Method for testing oxygen mass transfer resistance of ordered electrodes

A technology of mass transfer resistance and testing method, which is applied to circuits, fuel cells, electrical components, etc., and can solve problems such as high cost and insufficient service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Ordered electrode preparation: sputtering 0.04mg / cm on GDL using magnetron sputtering technology 2 Pt, prepare ordered electrodes, and use them as cathode electrodes to make MEA; figure 1 It is the SEM image of the ordered electrode of the present invention, from which the stripes of the ordered texture structure can be seen, and the tested Pt loading is 0.04mg / cm 2 , is a low-platinum ordered electrode;

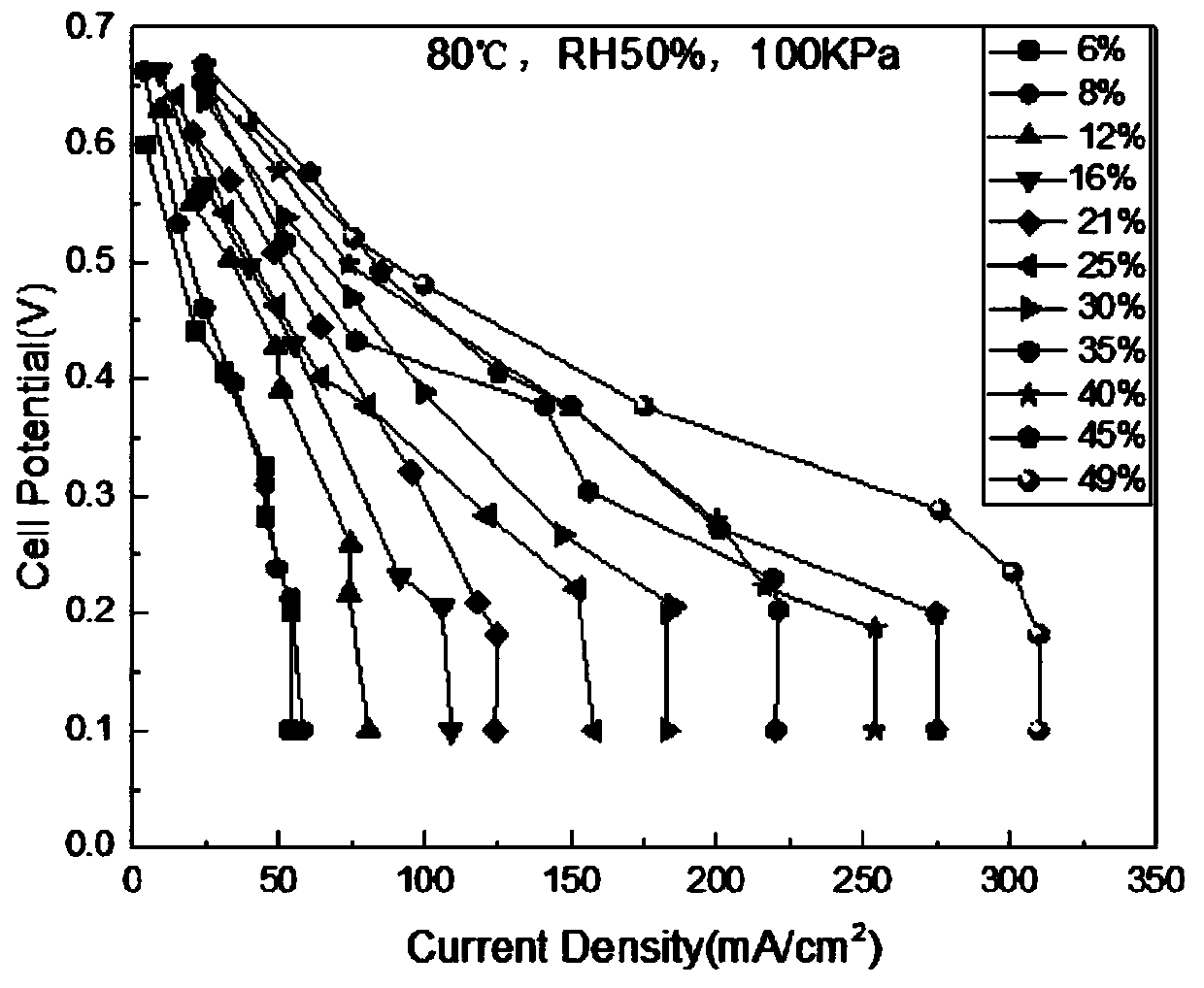

[0032] Limiting current density test: the assembly compression rate of a single cell is 20%, the battery operating temperature is 80°C, the air flow is 1.6L / min for the anode, 2.0L / min for the cathode, 50% humidity for the cathode and anode, and 100KPa for the back pressure. Adjust the cathode The side oxygen concentration is 6%, the mixed gas is oxygen and nitrogen, start to test the limit current density, increase the current slowly, and the voltage starts to drop. When the voltage drops to 0.2V, the voltage is difficult to stabilize at this time and drops to zero....

Embodiment 2

[0038] Ordered electrode preparation: sputtering 0.04mg / cm on GDL using magnetron sputtering technology 2 Pt, and use it as cathode electrode to make MEA

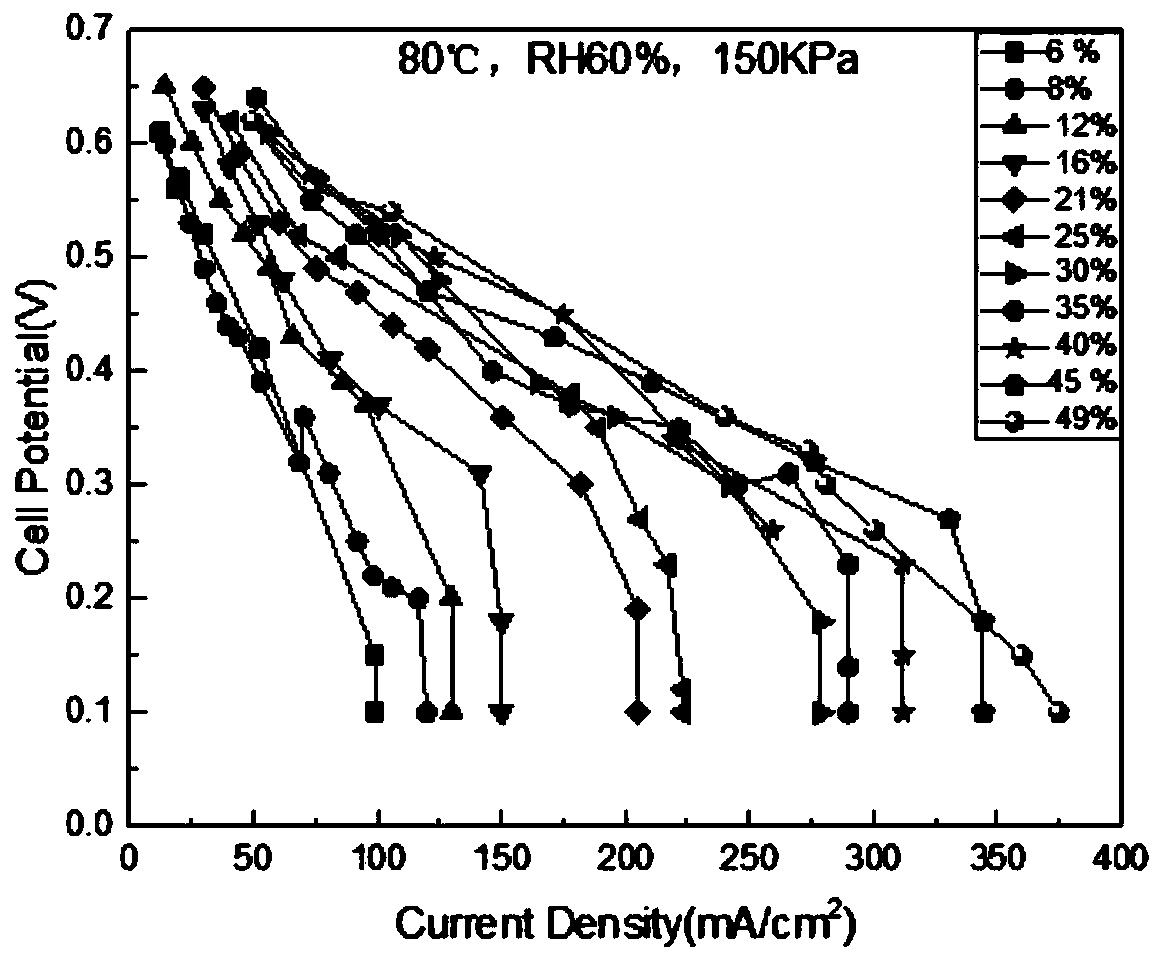

[0039]Limiting current test: The compression rate of single cell assembly is 15%, the operating temperature of the battery is 80°C, the air flow is 1.6L / min for the anode, 2.0L / min for the cathode, 60% humidity for the cathode and anode, and 150KPa for the back pressure. Adjust the cathode side The oxygen concentration is 6%, the mixed gas is oxygen and nitrogen, start to test the limit current density, slowly increase the current, the voltage starts to drop, when the voltage drops to 0.2V, the voltage is difficult to stabilize at this time, and drops to zero, record the current The current density is the limiting current density. Stop the test, and after a period of purging with nitrogen, continue to increase the cathode oxygen concentration to 8%, and continue to test the limiting current density in this way until the ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compression ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com