Polymer composition containing modified chlorinated polyolefin and method for producing same

A technology for chlorinating polyolefins and compounds, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of insufficient curing and insufficient manufacturing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

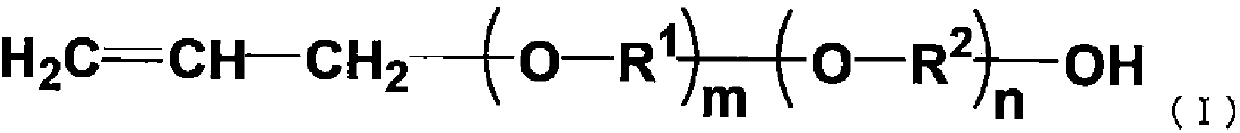

[0091]In a four-necked bottle with a cooling tube, 100 parts of "Superclon 822S" (trade name, produced by Nippon Paper Co., Ltd., maleic anhydride-modified chlorinated polyolefin, 24.5% chlorine content) and 221 parts of toluene were charged. 1. 0.05 parts of di-tert-butylhydroxytoluene (abbreviation: BHT), stirred while blowing air into the liquid phase, and raised the temperature to about 95° C. to prepare a solution. 57.5 parts of 2-allyloxyethanol and 0.1 part of tetrabutylammonium bromide were added thereto, and stirring was continued while making 2-allyloxyethanol and an acid anhydride group react. In the infrared absorption analysis of the solid components in the solution, at about 1770cm -1 The absorbance of about 1460cm -1 In the stage where the absorbance ratio does not change substantially, the temperature is lowered to about 90°C, and the compound (a) containing allyloxy and hydroxyl groups, namely about 55 parts of 2-allyloxyethanol, and having allyloxyl groups i...

Embodiment 2

[0093] In a four-necked bottle with a cooling tube, 100 parts of "Superclon 822S" (trade name, produced by Nippon Paper Co., Ltd., maleic anhydride-modified chlorinated polyolefin, chlorine content 24.5%) and 70 parts of toluene were charged. 1. 0.05 parts of di-tert-butylhydroxytoluene (abbreviation: BHT), stirred while blowing air into the liquid phase, and raised the temperature to about 95° C. to prepare a solution. 23 parts of 2-allyloxyethanol and 0.1 part of tetrabutylammonium bromide were added thereto, and stirring was continued while making 2-allyloxyethanol and an acid anhydride group react. In the infrared absorption analysis of the solid components in the solution, at about 1770cm -1 The absorbance of about 1460cm -1 At the stage where the absorbance ratio does not change substantially, the temperature is lowered to about 90°C, and 150 parts of toluene and 34.5 parts of 2-allyloxyethanol are further added to obtain a compound (a) containing an allyloxy group and ...

Embodiment 3

[0095] In a four-necked bottle with a cooling tube, 100 parts of "Superclon 3228S" (trade name, manufactured by Nippon Paper Co., Ltd., maleic anhydride-modified chlorinated polyolefin, 28% chlorine content) and 210 parts of toluene were charged. , 11 parts of butyl acetate, and 0.05 part of di-tert-butylhydroxytoluene (abbreviation: BHT), stirred while blowing air into the liquid phase, and raised the temperature to about 95° C. to prepare a solution. 57.5 parts of 2-allyloxyethanol and 0.1 part of tetrabutylammonium bromide were added thereto, and stirring was continued while making 2-allyloxyethanol and an acid anhydride group react. In the infrared absorption analysis of the solid components in the solution, at about 1770cm -1 The absorbance of about 1460cm -1 In the stage where the absorbance ratio does not change substantially, the temperature is lowered to about 90°C, and the compound (a) containing allyloxy and hydroxyl groups, namely about 55 parts of 2-allyloxyethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com