Novel separated steel slag and molten steel sampler

A sampler and steel slag technology, applied in sampling, sampling devices, instruments, etc., can solve the problems of high site environment requirements and complex structure of the sampler, and achieve the effects of low price, simple structure and improved internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

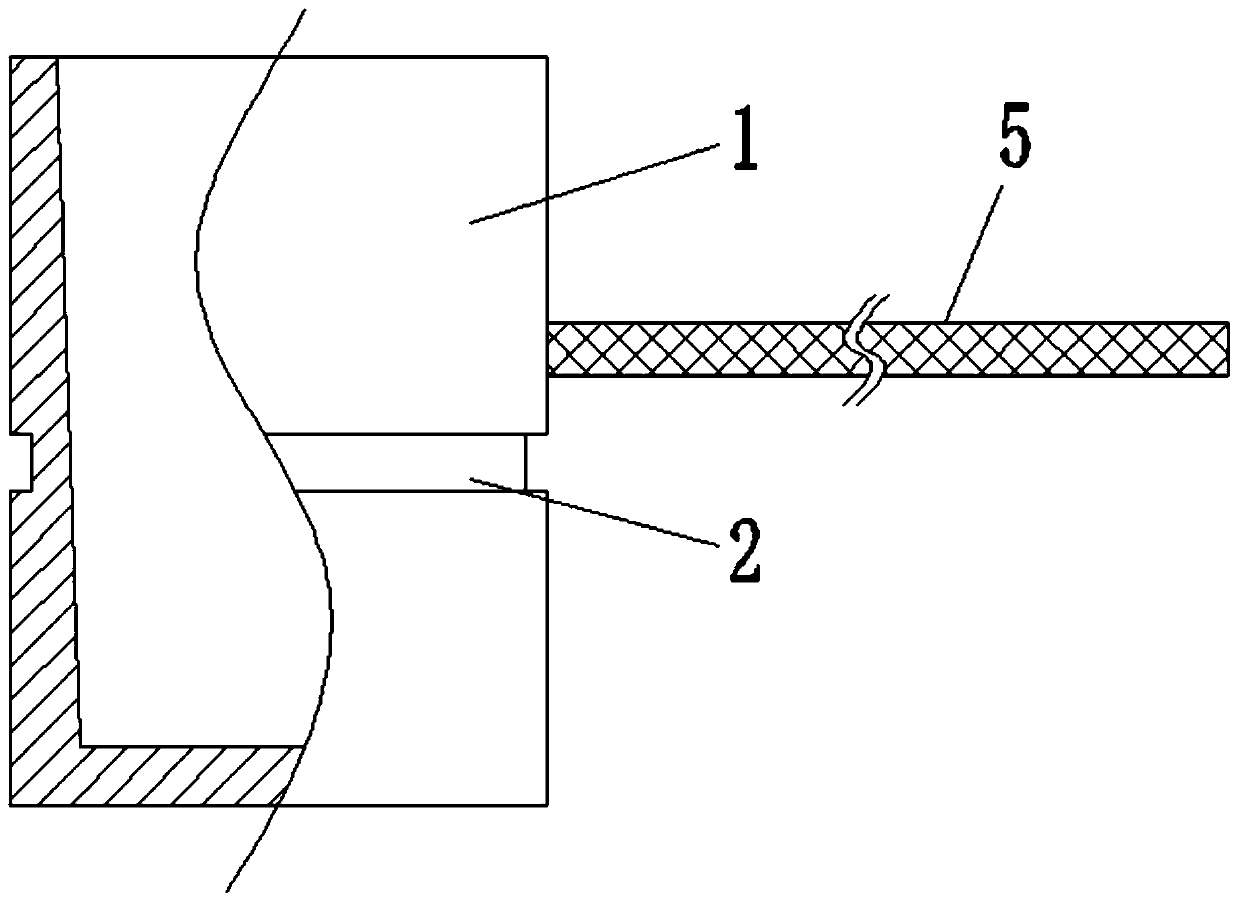

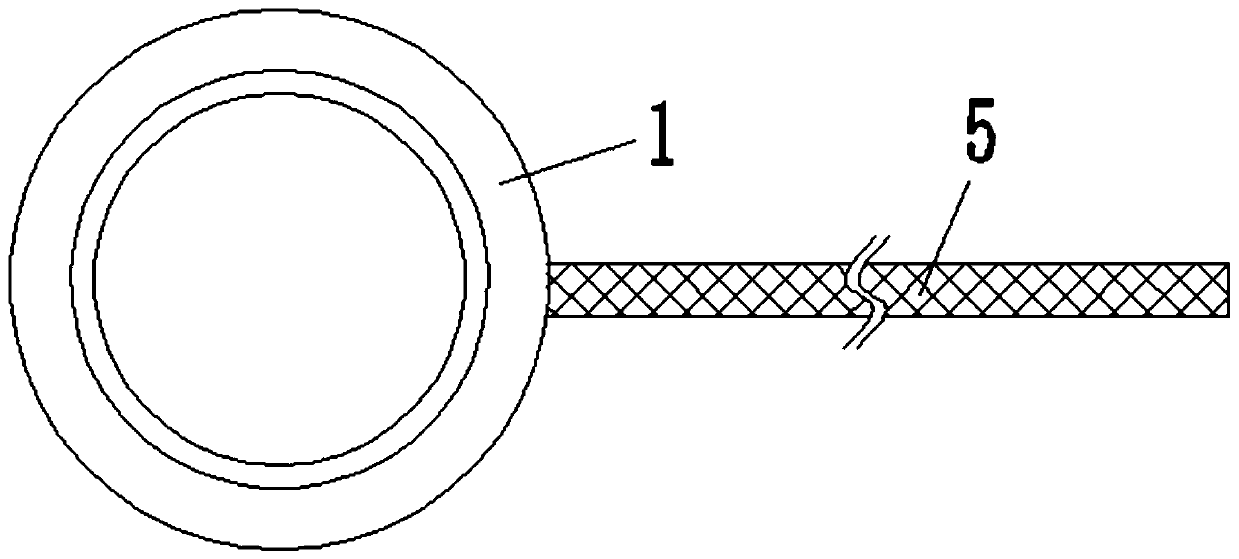

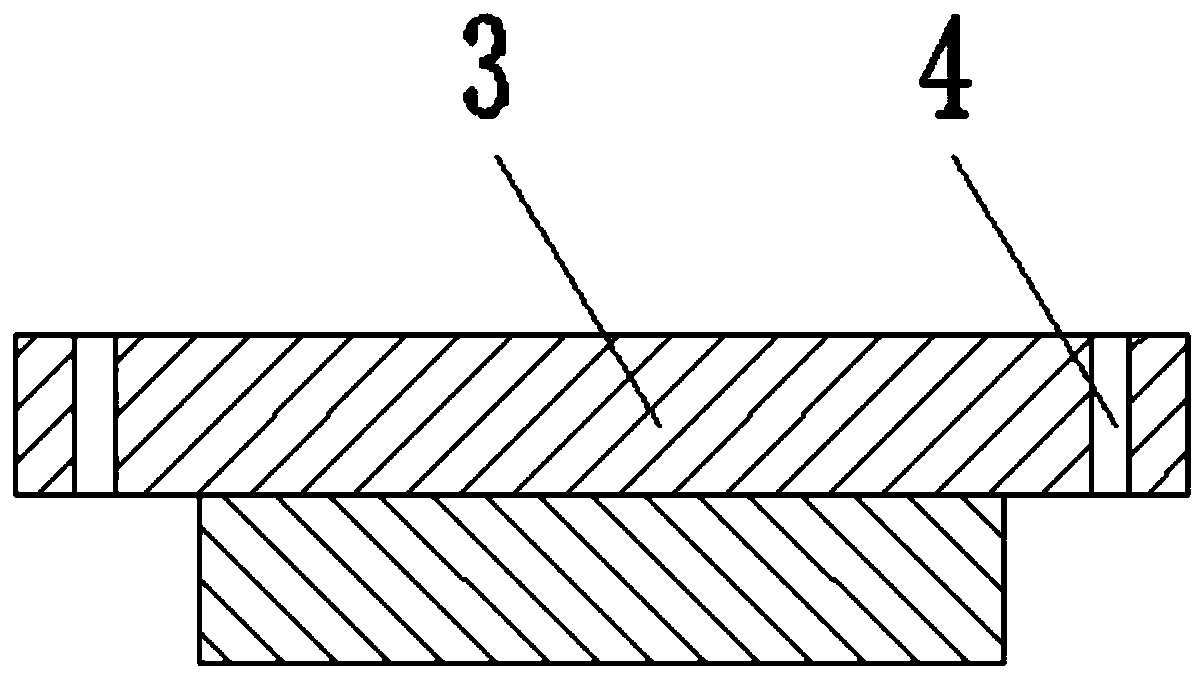

[0018] Such as Figure 1 to Figure 3 As shown, a kind of novel separation steel slag molten steel sampler of the present invention comprises sampler body 1 and wooden cover body 3;

[0019] The wooden cover 3 is arranged on the sampler body 1 by iron wire, the wooden cover 3 and the sampler body 1 form a closed cavity structure, the outer wall of the sampler body 1 is provided with an annular groove 2, and the edge of the wooden cover 3 There are at least one set of locking holes 4 symmetrically. The two ends of the iron wire pass through the locking holes 4 and are tied in the annular groove 2. The inner wall of the sampler body 1 is provided with a taper, the taper is 1.8, and the iron wire is pure iron or carbon. Steel wire, the material of the sampler body 1 is heat-resistant steel.

[0020] Further: a handle 5 is provided on one side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com