Solar cell piece and precision determining method

A technology for solar cells and cells, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as abnormality that cannot be found in time, poor matching between wire grooves and aluminum grid lines, and poor batch performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

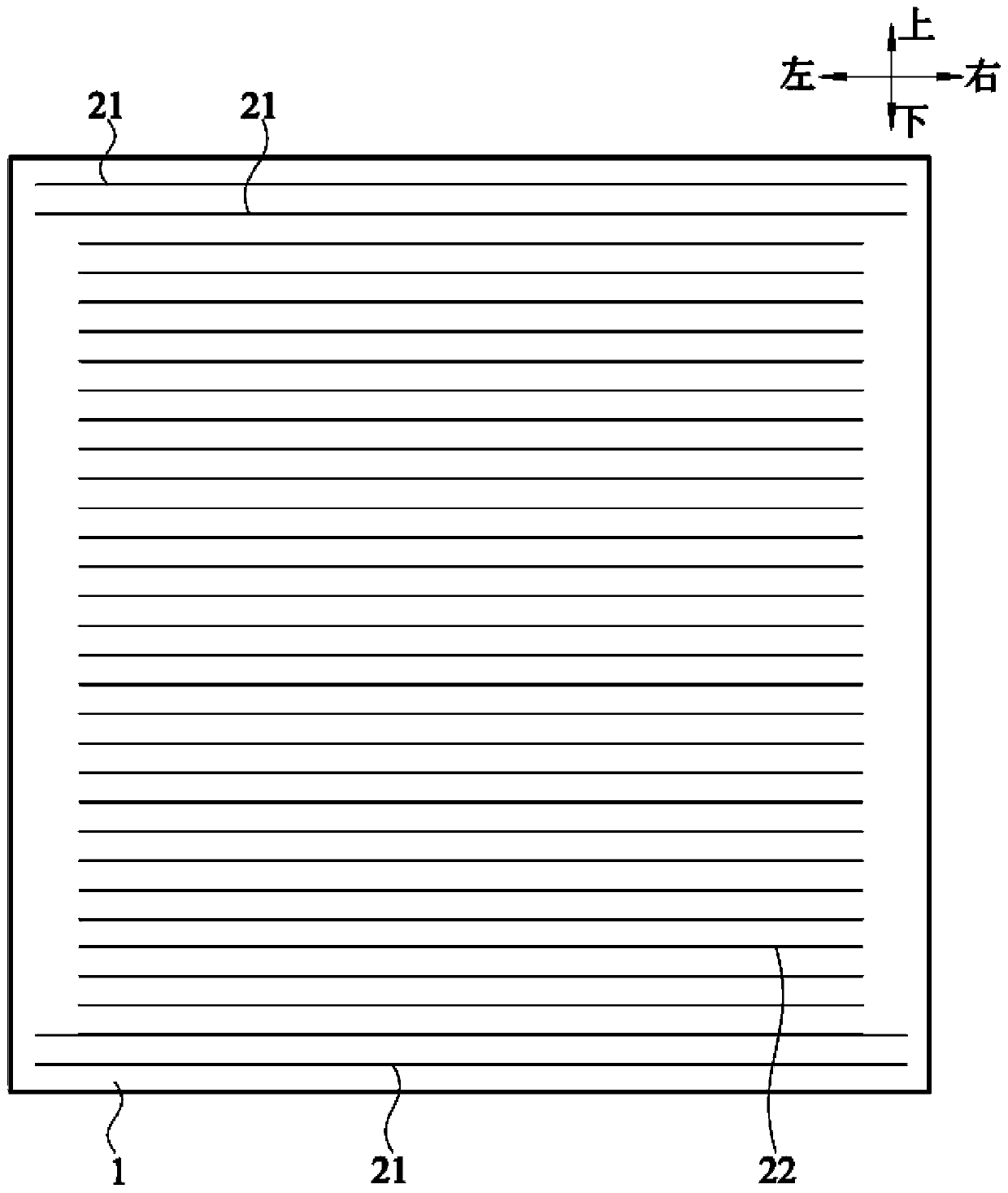

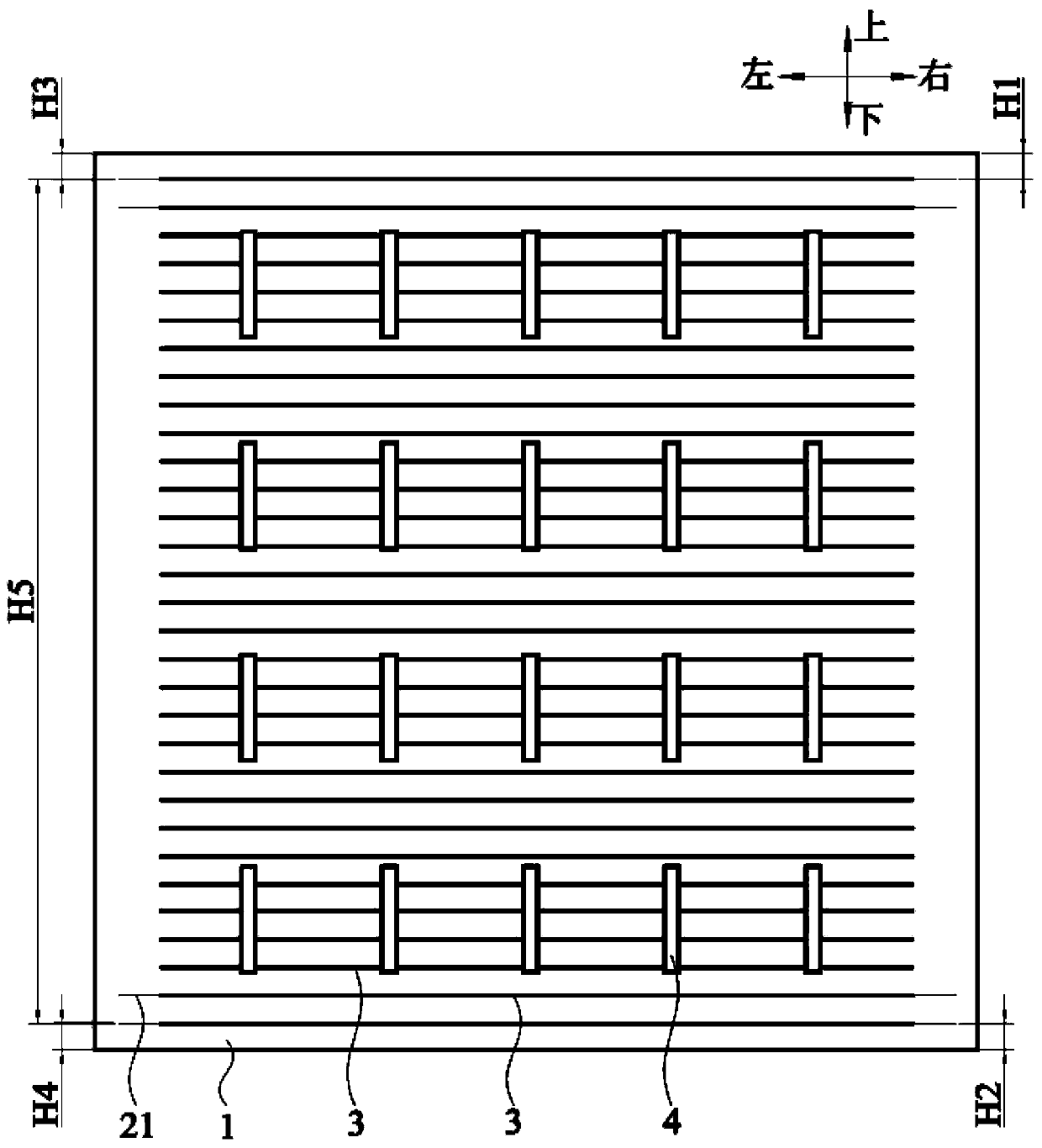

[0039] This embodiment provides a solar battery sheet, and the solar battery sheet may be a double-sided PERC battery. Such as figure 1 and figure 2 As shown, the solar cell includes a cell body 1 and a plurality of aluminum grid lines 3 and bus bars 4 arranged on the back of the cell body 1 , the aluminum grid lines 3 and the bus bar 4 are perpendicular to each other. The cell body 1 includes a silicon nitride film on the back, an aluminum oxide film, a P-type silicon, an N-type emitter and a silicon nitride film on the front side stacked in sequence from bottom to top. In order to connect the aluminum grid line 3 to the P-type silicon so as to form an ohmic contact so as to achieve the purpose of collecting electrons, a slot structure is also arranged on the back of the cell body 1, and the slot structure is arranged on the silicon nitride film on the back , and penetrate the silicon nitride film and the aluminum oxide film on the back side, so as to expose the P-type sil...

Embodiment 2

[0049] This embodiment provides a method for judging the accuracy of a solar cell, which can be used for the solar cell in Embodiment 1.

[0050] Specifically, the length of the correction wire slot 21 is greater than the length of the aluminum grid line 3, after printing the aluminum grid line 3, by observing whether the unshielded end of the calibration wire slot 21 and the corresponding aluminum grid line 3 are on the same straight line, it can be Judging the overlap between the aluminum grid line 3 and the wire slot.

[0051] In this embodiment, the coincidence of the aluminum grid wire 3 and the wire groove can be judged by visual observation, which is convenient and simple, and does not require other auxiliary equipment. Abnormalities can be detected in time to avoid poor batch performance of products.

Embodiment 3

[0053] The positional deviation between the aluminum grid wire 3 and the wire groove generally has two factors, one is the processing accuracy of the wire groove, and the other is the printing accuracy of the printing screen. When it is judged that there is a deviation between the position of the aluminum grid line 3 and the limit position through the accuracy judgment method in Example 2, in order to conveniently and accurately adjust the production line equipment and precision, so as to ensure the yield rate of the battery sheet, it is necessary to judge the aluminum grid line 3 Influencing factors of the positional deviation from the limit.

[0054] The accuracy judging method provided in this embodiment can judge whether there is an accuracy error in the slotted structure, so as to quickly determine the cause of the abnormality of the production line.

[0055] Specifically, on the basis of the solar cells provided in Embodiment 1, respectively detect the arrangement direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com