Double-sided black polyester sound-absorbing cotton

A sound-absorbing cotton, black technology, applied in the field of sound-absorbing materials, can solve the problems of PET/PP two-component sound-absorbing cotton corner waste recycling, poor oxidation resistance and elasticity of products, difficult to achieve blending, etc., to achieve strong decoration , easy processing, and the effect of improving the support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

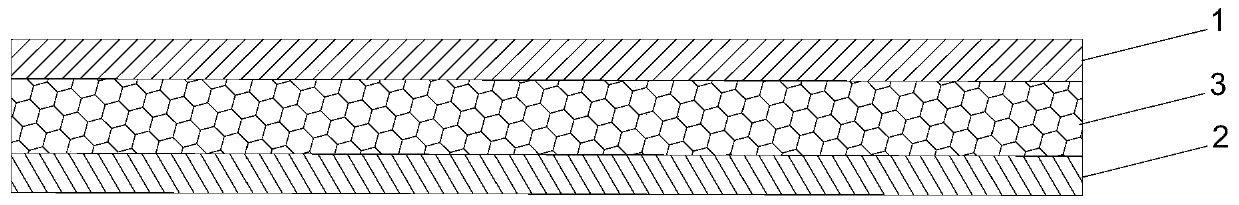

[0042] Example 4 is a comparative example of Example 2. The difference between this Example 4 and Example 2 is that the fineness of the PET polyester fiber used in the sound-absorbing cotton layer 3 is 0.5D, and other components are consistent with Example 2. The double-sided black polyester sound-absorbing cotton in Example 4 includes: the first non-woven fabric layer 1, the second non-woven fabric layer 2 and the sound-absorbing cotton layer 3, the upper surface of the sound-absorbing cotton layer 3 and the first non-woven fabric layer The lower surface of the layer 1 is attached, and the lower surface of the sound-absorbing cotton layer 3 is attached to the lower surface of the second non-woven fabric layer 2 . The first non-woven fabric layer 1 includes the following components by weight: 98 parts of PET polyester fiber, 1.5 parts of carbon black, and 0.5 parts of carbon black dispersant. The second non-woven fabric layer 2 includes the following components by weight: 98 p...

Embodiment 5

[0043] Example 5 is a comparative example of Example 2. The difference between this Example 5 and Example 2 is that the fineness of the PET polyester fiber used in the sound-absorbing cotton layer 3 is 1.0D, and other components are consistent with Example 2. The double-sided black polyester sound-absorbing cotton in Example 5 includes: the first non-woven fabric layer 1, the second non-woven fabric layer 2 and the sound-absorbing cotton layer 3, the upper surface of the sound-absorbing cotton layer 3 and the first non-woven fabric layer The lower surface of the layer 1 is attached, and the lower surface of the sound-absorbing cotton layer 3 is attached to the lower surface of the second non-woven fabric layer 2 . The first non-woven fabric layer 1 includes the following components by weight: 98 parts of PET polyester fiber, 1.5 parts of carbon black, and 0.5 parts of carbon black dispersant. The second non-woven fabric layer 2 includes the following components by weight: 98 p...

Embodiment 6

[0044] Embodiment 6 is a comparative example of Embodiment 2. The difference between this Embodiment 6 and Embodiment 2 is that the flow resistance of the PET polyester fiber used in the first non-woven fabric layer 1 is 2 million Pa.s / ㎡, and the second The PET polyester fiber used in the non-woven fabric layer 2 has a flow resistance of 2 million Pa.s / ㎡, and other components are consistent with the second embodiment. The double-sided black polyester sound-absorbing cotton in Example 6 includes: the first non-woven fabric layer 1, the second non-woven fabric layer 2 and the sound-absorbing cotton layer 3, the upper surface of the sound-absorbing cotton layer 3 and the first non-woven fabric layer The lower surface of the layer 1 is attached, and the lower surface of the sound-absorbing cotton layer 3 is attached to the lower surface of the second non-woven fabric layer 2 . The first non-woven fabric layer 1 includes the following components by weight: 98 parts of PET polyester...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com