Self-propelled straw-picking and feed-baling machine

A feed bundling and self-propelled technology, which is applied in the field of agricultural machinery, can solve the problems of poor straw crushing and rubbing effect, large soil content of straw, and animals that do not like to eat it, so as to achieve convenient and flexible operation, low fuel consumption, and economical transportation. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

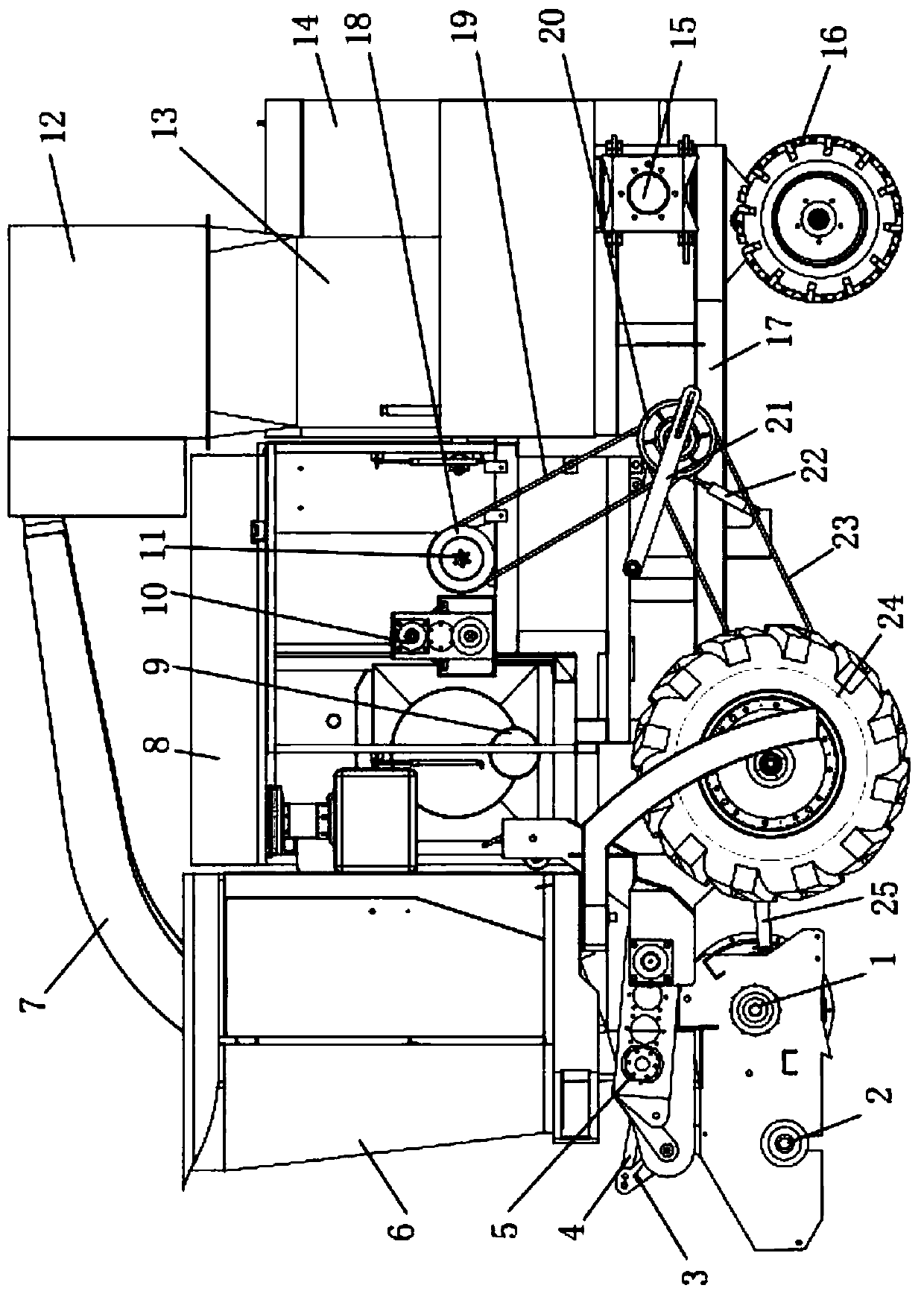

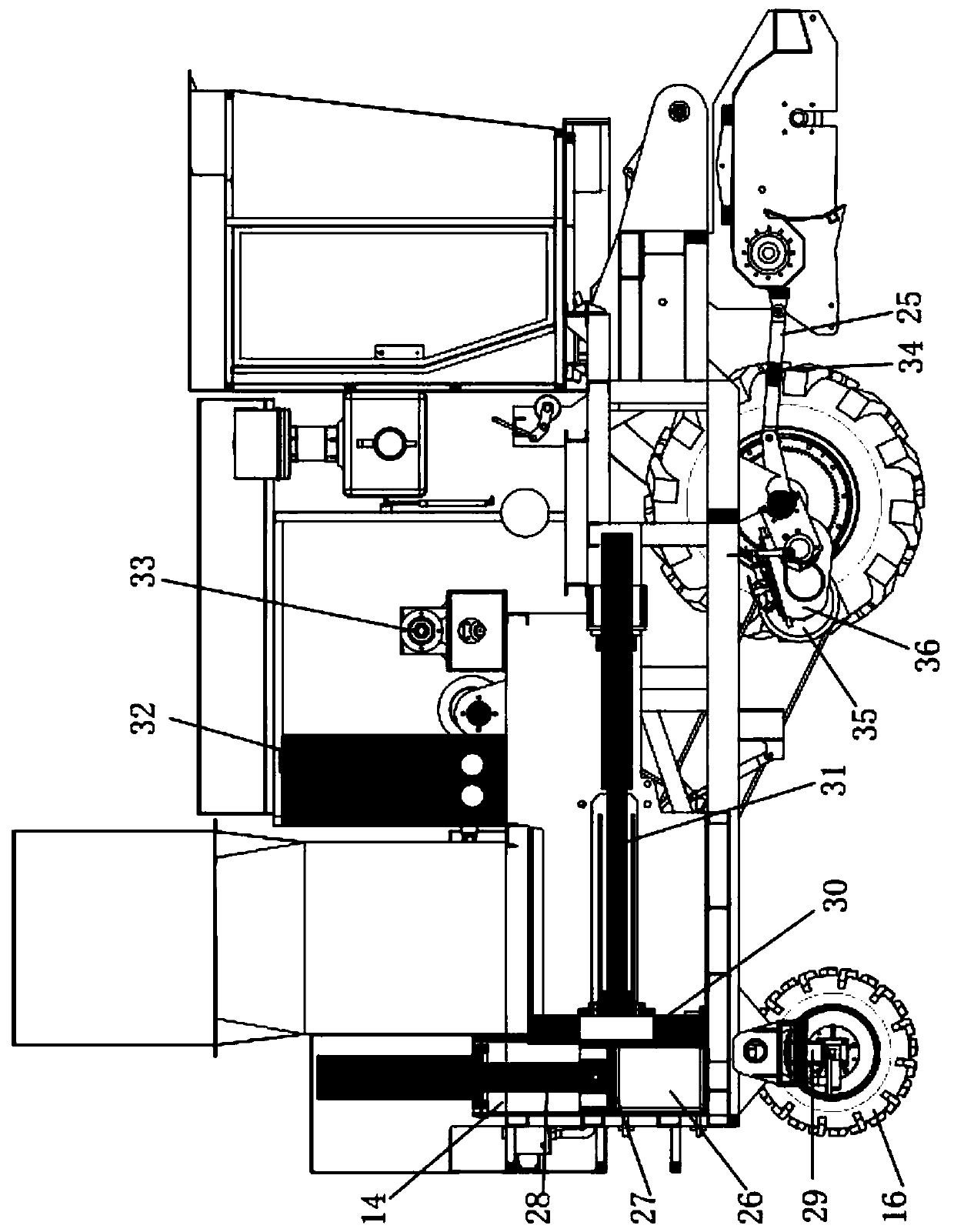

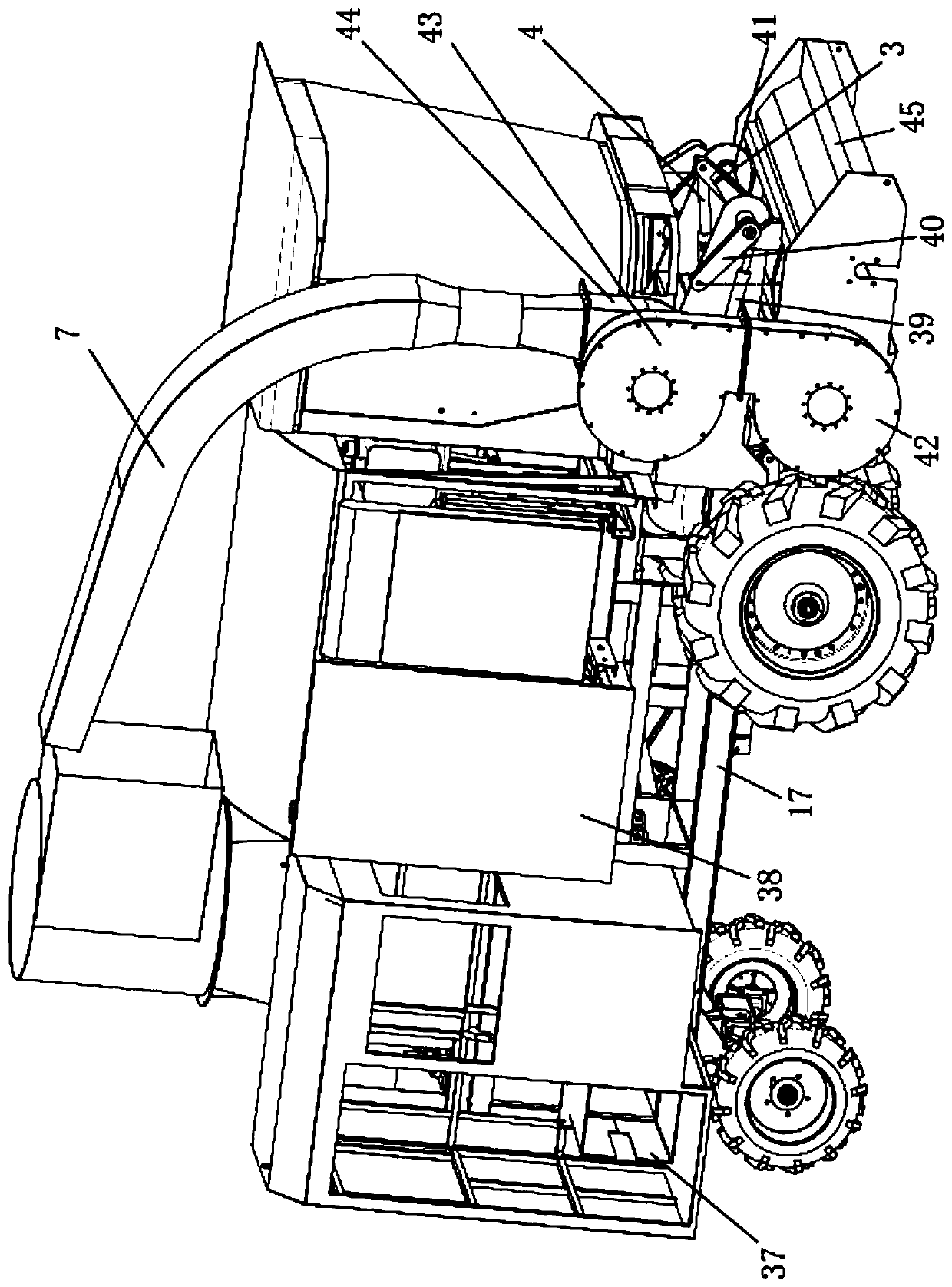

[0037] Such as Figure 1-Figure 10 As shown, the self-propelled straw picking feed bundling machine includes a motor vehicle body 17 with a walking wheel set, a driver's cab 6 located on the motor vehicle body 17, a picking system, a bundling system and a transmission system.

[0038] Wherein, the walking wheel set is made up of a pair of walking front wheels 24 and a pair of turning rear wheels 16 . Described steering rear wheel 16 utilizes steering rear axle 29 to be installed on the motor vehicle body 17, and the diameter of steering rear wheel 16 is less than the diameter of walking front wheel 24.

[0039] Described pick-up system is by the pick-up cover 45 that is fixed on motor vehicle body 17 front ends, the pick-up device 2 that is supported in the front part of pick-up cover 45, the transmission auger 1 that is supported in the rear part of pick-up cover 45, is located at transmission auger 1. The secondary kneading and pulverizing device 43 above the end is compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com