Preparation method of diaphragm containing solid electrolyte coating and application of diaphragm containing solid electrolyte coating

A solid electrolyte and separator technology, applied in solid electrolyte, electrolyte battery manufacturing, electrolyte and other directions, can solve the problems of low first-efficiency capacitor retention rate, low battery lithium conductivity, etc., to overcome the strong shuttle effect, inhibit the amount of dissolution, The effect of improving battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

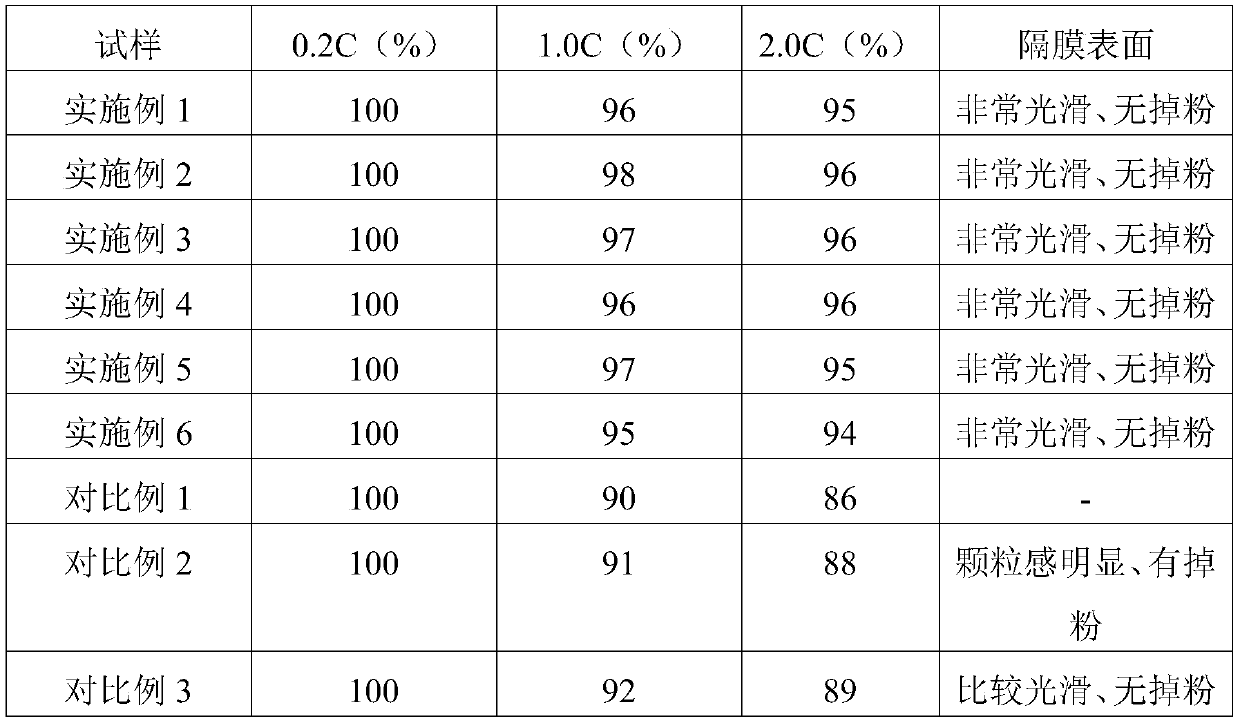

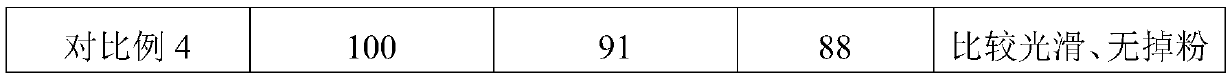

Examples

Embodiment 1

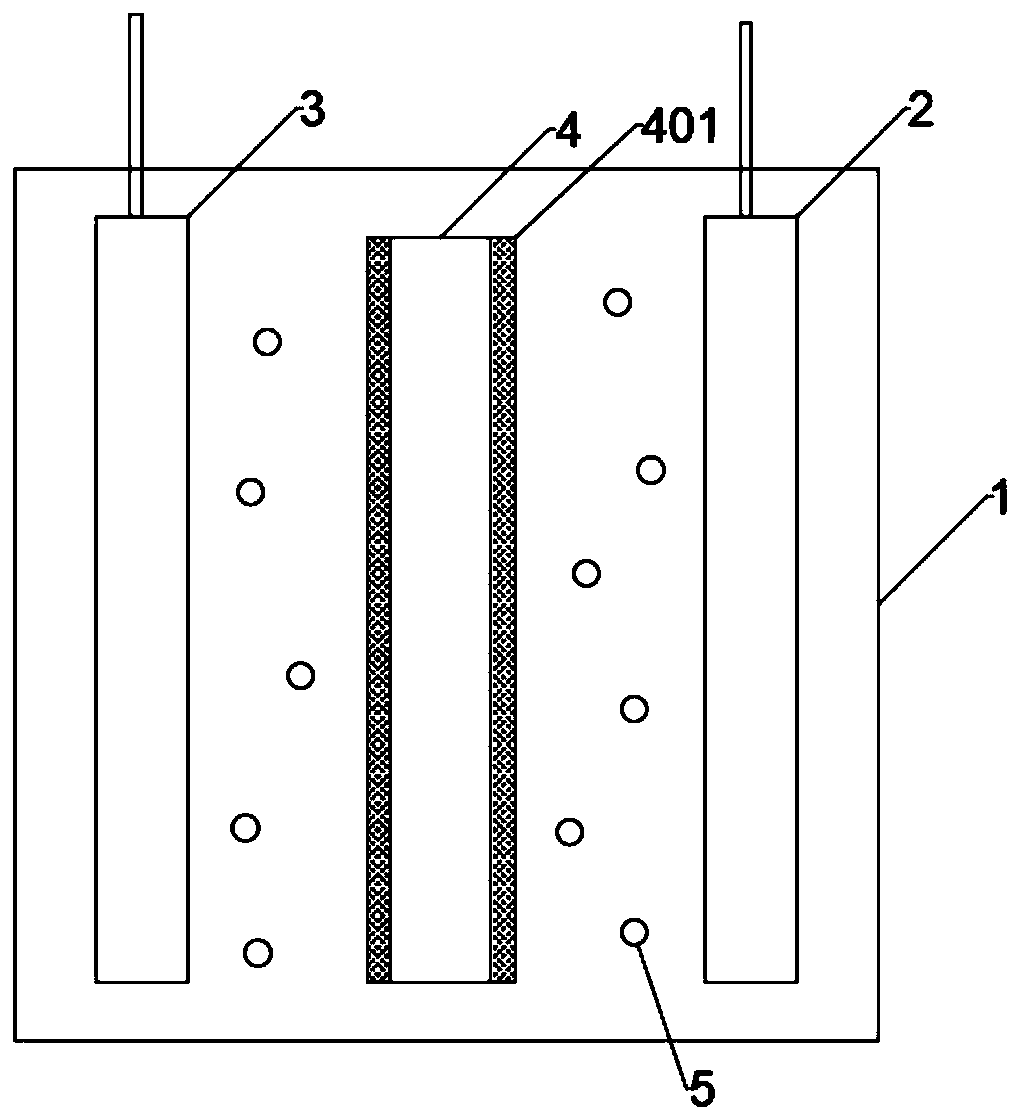

[0025] A diaphragm containing a solid electrolyte coating, comprising a diaphragm base film 4 and a solid electrolyte coating 401, the thickness of the solid electrolyte coating 401 is 5 μm, and the solid electrolyte coating 401 evenly covers both surfaces of the diaphragm base film 4;

[0026] The solid electrolyte coating 401 includes the following raw materials, calculated in parts by weight, 0.5 parts of dispersant, 10 parts of solid electrolyte, 1 part of binder, 100 parts of solvent A, and 100 parts of solvent B.

[0027] The material of the diaphragm base film 4 is polyethylene.

[0028] A preparation method for a diaphragm containing a solid electrolyte coating, comprising the following steps:

[0029] S1: first disperse the dispersant into solvent A to obtain a dispersion solution, then spray the dispersion solution into a container with a solid electrolyte through an atomizing nozzle, and stir for 1 hour at the same time, the stirring speed is 800r / min, and the prepa...

Embodiment 2

[0042] A diaphragm containing a solid electrolyte coating, comprising a diaphragm base film and a solid electrolyte coating, the thickness of the solid electrolyte coating is 10 μm, and the solid electrolyte coating evenly covers both surfaces of the diaphragm base film;

[0043] The solid electrolyte coating includes the following raw materials, calculated in parts by weight, 1 part of dispersant, 25 parts of solid electrolyte, 3 parts of binder, 100 parts of solvent A, and 100 parts of solvent B.

[0044] The material of the diaphragm base film is polyethylene.

[0045] A preparation method for a diaphragm containing a solid electrolyte coating, comprising the following steps:

[0046] S1: first disperse the dispersant into solvent A to obtain a dispersion solution, then spray the dispersion solution into a container with a solid electrolyte through an atomizing nozzle, and stir for 2 hours at the same time at a stirring rate of 800r / min. get dispersion slurry;

[0047] S2...

Embodiment 3

[0059] A diaphragm containing a solid electrolyte coating, comprising a diaphragm base film 4 and a solid electrolyte coating 401, the thickness of the solid electrolyte coating 401 is 20 μm, and the solid electrolyte coating 401 evenly covers both surfaces of the diaphragm base film 4;

[0060] The solid electrolyte coating 401 includes the following raw materials, calculated in parts by weight, 2 parts of dispersant, 40 parts of solid electrolyte, 5 parts of binder, 100 parts of solvent A, and 100 parts of solvent B.

[0061] The material of the diaphragm base film 4 is polyacrylonitrile.

[0062] A preparation method for a diaphragm containing a solid electrolyte coating, comprising the following steps:

[0063] S1: first disperse the dispersant into solvent A to obtain a dispersion solution, then spray the dispersion solution into a container with a solid electrolyte through an atomizing nozzle, and stir for 3 hours at the same time, with a stirring speed of 800r / min. get...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com