Heat dissipation structure of magnetic cavity in magnetic coupling homogenizer

A heat dissipation structure and homogenizer technology, applied in mixers, mixer accessories, dissolving and other directions, can solve the problems of shortened bearing service life, damage to bearings, small pressure difference of homogenizers, etc., to ensure circulation and prevent fluid leakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

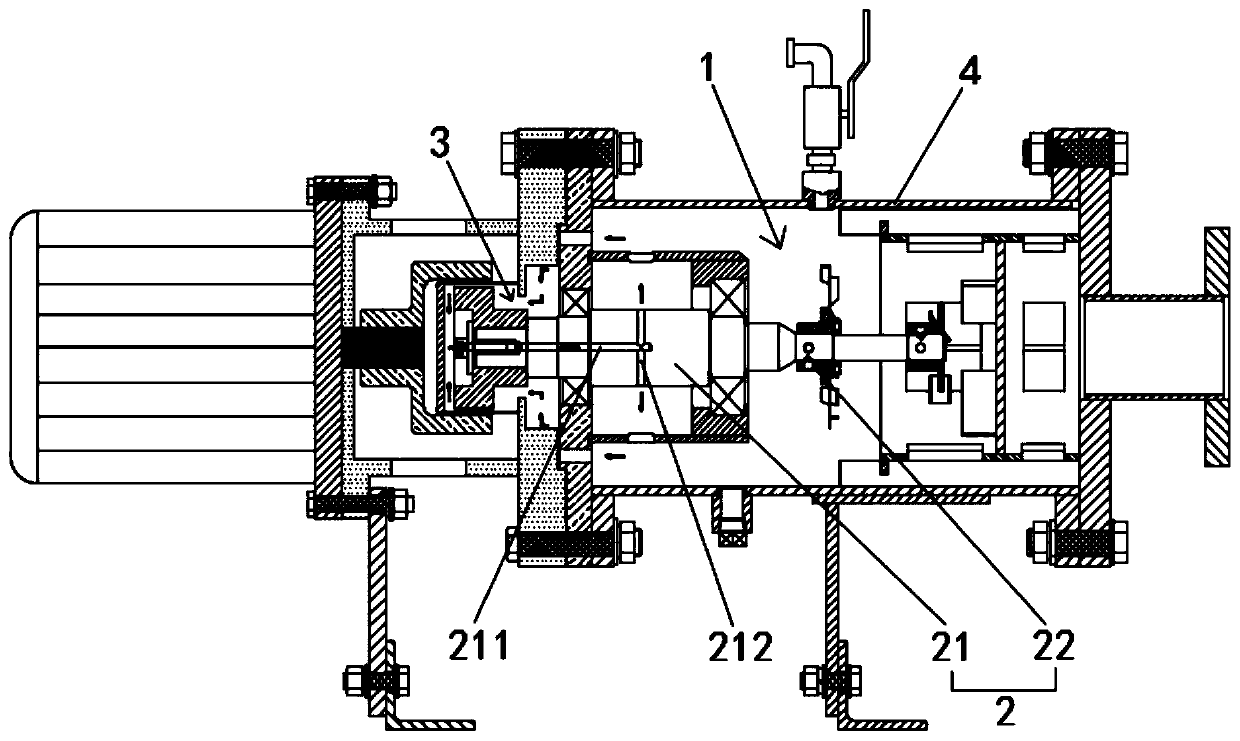

[0042] Such as figure 1 , figure 2 As shown, this embodiment discloses a heat dissipation structure of a magnetic chamber in a magnetic coupling homogenizer, including a fluid homogenization chamber 1, a homogenization transmission mechanism 2, and a fluid heat exchange chamber 3; the fluid heat exchange chamber 3 is connected to the The fluid homogeneous cavity 1 is connected, and forms a heat exchange inlet fluid channel and a heat exchange outlet fluid channel;

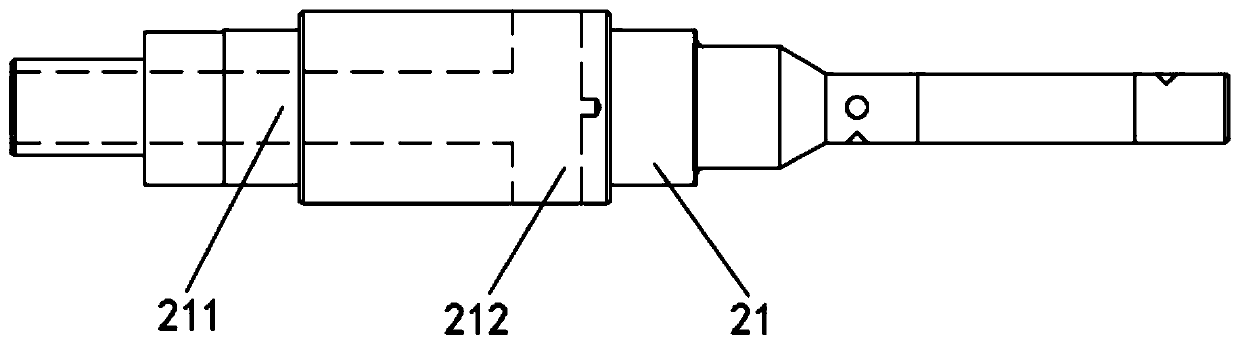

[0043] The homogeneous transmission mechanism 2 includes a main shaft 21 and a homogenizer impeller 22, and the homogenizer impeller 22 is arranged on the main shaft 21;

[0044] The terminal end of the main shaft 21 protrudes into the fluid homogeneous chamber 1 and causes the homogenizer impeller 22 to be limited in the fluid homogeneous chamber 1; the initial end of the main shaft 21 is limited in the fluid homogeneous chamber 1 In the fluid heat exchange cavity 3; the interior of the main shaft 21 is hollow,...

Embodiment 2

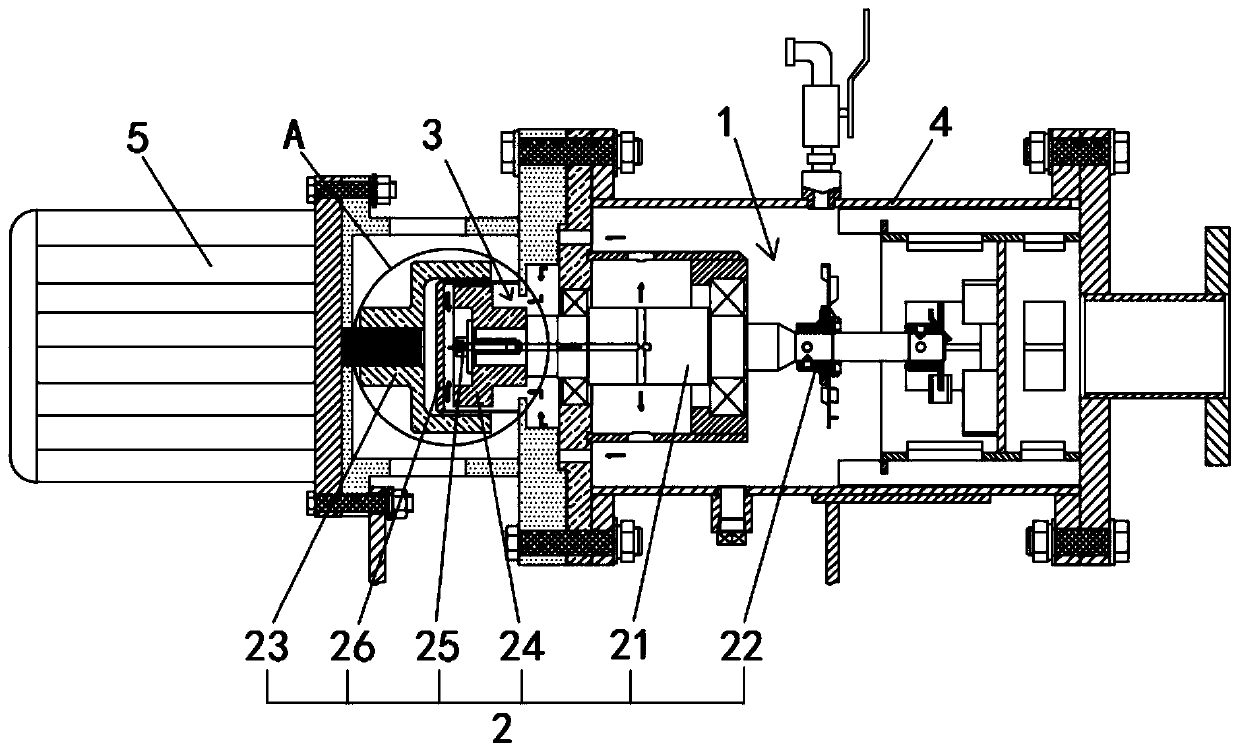

[0059] Such as Figure 4 , Figure 5 As shown, the difference between this embodiment and the first embodiment is that a spacer 26 is provided between the outer magnetic rotor 23 and the inner magnetic rotor 24, and the spacer 26 connects the outer magnetic rotor 23 and the inner magnetic rotor 24 The gap between is divided into a first gap and a second gap;

[0060] The spacer 26 is a cavity structure with one end open, and the open end of the spacer 26 is connected to the side wall of the fluid heat exchange chamber 3 to form a sealed heat exchange channel; the heat exchange channel, the second gap, the fluid The homogeneous chamber 1 is connected;

[0061]In this embodiment, the arrangement of the isolation sleeve 26 can prevent the fluid from leaking while the fluid is flowing in the fluid heat exchange cavity 3 .

[0062] Further, the head of the bolt 25 is fixed to the starting end of the inner magnetic rotor 24, and the stem of the bolt 25 is sleeved in the feed hole...

Embodiment 3

[0065] Such as image 3 , Figure 9 , Figure 10 As shown, the heat dissipation structure is integrated in the homogenizer body 4; the homogenizer body 4 is provided with a liquid inlet 41 and a liquid outlet 42; the output shaft of the motor 5 is connected to the outer magnetic rotor 23 The starting end is fixed, the liquid inlet 41 is arranged on the outer surface of the homogenizer body 4, and the liquid outlet 42 is arranged at one end of the homogenizer body 4; the other end of the homogenizer body 4 The port is also provided with a flange integrally formed with it, and the other side of the flange is also fixed with a motor connection plate, and the output end of the homogeneous transmission mechanism 2 is arranged in the cavity of the motor connection plate, and the There are also a plurality of cooling holes on the upper and lower sides of the motor connection plate, so as to facilitate the external cold air to enter the motor connection plate and exchange heat with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com