Self-adaptive automatic cleaning device for vehicle wheel forging die

An automatic cleaning and self-adaptive technology, applied in the direction of automatic grinding control device, grinding drive device, forging/pressing/hammer device, etc., can solve the problems of difficult mold surface cleaning, difficult cleaning, time-consuming and labor-intensive, etc. , to meet the requirements of high-efficiency production, improve the degree of automation, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

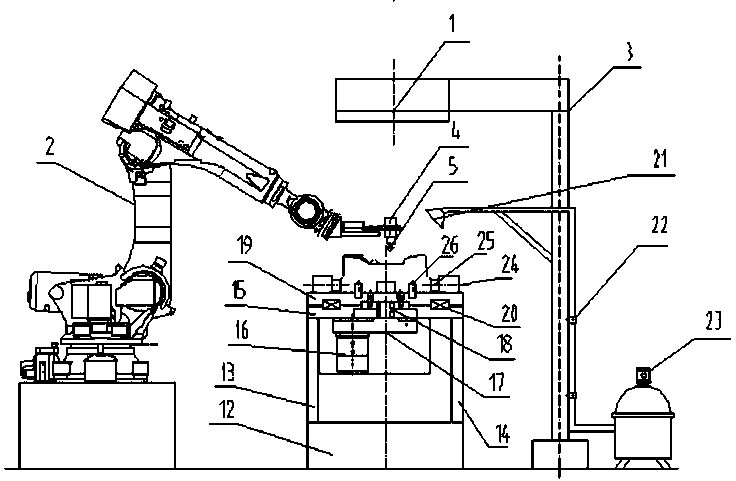

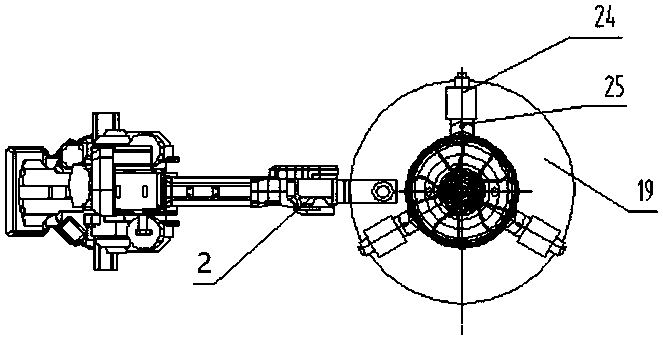

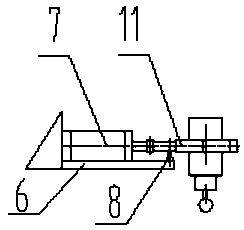

[0026] Attached below in conjunction with the instructions Figure 1-4 Illustrate Example 1 of this application:

[0027] An adaptive automatic cleaning device for wheel molds includes a main control unit, a camera device 1, a robot arm 2, a cleaning component, a connecting component, a bracket 3, a mold rotating mechanism, a mold fixing component, and a cleaning fluid spraying mechanism.

[0028] The main control unit signally connects the camera equipment 1, the robot arm 2, the cleaning component, the mold rotation mechanism, and the mold fixing component. The main control unit includes a storage unit. The main control unit receives the image of the wheel mold captured by the camera device 1 and the main control unit The image information stored in the storage unit is compared, the shape and contour information of the wheel mold are recognized, the model information of the wheel mold is recognized, and the matching control robot arm 2 movement trajectory and the control cleaning...

Embodiment 2

[0039] Embodiment 2: The difference between the technical solution in Embodiment 2 and Embodiment 1 is that the composition structure of the transmission mechanism 17 is different. In specific embodiment 2: the transmission mechanism 17 includes a pinion shaft, a large gear shaft, a small gear, a belt, and a large gear. The output shaft of the servo motor 16 is connected to the pinion shaft, and the small gear and the large gear are connected by a belt. The output shaft of the gear is fixedly connected to the lower end of the coupling 18. The small gear in the transmission mechanism 17 drives the large gear to rotate through a belt, and the rest of the components and their structures and connections are the same as the first embodiment.

Embodiment 3

[0040] Embodiment 3: The difference between the technical solution in Embodiment 3 and Embodiment 1 is that the composition structure of the transmission mechanism 17 is different. In specific embodiment 3: the transmission mechanism 17 includes a pinion shaft, a large gear shaft, a pinion, a chain, and a large gear. The output shaft of the servo motor 16 is connected to the pinion shaft, and the pinion and the large gear are connected by a chain belt. The output shaft of the big gear is fixedly connected to the lower end of the coupling 18. The small gear in the transmission mechanism 17 drives the large gear to rotate through a chain, and the rest of the components and their structures and connections are the same as those in the first embodiment.

[0041] In summary, the present invention provides an adaptive automatic cleaning device for wheel forging molds, which can solve the problems in the background art. The present invention can spray cleaning fluid to the mold to clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com