linear motor

A technology for linear motors and machines, applied in circuits, magnetic objects, mechanical equipment, etc., to solve problems such as bulkiness, increase in overall equipment cost and size, and damage to the integrity of input functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

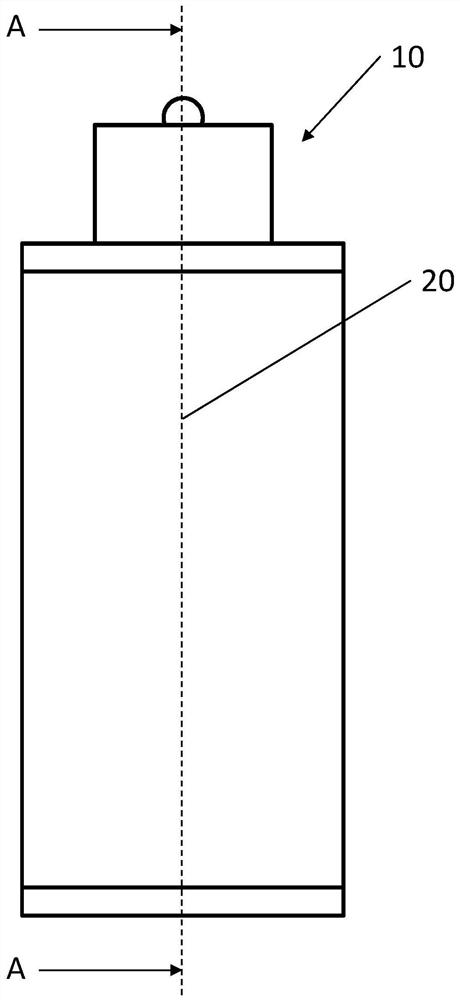

[0065] figure 1 is an external view of a first LEM operating as an actuator 10 with an axis of motion 20 along which a translating body (shown later) moves along the axis of motion 20 and the various planar positions for the other cross-sectional views.

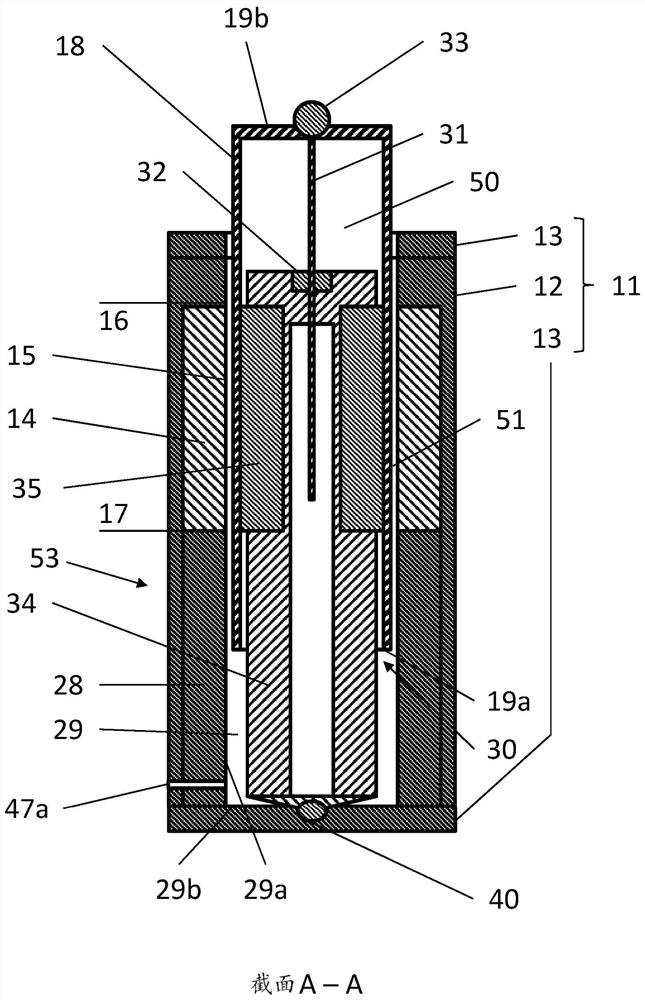

[0066] figure 2 The actuator 10 is shown with a housing body 11 . The housing body 11 is formed by a typically cylindrical wall 12 and by end walls 13 so as to define a hollow interior. Inside holds a stator 14 which is typically a tubular linear motor stator having a cylindrical bore 15 extending axially from one end 16 to the other 17 of the stator. Thus, the housing body and the stator define the working cylinder 53 . The central core 34 is fixed at least axially within the working cylinder relative to the stator 14 and in this arrangement the central core 34 is fixed to the end wall 13 at a central core fixing point 40 . The upper end of the central core 34 is surrounded by the hollow translating body 18 such that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com