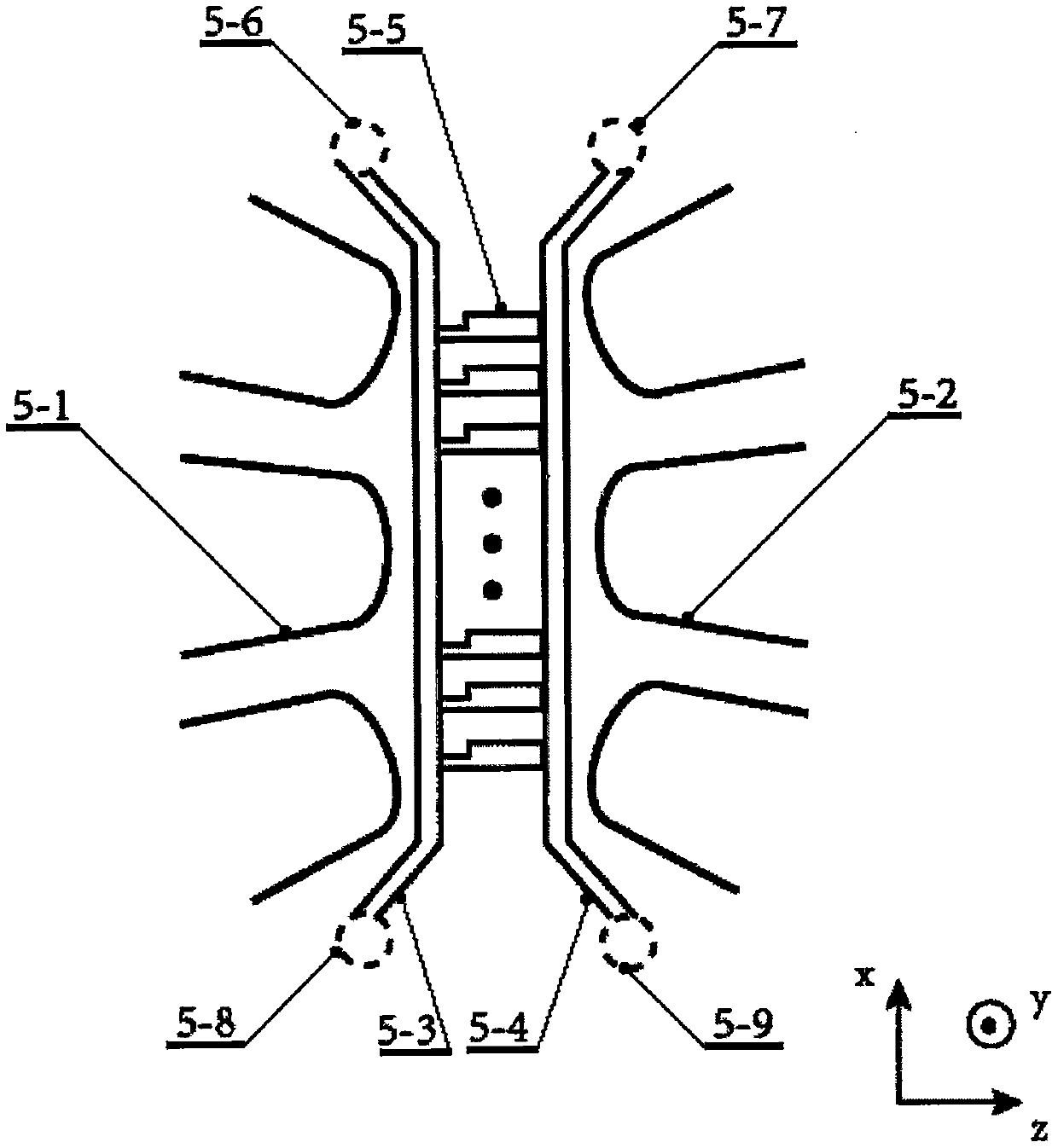

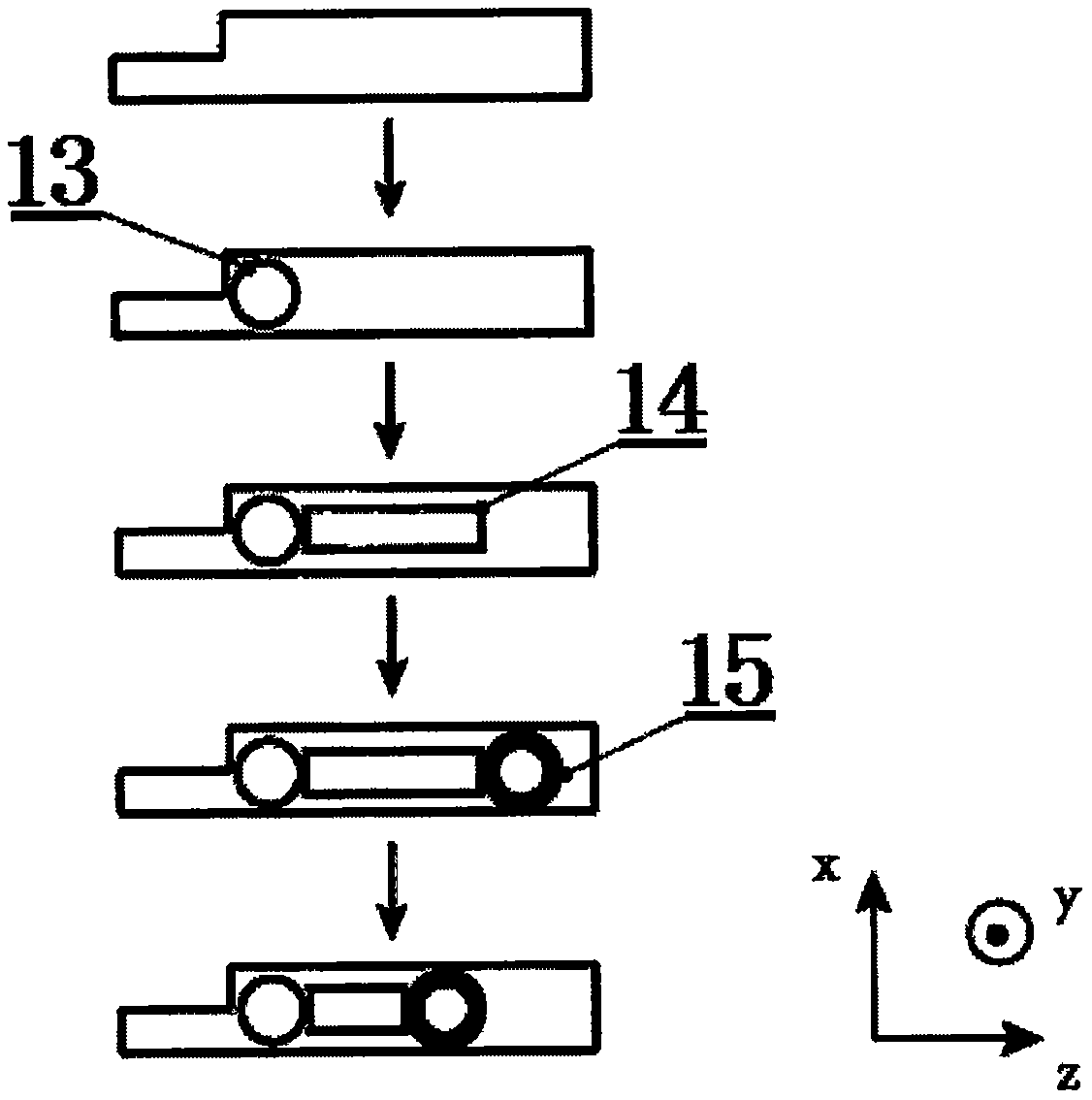

[0022] like figure 1 It is a schematic diagram of the present invention, including optical microscope (1), glass substrate (2), metal foil (3), filling layer (4), micro compressor (5), liquid inlet pipe (6), liquid inlet (7) , liquid outlet pipe (8), liquid outlet (9), protective layer (10), electromagnet I (11), electromagnet II (12), voltage source and cable, xyz is a three-dimensional coordinate system, and the compression experiment material has high Molecular spheres (13), macromolecular samples (14), magnetic spheres (15) and liquid, a microcompressor (5) is connected to the middle position above the glass substrate (2), and deposits with a thickness of The metal foil (3) of 500 microns, the remaining space of 500 microns height above the glass substrate (2) is a filling layer (4), and the filling layer (4) completely covers the microcompressor (5), and the filling layer (4) is Siloxane material; the liquid inlet (7) is connected to the port II (5-7) of the micro compre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com