Yarn containing photocatalyst and preparation method thereof

A technology of photocatalyst and yarn, which is applied in the direction of yarn, textiles and papermaking, etc. It can solve the problems affecting the color of yarn, achieve good application and market prospects, reduce costs and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

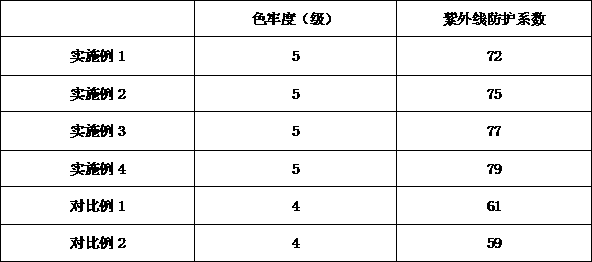

Examples

Embodiment 1

[0023] A color spinning loaded photocatalyst yarn is made by blending 15-35 parts by weight of white fibers, 20-40 parts by weight of light gray fibers and 20-45 parts by weight of blue fibers;

[0024] Using cotton fiber as raw material;

[0025] Photocatalyst dispersion liquid: the average particle size of nano titanium dioxide is 180nm, the molecular weight of degraded chitosan is 3000, the mass ratio of the two is 5:1, and water is used as solvent to prepare dispersion liquid with titanium dioxide concentration of 2 g / L and 3 g / L ;

[0026] Fiber dyeing: Divide the pretreated cotton fiber into three parts at a ratio of 25:30:45, add them to white, light gray, and blue dye solutions respectively, dye at 55°C for 30 minutes, then cool to room temperature and adjust with acetic acid. After the pH is 6.8, it is washed with water, then oiled, dehydrated and dried to obtain three kinds of fibers with different color shades, namely white dyed fiber, light gray dyed fiber and blu...

Embodiment 2

[0030] A color spinning loaded photocatalyst yarn is made by blending 20 parts by weight of white fibers, 40 parts by weight of light gray fibers and 40 parts by weight of blue fibers;

[0031] Use polyester fiber as raw material;

[0032] Photocatalyst dispersion liquid: the average particle size of nano titanium dioxide is 180nm, the molecular weight of degraded chitosan is 3000, the mass ratio of the two is 5:1, and water is used as solvent to prepare dispersion liquid with titanium dioxide concentration of 5 g / L and 7 g / L ;

[0033] Fiber dyeing: Divide the pretreated polyester fiber into three parts at a ratio of 20:40:40, add them to white, light gray and blue dye solutions respectively, dye at 40°C for 60 min, then cool to room temperature, and use acetic acid. After adjusting the pH to 6.8, it is washed with water, then oiled, dehydrated and dried to obtain three kinds of fibers with different color shades, namely white dyed fiber, light gray dyed fiber and blue dyed ...

Embodiment 3

[0037] A color spinning loaded photocatalyst yarn is made by blending 35 parts by weight of white fibers, 40 parts by weight of light pink fibers and 25 parts by weight of yellow fibers;

[0038] Using cotton fiber as raw material;

[0039] Photocatalyst dispersion liquid: the average particle size of nano titanium dioxide is 180nm, the molecular weight of degraded chitosan is 3000, the mass ratio of the two is 5:1, and water is used as solvent to prepare dispersion liquid with titanium dioxide concentration of 7 g / L and 8 g / L ;

[0040] Fiber dyeing: Divide the pretreated cotton fiber into three parts according to 35:40:25, add them to the white, light pink and yellow dye solutions respectively, dye at 45°C for 50 min, then cool to room temperature and adjust the pH with acetic acid Washing with water after 6.5, then oiling, dehydrating and drying to obtain three kinds of fibers with different color shades, namely white fibers, light pink fibers and yellow fibers;

[0041] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com