Visual detection system and detection method for fireworks products

A technology of visual detection and detection method, which is applied in the direction of measuring devices, optical testing of flaws/defects, and material analysis through optical means. Product qualification rate, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

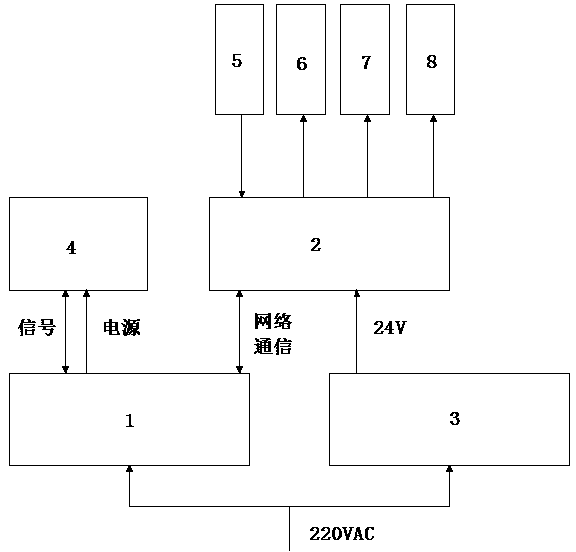

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

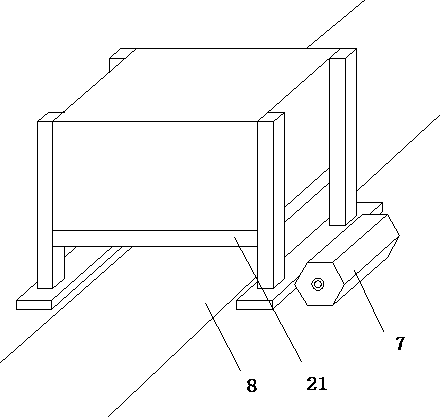

[0030] Embodiment 1, the motion controller 7 controls the position of the imaging unit 2 relative to the fireworks tube 100, such as figure 1 , 2 As shown, the motion controller 7 controls the imaging unit 2 to move along the assembly line 8 to perform imaging processing on the back cover paper 200 and the gunpowder 300 of the fireworks tube 100 .

Embodiment 2

[0031] Embodiment 2, the position control of the fireworks tube 100 relative to the imaging unit 2, such as Figure 5 , 6 As shown, the motion controller 7 controls the fireworks tube 100 to move along the assembly line 8, and the two imaging units 2 respectively perform imaging processing on the back cover paper 200 and the gunpowder 300 of the fireworks tube 100.

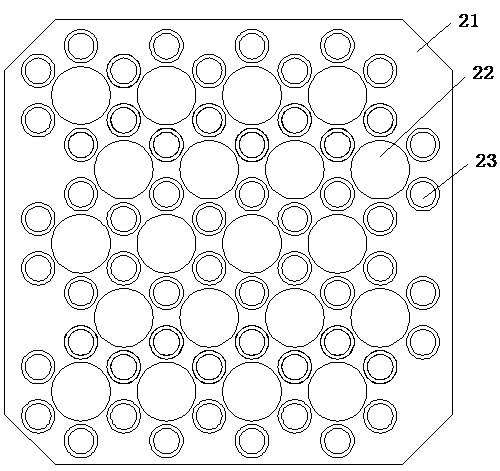

[0032] The imaging unit 2 mainly includes a matrix camera 22 and a light source 23 fixed on an aluminum substrate support 21 .

[0033] The light source 23 is an LED lamp bead with an additional front light-transmitting mirror, and the same number of LED lamp beads are evenly distributed around a single camera.

[0034] The layout of the matrix camera 22 and the setting of the light source 23 are based on the specifications of the fireworks tube 100, and a front light-transmitting lens with a suitable angle is used to illuminate the fireworks tube. The front light-transmitting mirror is a kind of condensing lens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com