Transfer device, transfer chamber and method for preventing corrosion of manipulator

A transmission device and manipulator technology, applied in the direction of conveyor objects, transportation and packaging, electrical components, etc., can solve problems affecting product quality, metal pollution in the process chain, etc., achieve low cost, reduce maintenance costs, and facilitate transformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

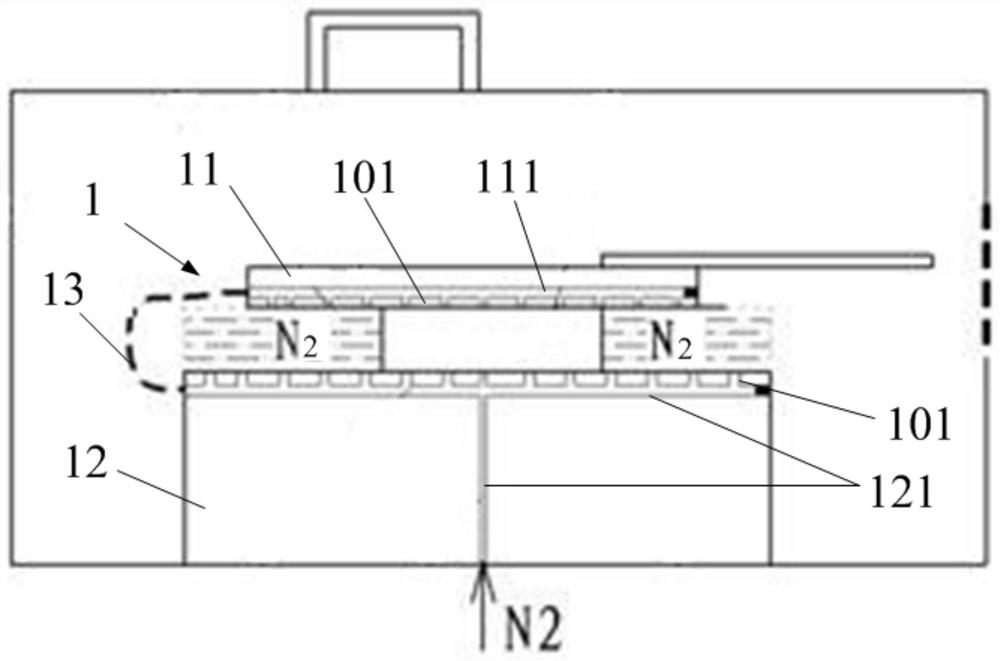

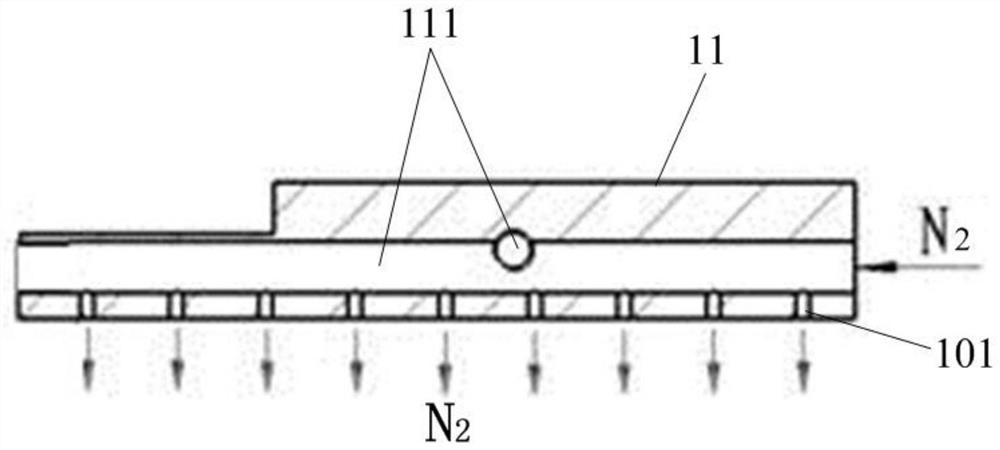

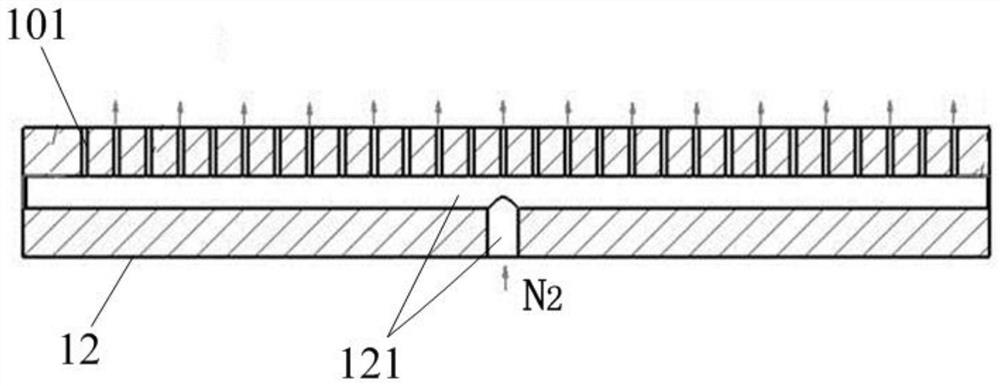

[0033] In order for those skilled in the art to better understand the technical solution of the present invention, the transmission device, the transmission chamber and the method for preventing corrosion of the manipulator provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0034] This embodiment provides a transfer device, which includes a manipulator and a conveying air path, the manipulator is used to transfer wafers, and the gas outlet end of the conveying air path is arranged on the outer surface of the manipulator, or is located near the manipulator to pass the output The shielding gas forms a gas shield around the manipulator. Wherein, the manipulator may be one component or multiple components in the transmission chamber, which can be specifically set according to the equipment conditions of the transmission chamber, which is not specifically limited in this embodiment.

[0035] The transport device provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com