Narrow-gap welding gun and preparation method thereof

A narrow gap and welding torch technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as poor quality of welded joints, achieve the effect of reducing manufacturing costs and improving protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

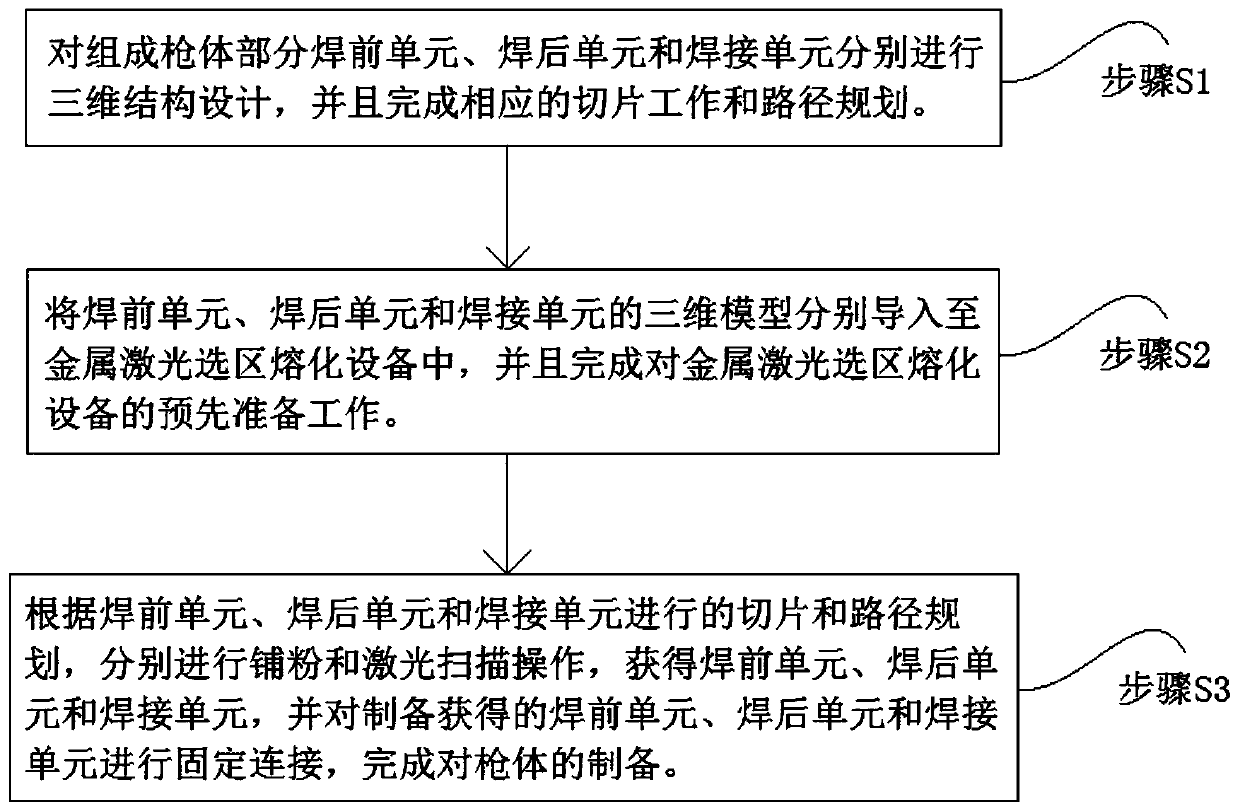

[0037] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

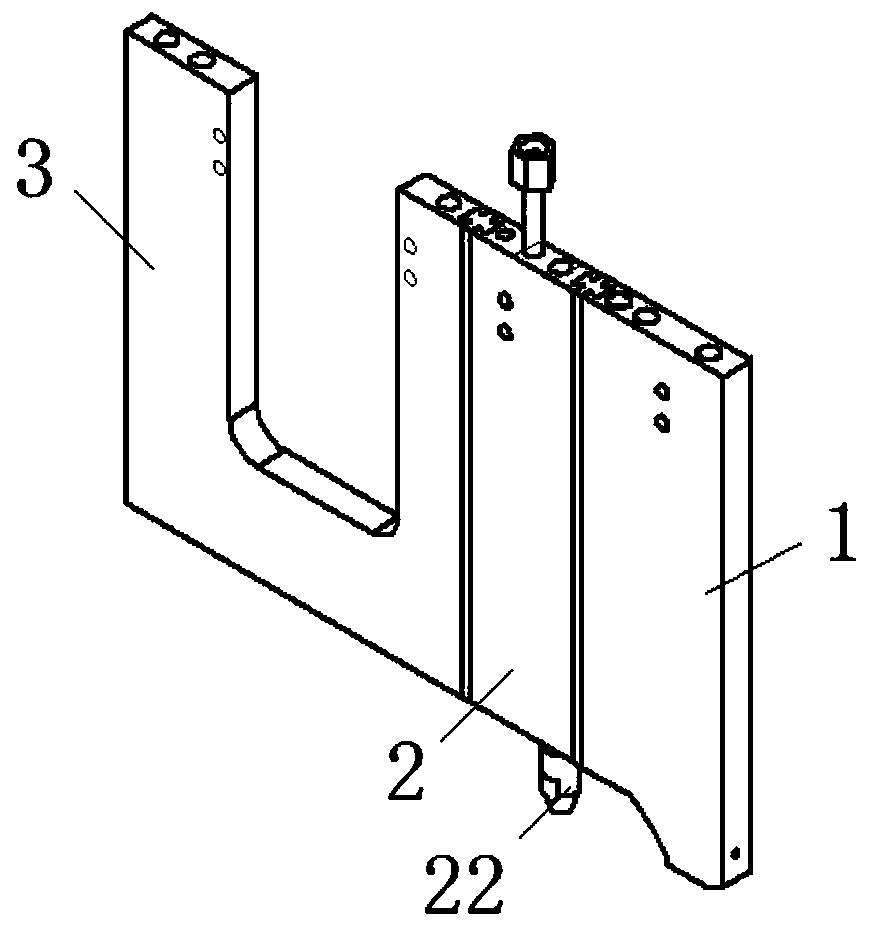

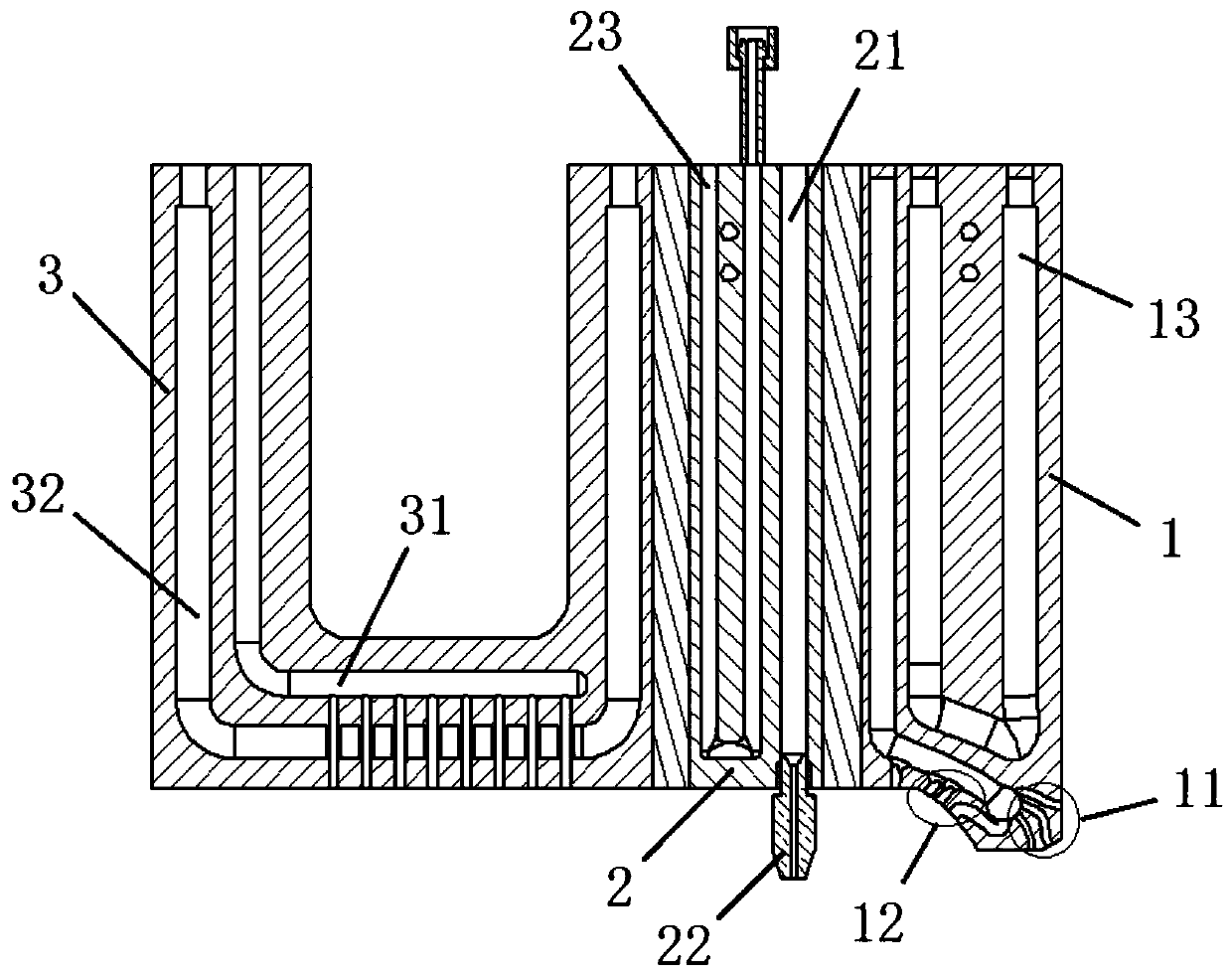

[0038] combine figure 1 and figure 2 As shown, the narrow-gap welding torch of this embodiment includes a flat-shaped torch body, and the torch body includes a pre-welding unit 1 , a welding unit 2 and a post-welding unit 3 sequentially distributed along the welding direction.

[0039] The pre-welding unit 1 is provided with a first shielding gas channel 11 and a second shielding gas channel 12 for simultaneously introducing pre-weld shielding gas. Wherein, in this embodiment, a common input part is used to introduce the shielding gas before welding, while the first shielding gas passage 11 and the second shielding gas passage 12 are directly used as two output parts of the shielding gas before welding, thus The repeated setting of the same gas channel in the pre-welding unit can be reduced, and the structural design of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com