System for recovering ammonium sulfate and recycling organic matters from evaporation concentrated solution of acrylonitrile dilute ammonium sulfate solution and application method thereof

A technology for evaporating concentrated liquid and ammonium sulfate, applied in ammonium sulfate and other directions, can solve the problems of high cost, high cost of flue gas desulfurization and denitrification, flue gas emission, etc., and achieve the effect of reducing adsorption and coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

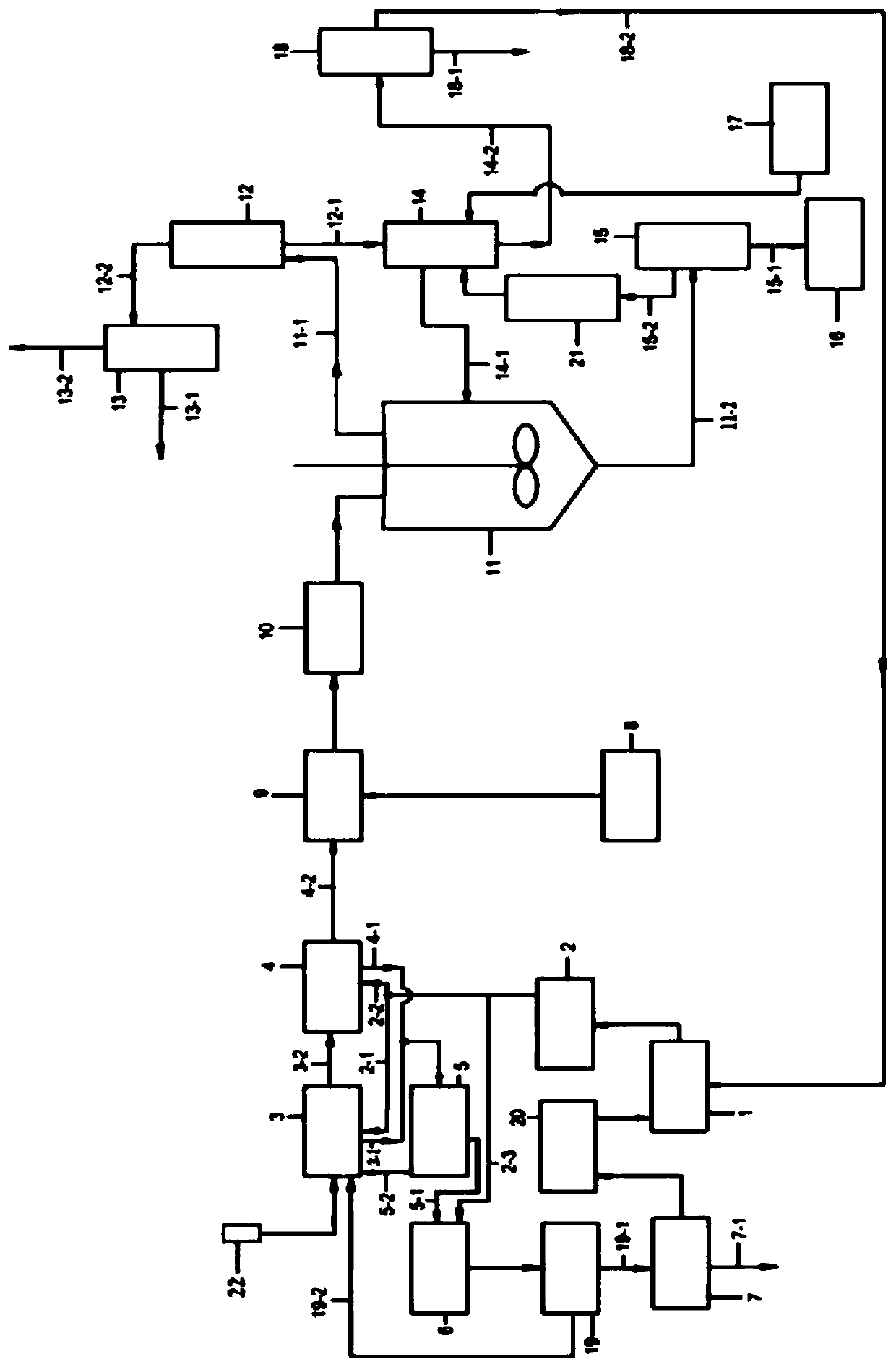

[0035] Specific implementation mode one: this implementation mode is a system for ammonium sulfate recovery and organic resource utilization in the evaporation concentrate of acrylonitrile dilute ammonium sulfate liquid, such as Figure 1-Figure 2 As shown, it is specifically composed of extractant storage tank 1, heat exchanger 2, first crystallizer 3, second crystallizer 4, first solid-liquid separation device 5, scrubber 6, drying device 7, modifier storage tank 8. Liquid-liquid mixer 9, pre-reactor 10, post-reactor 11, first condenser 12, gas absorption device 13, liquid-liquid separator 14, evaporator 15, product storage tank 16, water agent storage tank 17 , a rectifying tower 18, a second solid-liquid separation device 19, a second condenser 20, a third condenser 21 and a plurality of pipeline combinations;

[0036] The first crystallizer 3 is a cooling crystallizer; the second crystallizer 4 is a cooling crystallizer;

[0037] Described scrubber 6 has agitator;

[00...

specific Embodiment approach 2

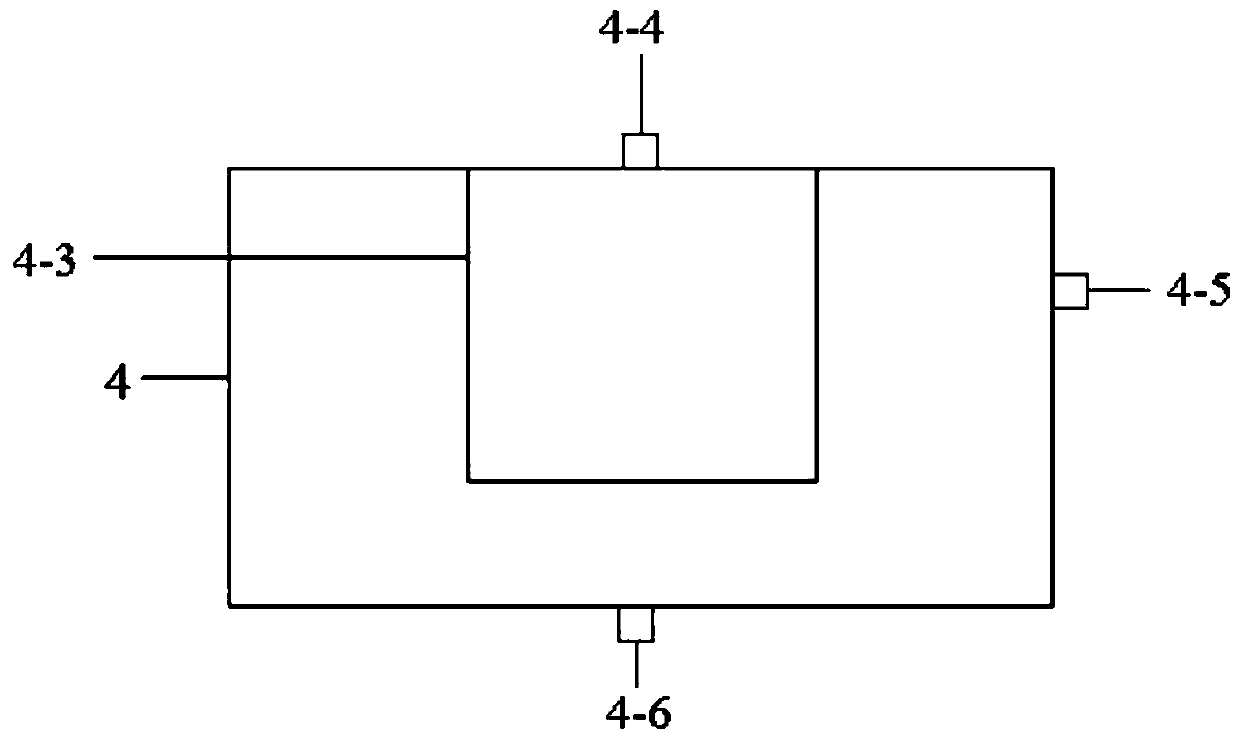

[0044] Specific implementation mode two: the difference between this implementation mode and specific implementation mode one is: if figure 2 As shown, the outer wall of the second crystallizer 4 is a cylindrical structure, and a small cylinder 4-3 coaxial with the outer wall is arranged inside the cylinder, and the diameter of the small cylinder 4-3 is smaller than that of the second crystallizer 4 The diameter of cylinder wall, small cylinder 4-3 is fixed on the inner upper wall of the second crystallizer 4, and there is a gap between the bottom surface of small cylinder 4-3 and the inner bottom surface of the second crystallizer 4, small cylinder 4 The bottom surface of -3 is an open structure, and the liquid inlet 4-4 on the upper surface of the second crystallizer 4 is arranged on the top of the small cylinder 4-3. Others are the same as the first embodiment.

specific Embodiment approach 3

[0045]Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the first solid-liquid separation device 5 is a centrifugal device. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap