Lightweight thermal insulation concrete and preparation method thereof

A thermal insulation concrete, lightweight technology, applied in the field of concrete, can solve problems such as low strength, and achieve the effects of enhancing comprehensive performance, improving thermal insulation performance, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

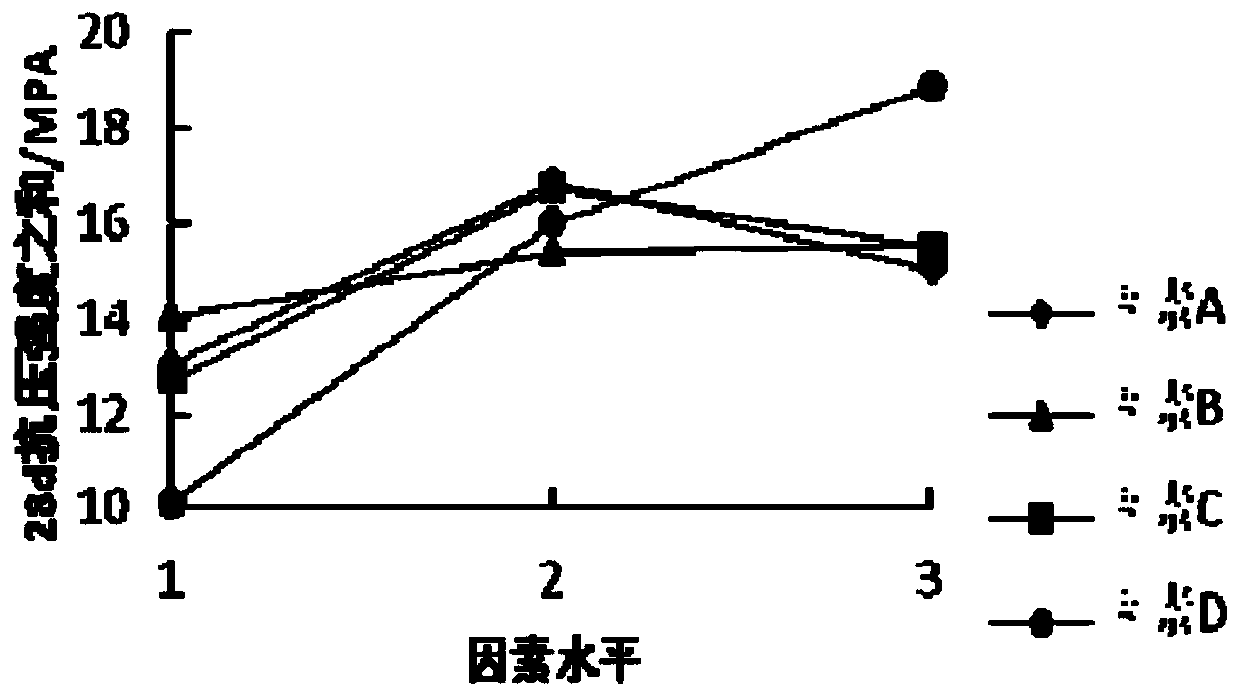

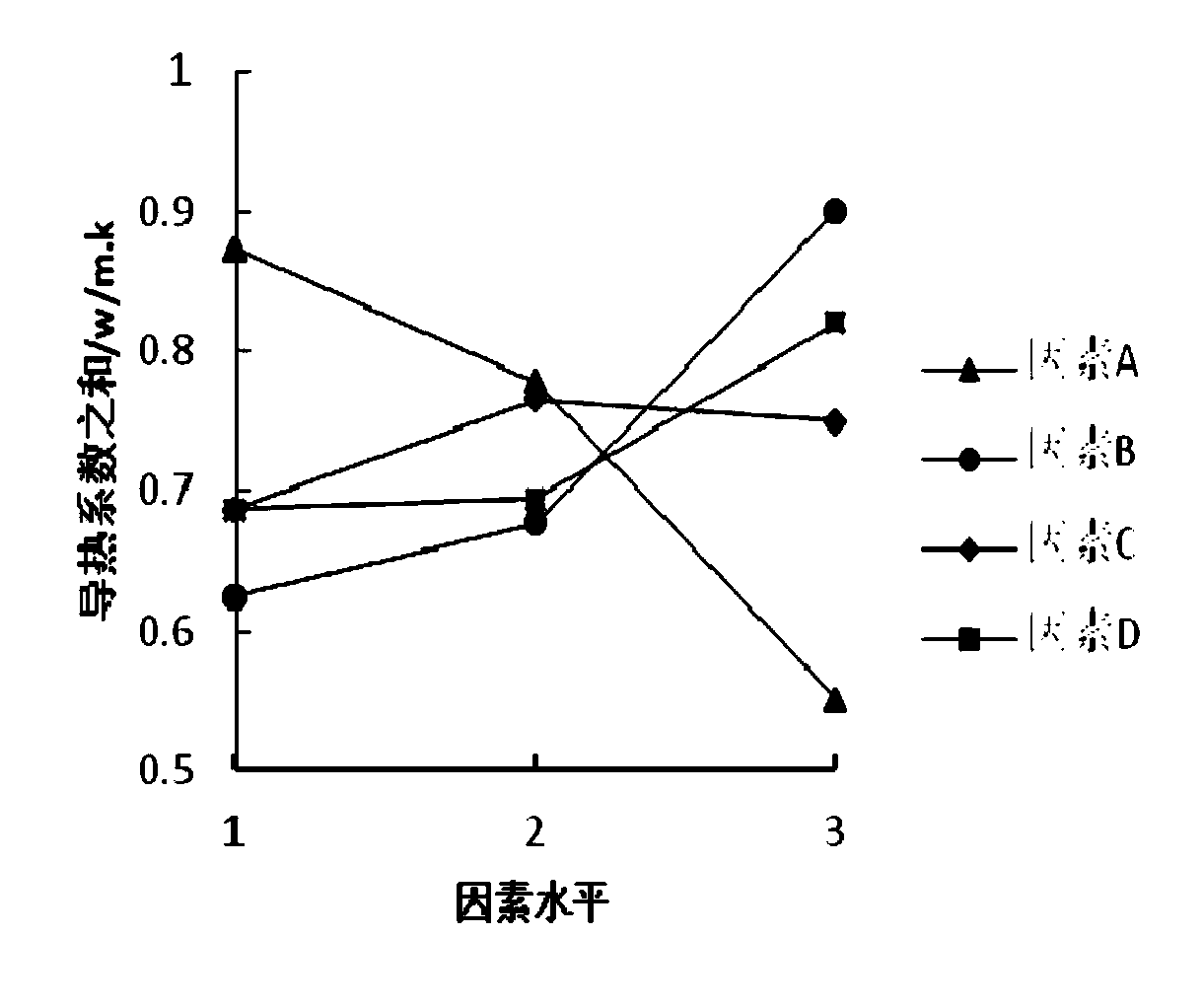

Method used

Image

Examples

Embodiment 1

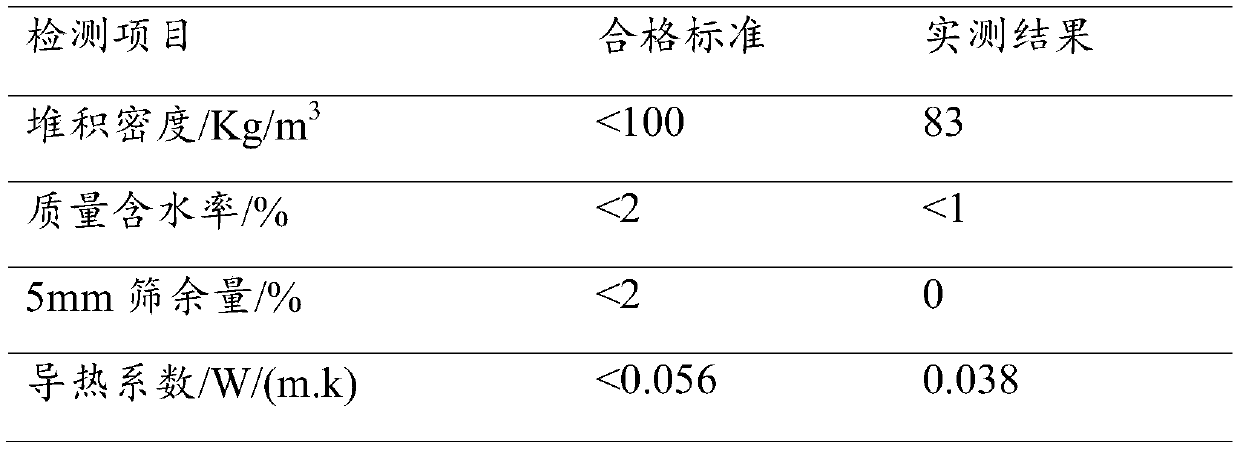

[0019] The light-weight thermal insulation concrete provided in Example 1 has the smallest thermal conductivity and is made of the following raw material components in mass percentages: 40% of cementitious material, 9.0% of expanded pearls, 0% of sand, 9.1% of vitrified microbeads, Hemp fiber 1.5%, superfine mineral powder 13% and water 26.7%.

Embodiment 2

[0021] A light-weight thermal insulation concrete provided in Example 2 has high strength and is made of the following raw material components in mass percentage: 36% of cementitious material, 7% of expanded pearl, 30% of sand, 6% of vitrified microbead, Hemp fiber 1.1%, superfine mineral powder 2% and water 19%.

Embodiment 3

[0023] The light-weight thermal insulation concrete provided in Example 3 is made of the following raw material components in the following mass percentages after weighing the optimal ratio of strength and thermal conductivity: 33% of cementitious material, 8% of expanded pearl, 15% of sand, Vitrified microbeads 6.7%, hemp fiber 1.3%, ultrafine mineral powder 11% and water 22%.

[0024] The preparation method of the lightweight thermal insulation concrete of embodiment 1-3 is all as follows:

[0025] 1) Prepare each raw material component according to the mass percentage ratio:

[0026] 2) Weigh the expanded perlite and vitrified microspheres according to the proportion and pour them into the mixing tank and stir for 15S. After mixing evenly, add additional water and stir for 15S, then add the uniformly mixed cementitious material and stir for 15S to let the light aggregate The cementitious material is evenly attached to the surface; the additional water consumption is obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com