Automatic intubating machine

An intubation machine and automatic technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low intubation efficiency, difficulty in handling, and non-rebound connection tubes, so as to ensure the movement track and improve the intubation. Good pipe efficiency and guiding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

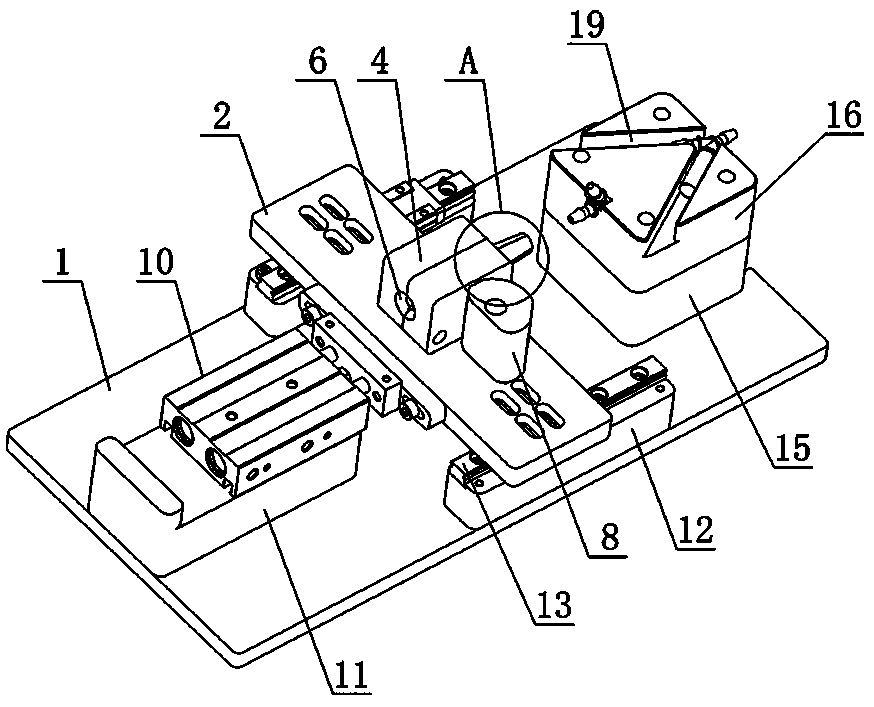

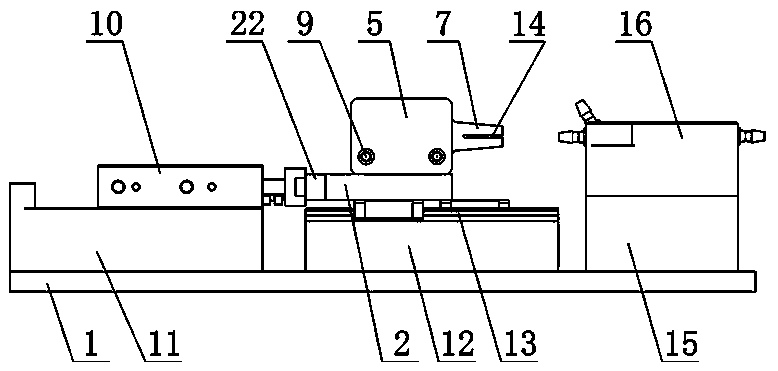

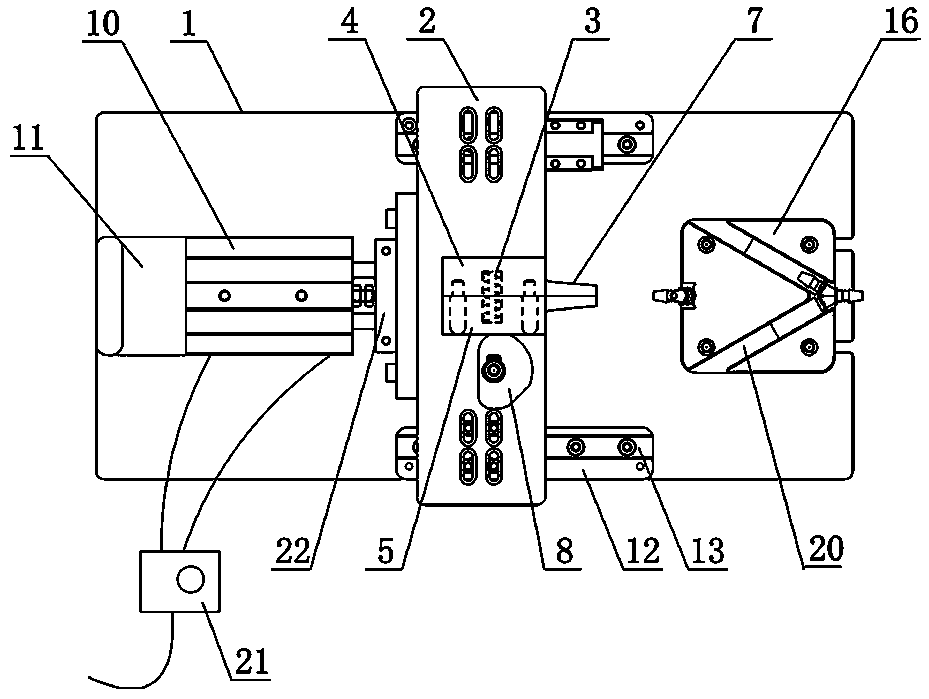

[0023] Such as Figure 1-3 As shown, the automatic intubation machine of the present invention includes a base 1 on which a power source, a clamping assembly and a joint fixing assembly for fixing the connecting pipe are arranged at intervals from left to right, and the power source is a parallel bar cylinder 10 (Of course, other linear drive power sources can also be used, such as hydraulic cylinders, electric push rods, etc.), the double-rod cylinder 10 is fixedly installed on the base 1 through the height block 11; The A port and B port of the valve 21 (4H210-08) are connected, and the P port of the lever valve is connected with the air source. The extension or retraction of the piston rod of the double-rod cylinder 10 is controlled by the lever valve 21 to realize the clamping assembly. Fast back and forth translation left and right;

[0024] Such as Figure 1-3 As shown, the base 1 is provided with a guide assembly, and the guide assembly includes a pair of guide blocks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com