A twist-resistant high-pressure delivery pipeline applied to hydraulic systems

A high-pressure conveying pipe and hydraulic system technology, applied in the direction of hoses, pipes, pipes/pipe joints/fittings, etc., can solve the problems of unreasonable installation of hoses, high temperature of oil use, damage of high-pressure hoses, etc., and reduce processing time. The effect of labor amount, material saving, good anti-torsion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

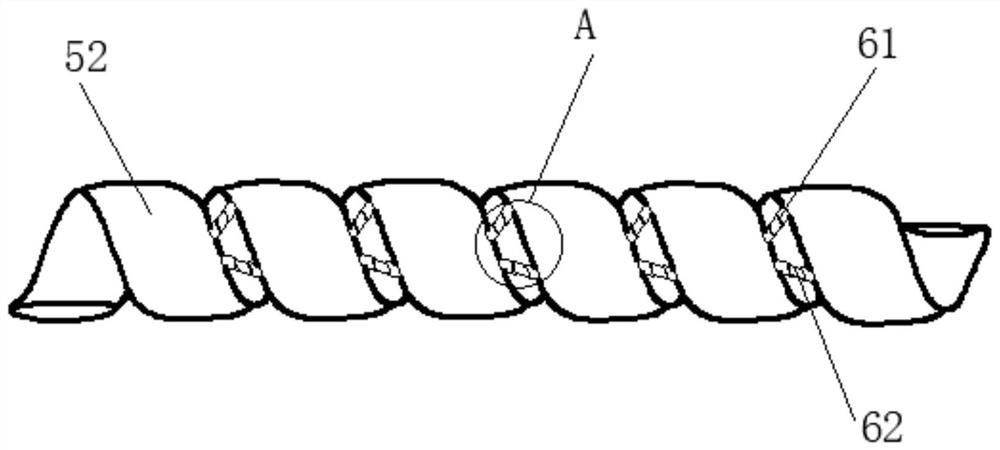

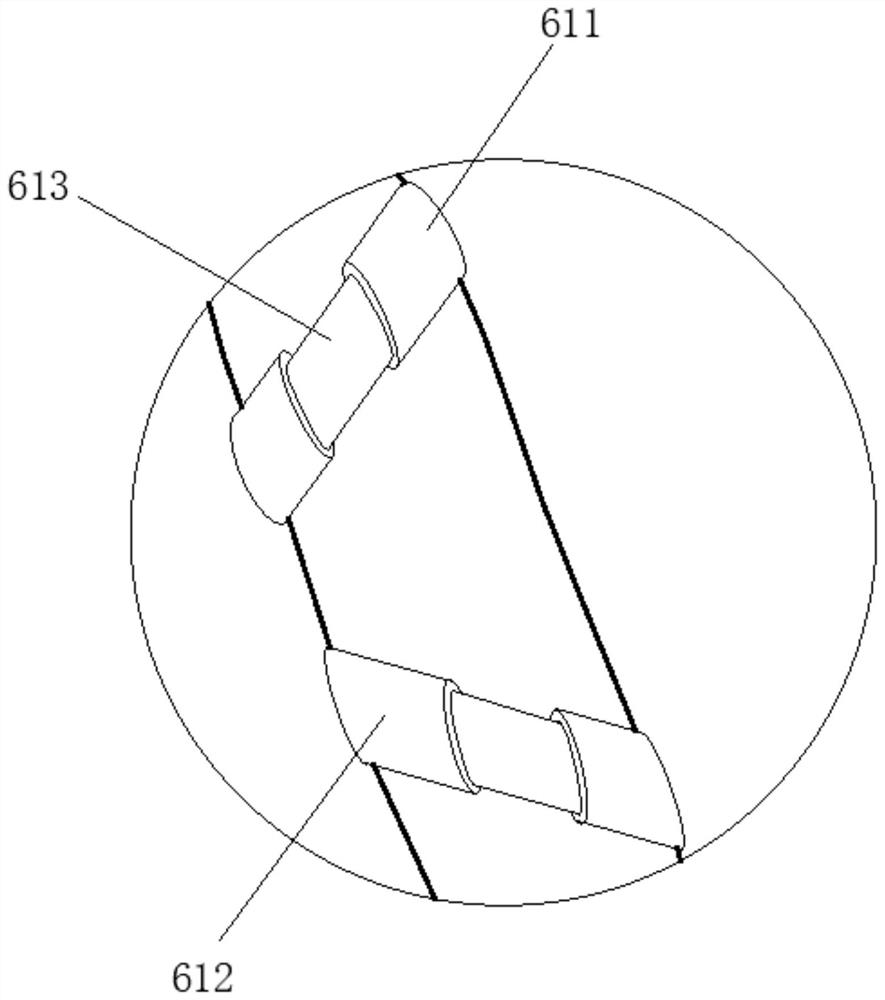

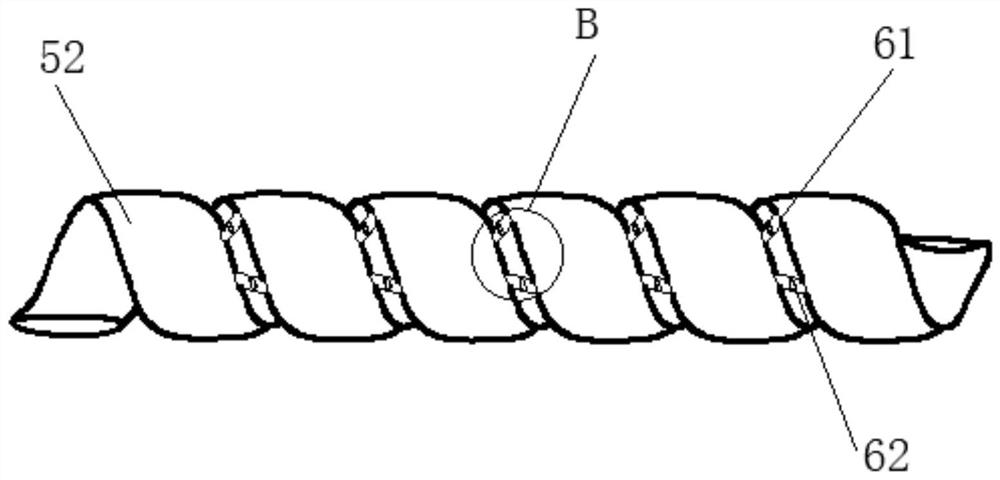

[0048] see Figure 11 with Figure 12 , a torsion-resistant high-pressure delivery pipeline used in hydraulic systems, including a high-pressure hose body 1 that is sequentially arranged as an inner rubber layer 4, a reinforcement layer 5, a middle rubber layer 3, and an outer rubber layer 2 from the inside to the outside. refer to figure 1 with Figure 10 The reinforcement layer 5 includes a common spiral wrap 51 and a bidirectional anti-twist spiral wrap 52, the bidirectional anti-twist spiral wrap 52 is helical, and a pair of bidirectional anti-twist units are arranged at the helical gap of the bidirectional anti-twist spiral wrap 52, see figure 1 , the two-way anti-twist unit includes a forward twist extrusion unit 61 and a reverse twist extrusion unit 62, the forward twist extrusion unit 61 is located on the upper side of the reverse twist extrusion unit 62, and it sets the reinforcement layer 5 of the high-pressure hose Two-layer spiral wrapping, and a two-way anti-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com