Alpha-phase nano-alumina reinforced polyetheretherketone biocomposite and preparation method thereof

A nano-alumina, polyetheretherketone technology, applied in drug delivery, tissue regeneration, pharmaceutical formulations, etc., can solve the problems of serious agglomeration effect, poor interface compatibility, and unsatisfactory performance, and achieve good application prospects and high stability. The effect of excellent biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

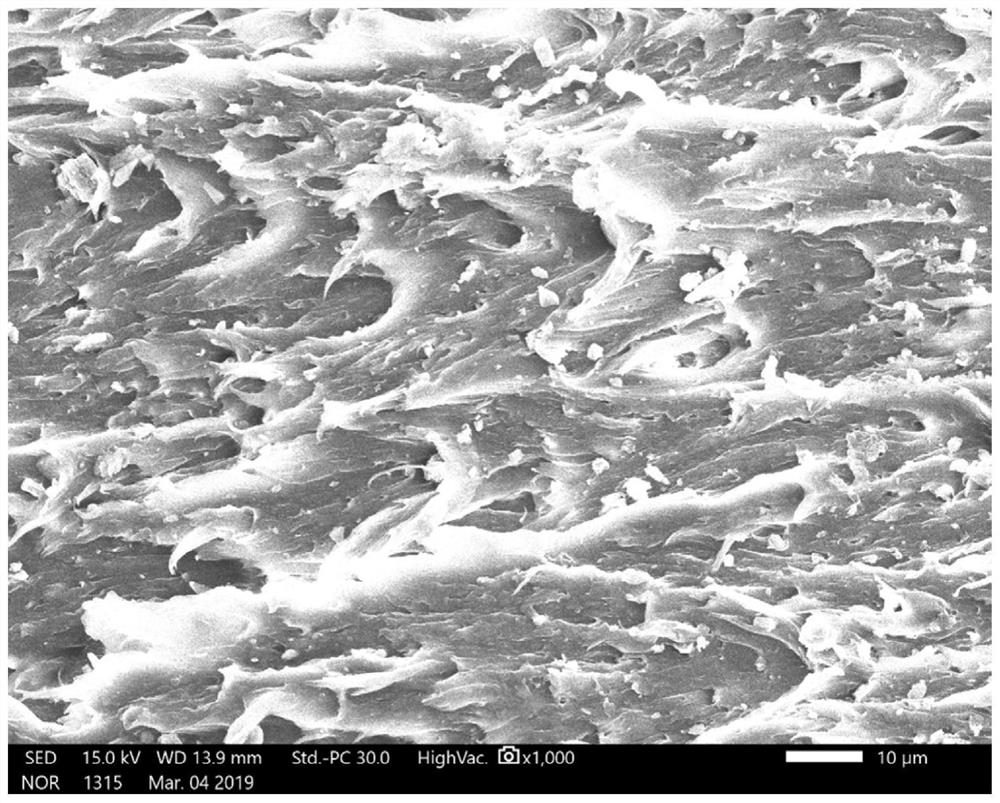

[0024] Weigh 85g of polyether ether ketone powder with a particle size of 50 μm, 15 g of α nano-alumina powder with a particle size of 30 nm, 1 g of polytetrafluoroethylene powder with a particle size of 15 μm, and 5 g of hydroxyapatite with a particle size of 60 nm. Put each weighed raw material into a vacuum drying oven, and dry at 120° C. for 12 hours until the moisture is completely removed, and set aside.

[0025] Add 100 mL of absolute ethanol to the beaker at room temperature, then add the dried α nano-alumina powder, and magnetically stir at a speed of 500 r / min for 1 h to obtain a suspension. Then slowly add other dry raw materials (including polyetheretherketone powder, polytetrafluoroethylene powder, hydroxyapatite, the same below) and 2g of silane coupling agent KH560 into the suspension, and continue stirring at the same speed at room temperature After 1 h, a polyether ether ketone / alumina suspension was obtained. The suspension was placed in an ultrasonic water ...

Embodiment 2

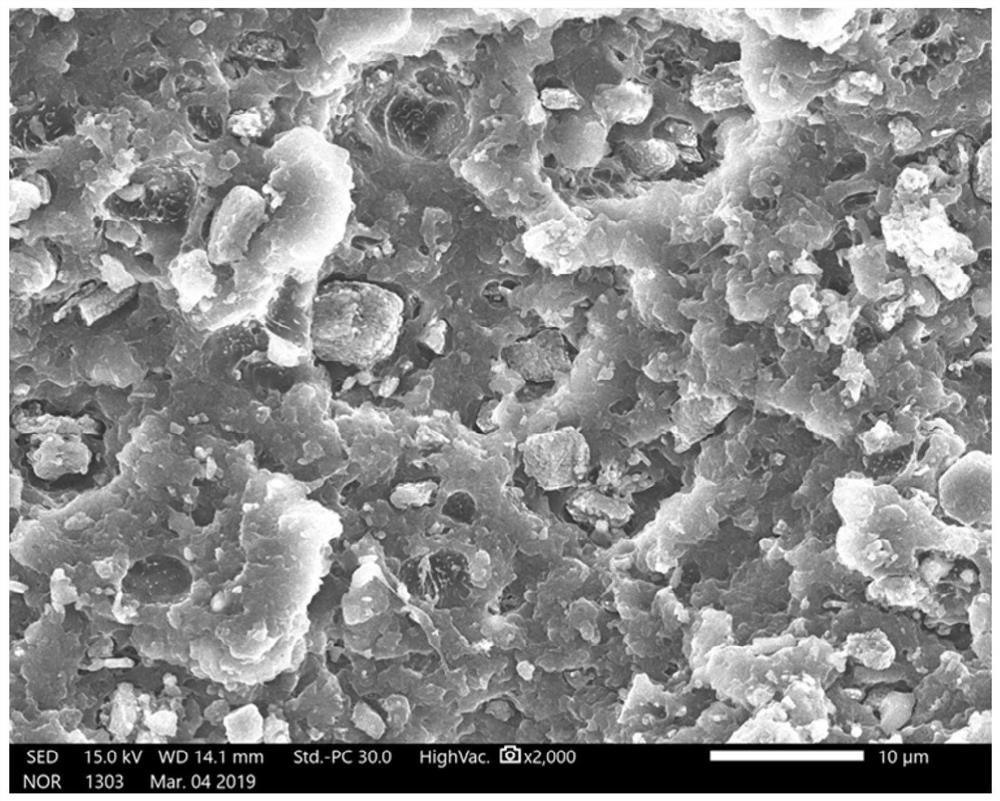

[0028] Weigh 95g of polyether ether ketone powder with a particle size of 50 μm, 5 g of α nano-alumina powder with a particle size of 30 nm, 1 g of polytetrafluoroethylene powder with a particle size of 15 μm, and 5 g of hydroxyapatite with a particle size of 60 nm. Put each weighed raw material into a vacuum drying oven, and dry at 150° C. for 3 hours until the moisture is completely removed, and set aside.

[0029] Add 100 mL of absolute ethanol to the beaker at room temperature, then add the dried α nano-alumina powder, and stir magnetically at a speed of 500 r / min for 1 h to obtain a suspension. Then other dried raw materials and 2 g of silane coupling agent KH560 were slowly added to the suspension, and stirring was continued at room temperature for 1 h at the same speed to obtain a polyether ether ketone / alumina suspension. The suspension was placed in an ultrasonic water bath device, and ultrasonically treated at room temperature at a frequency of 50-60KHz for 2h. The mi...

Embodiment 3

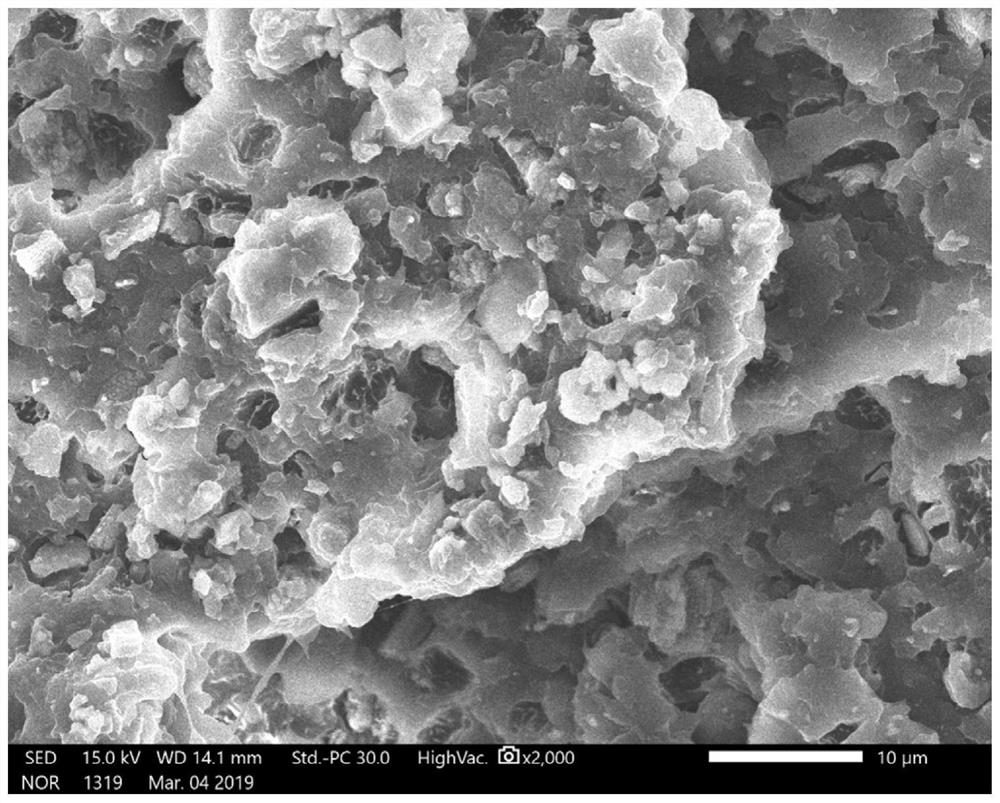

[0032] Weigh 85g of polyether ether ketone powder with a particle size of 50 μm, 15 g of α nano-alumina powder with a particle size of 200 nm, 1 g of polytetrafluoroethylene powder with a particle size of 15 μm, and 5 g of hydroxyapatite with a particle size of 60 nm. Put each weighed raw material into a vacuum drying oven, and dry at 120° C. for 12 hours until the moisture is completely removed, and set aside.

[0033] Add 100 mL of absolute ethanol to the beaker at room temperature, then add the dried α nano-alumina powder, and magnetically stir at 800 r / min for 0.5 h to obtain a suspension. Then other dried raw materials and 2g of silane coupling agent KH560 were slowly added to the suspension, and stirring was continued at room temperature at the same speed for 0.5h to obtain a polyether ether ketone / alumina suspension. The suspension was placed in an ultrasonic water bath device, and ultrasonically treated at room temperature at a frequency of 50-60KHz for 2h. The mixtur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com