Pantograph insulation bow angle and pantograph

A pantograph and angle end technology, applied in the field of mechanical structure, can solve the problems of high cost of new manufacture and maintenance, non-wear-resistant bow angle, discharge at the bottom of the bow angle, etc., to reduce the cost of new manufacture and maintenance, good manufacturability, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

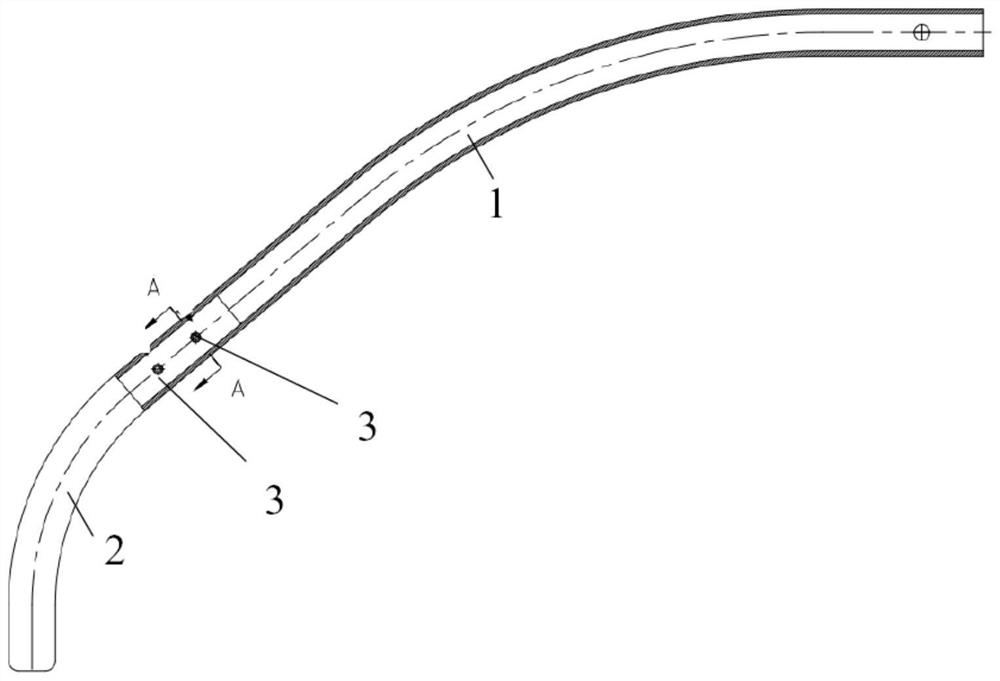

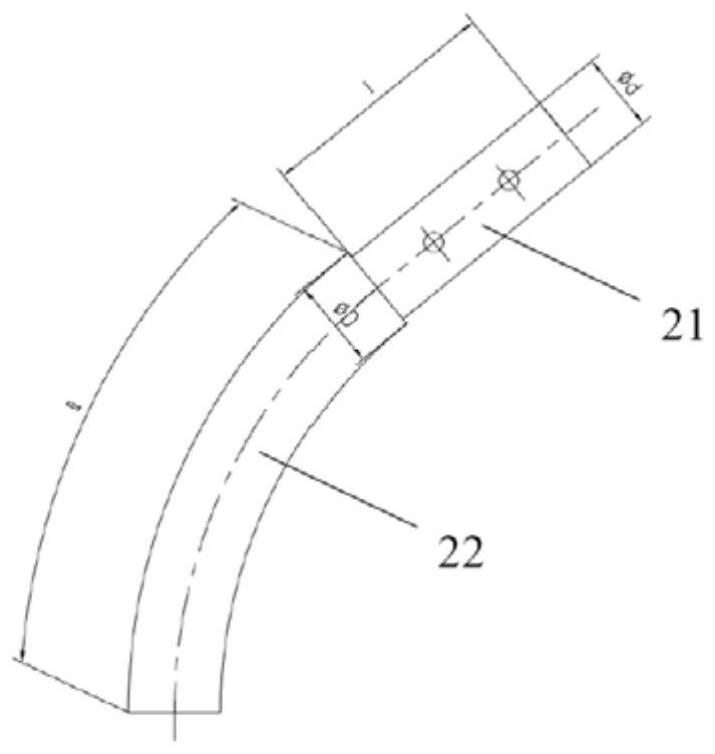

[0029] Such as figure 1 As shown, an insulating pantograph horn includes a metal bow horn main body 1 and a non-metallic bow horn end 2; the metal bow horn main body 1 is connected to the body of the pantograph, and the non-metallic bow horn end 2 and the metal bow horn The main body 1 is fixedly connected; the metal bow horn main body 1 is made of pipe material; specifically, the metal bow horn main body 1 is made of titanium alloy pipe material. While ensuring the strength and hardness, the lightweight design is conducive to the stability of pantograph-catenary flow. The non-metallic bow angle end 2 is made of a solid rod, and the non-metallic bow angle end 2 can be made of non-metallic materials with a certain strength, such as epoxy glass fiber and epoxy resin.

[0030] Here, the outer diameters of the metal bow horn main body 1 and the non-metal bow horn end 2 are the same, which meet normal use requirements.

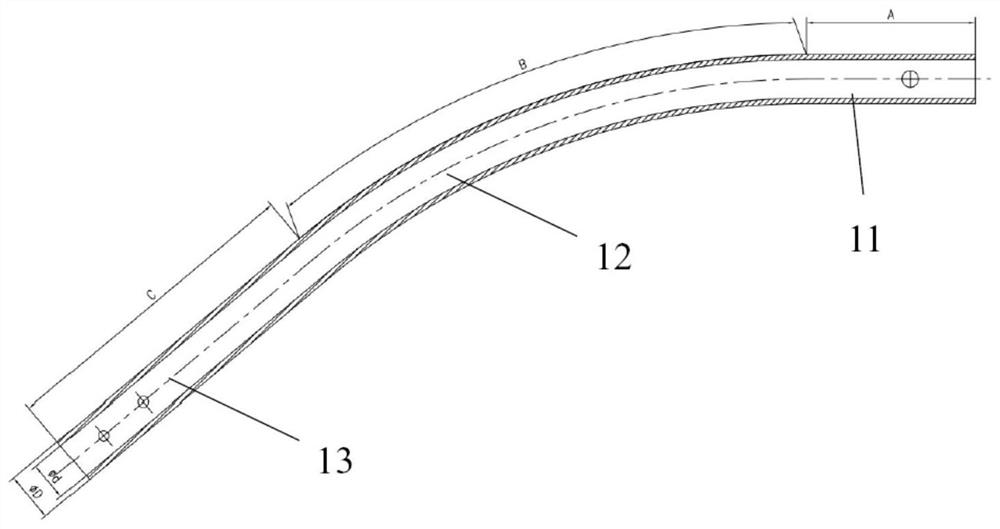

[0031] Such as figure 2 As shown, the metal bow angle mai...

Embodiment 2

[0036] Such as Figure 5 As shown, a pantograph, the two ends of the body of the pantograph are symmetrically provided with the pantograph insulating bow angles described in the first embodiment. Specifically, the pantograph insulation bow angle is connected to the bow head shaft of the pantograph body. In the bow position, the minimum space distance H1 between the pantograph insulation bow angle and the roof should meet the minimum electrical clearance specified in the standard. Requirements; At the same time, after the pantograph insulation bow angle is installed on the pantograph, the bow head height H2 and the bow head length L should meet the vehicle limit requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com