Soldering iron core, soldering system and temperature control method of soldering iron

A temperature control method and a technology for soldering iron cores, which are applied in the field of soldering iron cores and can solve the problems of inability to obtain them.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

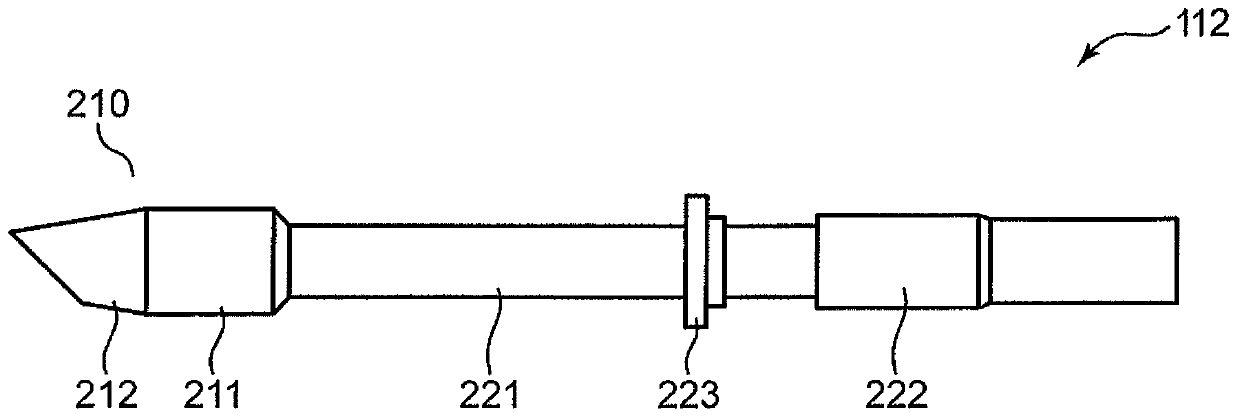

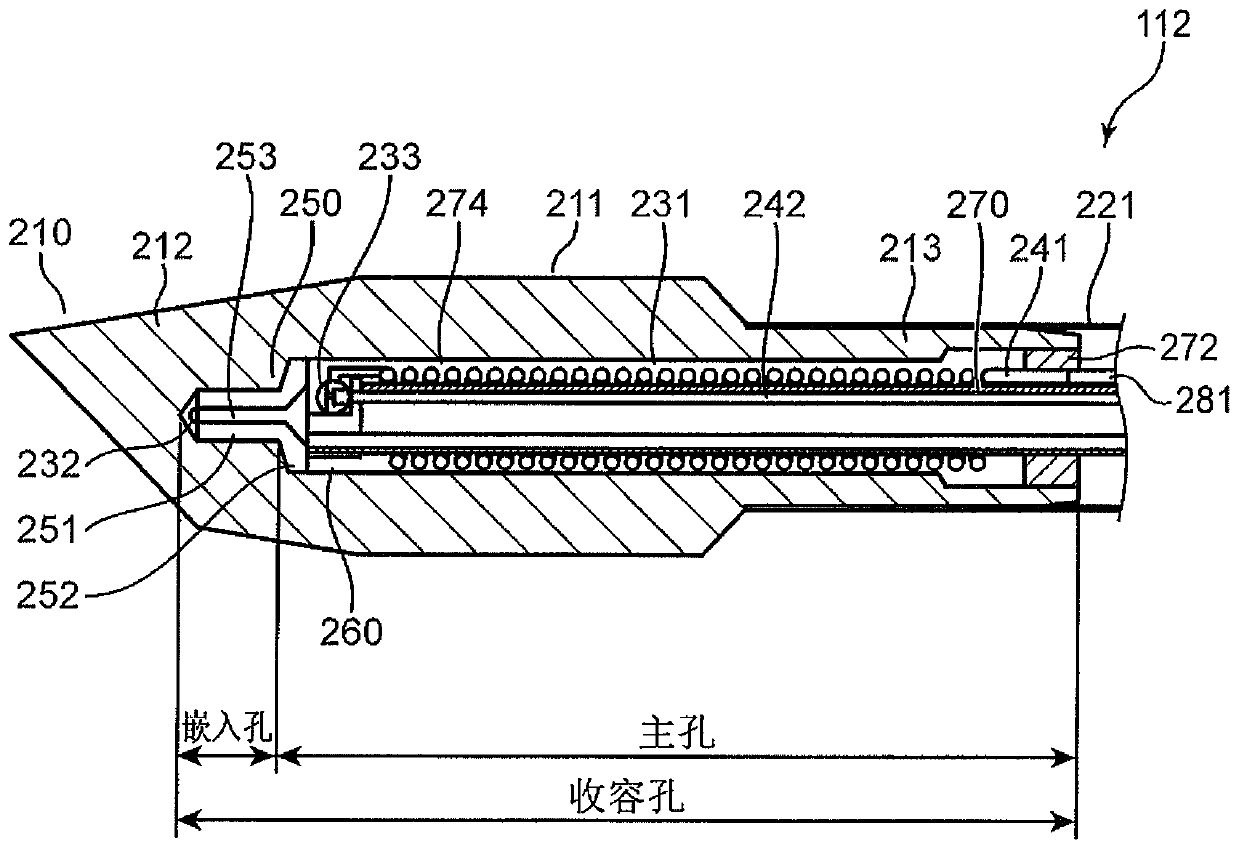

[0055] figure 1 It is a side view of the soldering iron core 112 for soldering irons. refer to figure 1 , Image 6 and Figure 11 Soldering iron core 112 will be described.

[0056] The soldering iron core 112 includes a soldering iron tip 210 at the distal end. The soldering iron core 112 further includes: a soldering iron core barrel 221 extending from the soldering iron tip 210 to the base end side; and a connector barrel 222 attached to the base end portion of the soldering iron core barrel 221 . The soldering iron core 112 has a connector assembly 280 provided in the connector barrel 222 (see Image 6 ). The space in the soldering iron core barrel 221 is used for wiring from the connector assembly 280 to the distal end side.

[0057] The connector barrel 222 of the soldering iron core 112 is securely embedded in the Figure 11 The structure of the handle 111 is shown. If the connector barrel 222 is inserted into the handle 111, the soldering iron core 112 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com