High-efficiency aerator based on pneumatic swirl forced mixing technique and application of high-efficiency aerator

A technology of aerator and cyclone, which is applied in the field of aerator, cyclone mixing, and sewage treatment, can solve the problems of acceleration, etc., and achieve the effect of sufficient mixing, reducing the number of arrangements, and reducing the occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0037] Structures not described in detail in the present invention can be understood as conventional structures in the art.

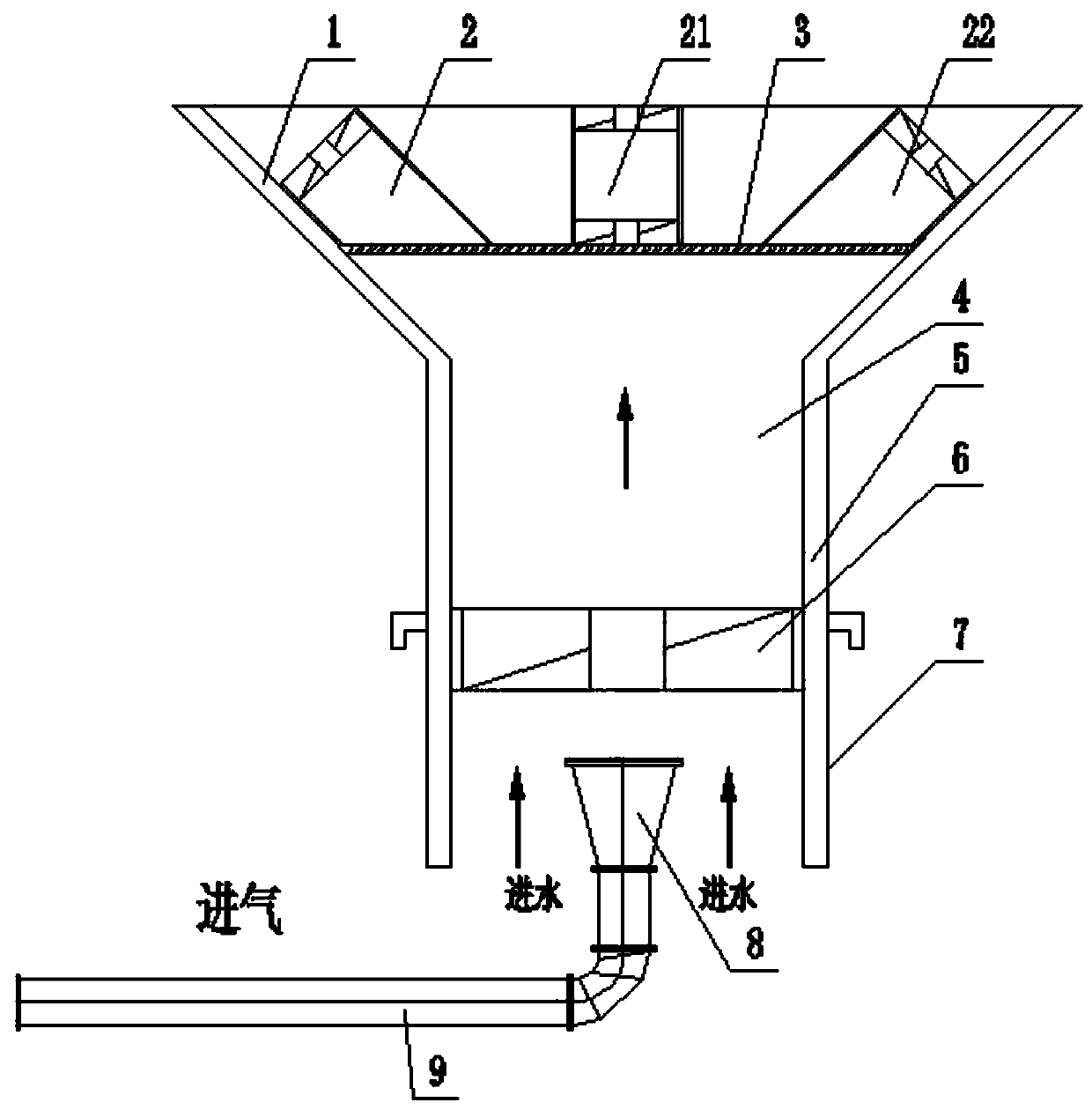

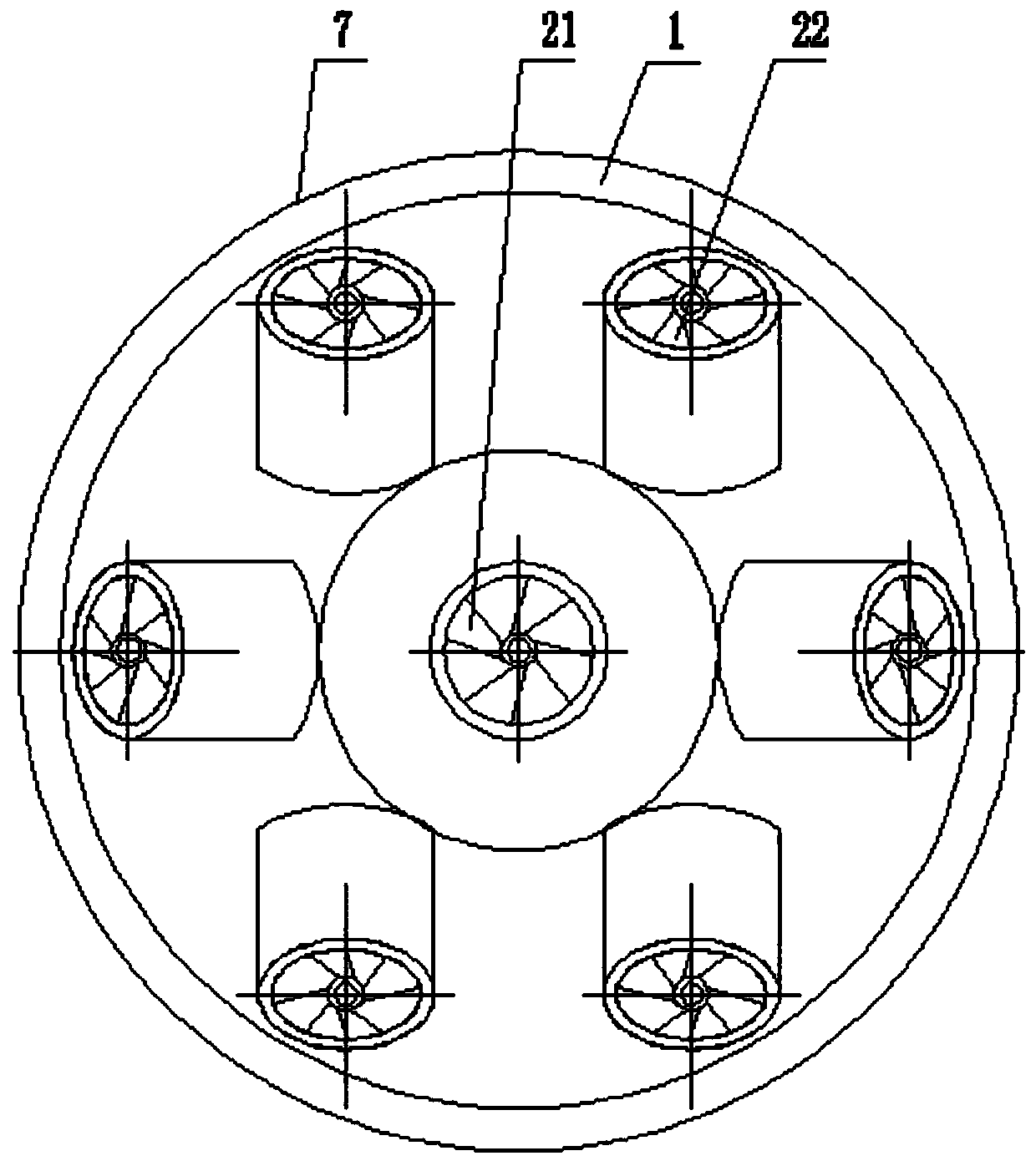

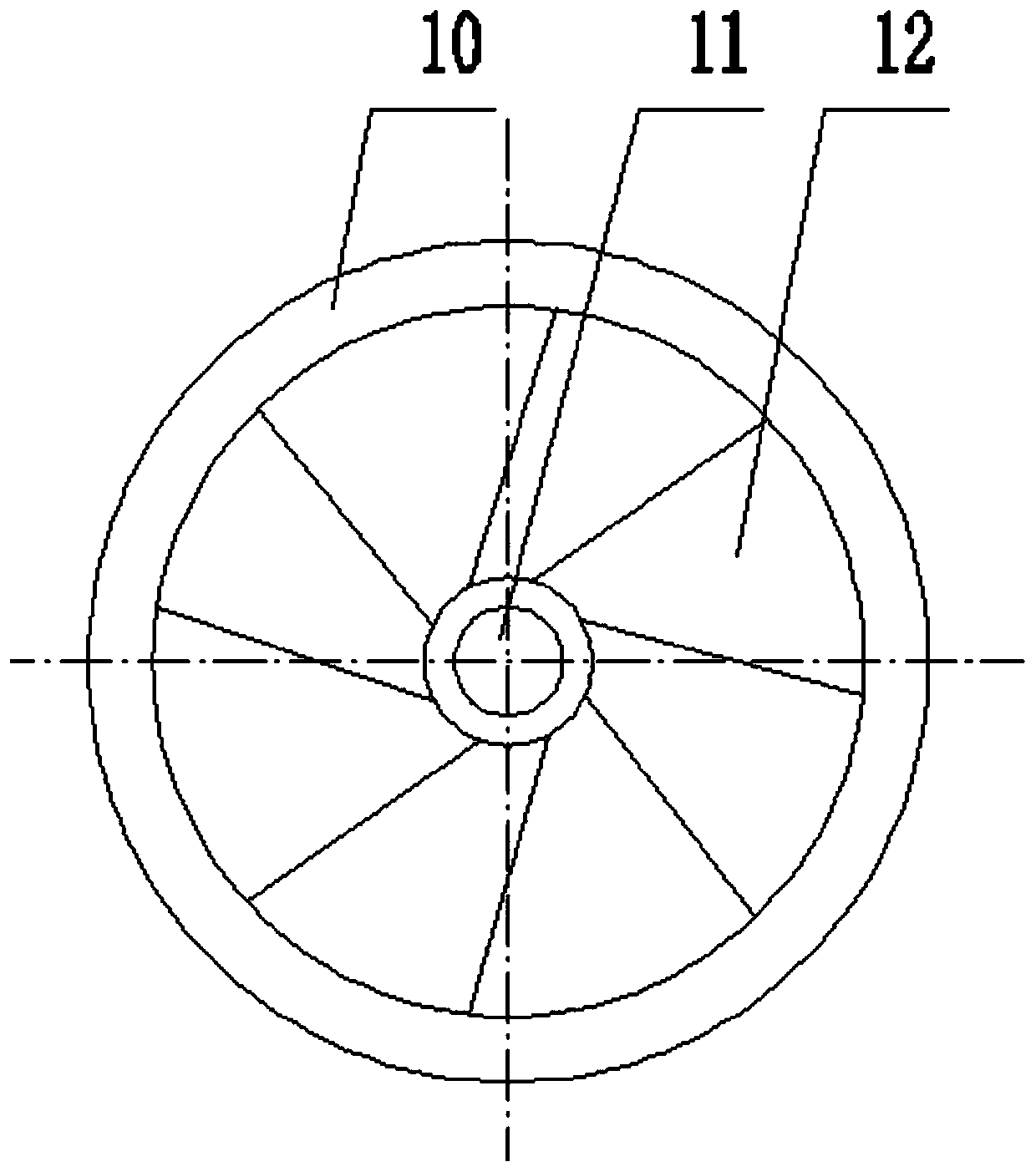

[0038] A high-efficiency aerator based on pneumatic cyclone forced mixing technology, such as figure 1 and figure 2As shown, the aerator includes an aerator housing 7, an air inlet pipe 9, a mixing zone 4 and a cyclone, and the cyclone includes a primary cyclone 6 and a secondary cyclone 2, the Both the mixing zone and the cyclone are arranged in the aerator housing, which is arranged in the vertical direction and has a hollow trumpet-shaped structure with both top and bottom openings. The aerator housing includes The flared end 1 of the horn and the constricted end 5 of the horn are arranged in connection with the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com