Substitute bogie assembly and alighting method

A bogie and assembly technology, which is applied in the field of rail vehicles, can solve the problems of being unsuitable for mass production, less off-board processes, and difficult to apply to the assembly of low-floor trams, etc., and achieves simple structure, small size, and low production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

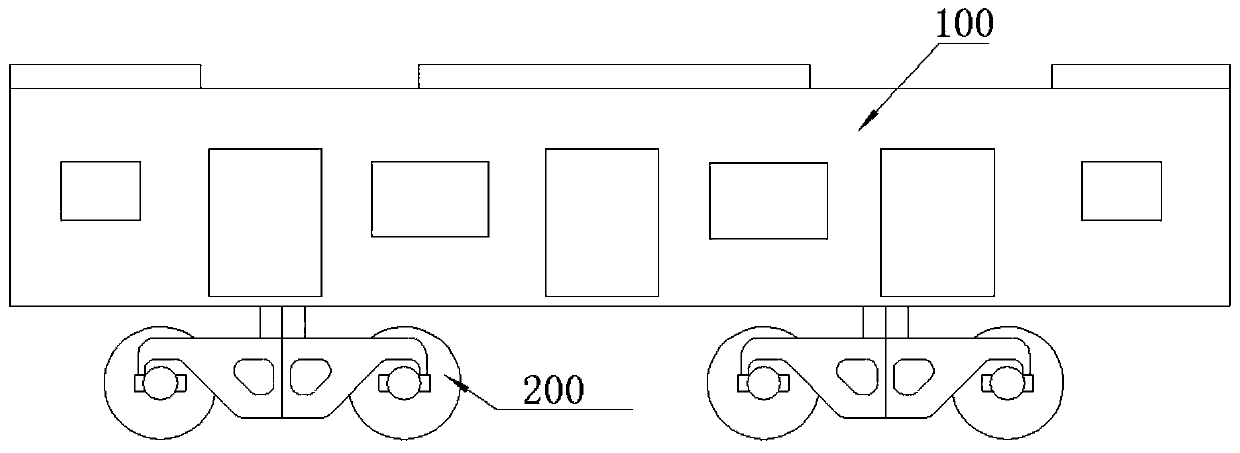

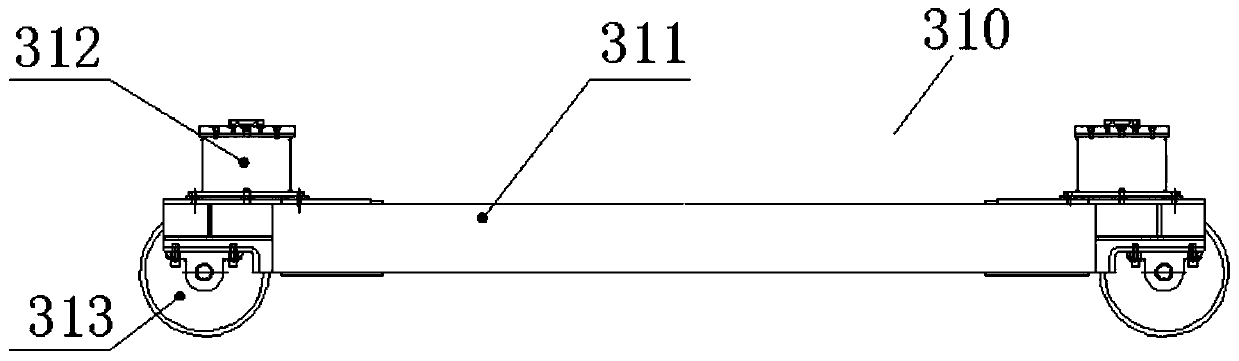

[0063] Such as Figure 10 As shown, core shafts 210 are distributed symmetrically at the four corners of the bottom of the car body 100 in the middle compartment. When getting off the car, only the first-generation bogie 310 is selected, and the four cylindrical mandrels 210 of the car body 100 are respectively inserted into the fixed disks 3122 of the fixing devices 312 at the four corners of the first-generation bogie 310. In the hole, the car can be dropped off.

Embodiment 2

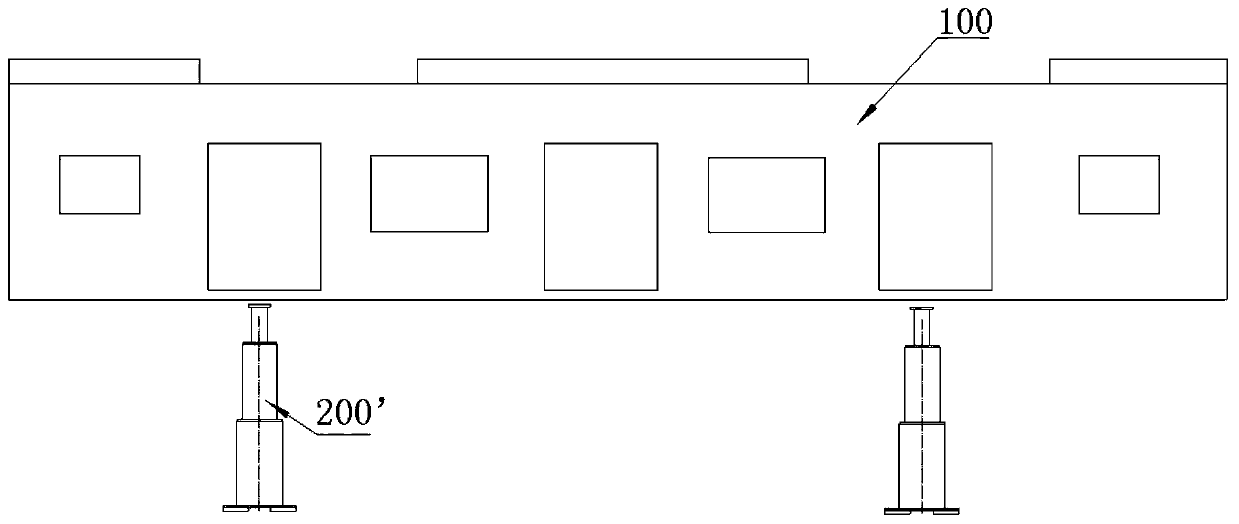

[0065] Such as Figure 11 As shown, the bottom of the vehicle body 100 of the leading vehicle has four spindles 210 distributed asymmetrically. When getting off the car, the bogie 310 for the first generation and the bogie 320 for the second generation can be used in combination. First, the pin shaft is inserted into the first connection device 314 of the first substitute bogie 310 and the second connection device 324 of the second substitute bogie 320 to make it combined into a whole; secondly, the four cylindrical cores of the car body 100 The shafts are respectively inserted into the fixed disks 3122 of the fixing devices 312 at the four corners of the first substitute bogie 310; The lower surface of 100 can be finished getting off the car.

Embodiment 3

[0067] Such as Figure 12 As shown, the bottom of the car body 100 of the middle compartment is not arranged with a mandrel. When getting off the car, select a pair of bogies 330 for the third generation to fix the two ends of the car body 100 respectively. First, the position of the four corners of the end of the car body 100 is installed with a positioning tool 231 that includes a positioning pin; secondly, insert the positioning pin of the positioning tool 231 into the round hole of the fixing seat 334 of the third substitute bogie 330 to Position the car body 100, and unscrew the threaded support 3222 to fit it to the lower surface of the car body 100 to support the car body 100; and finally, disassemble the positioning tooling 231 at both ends of the car body to complete the landing.

[0068] It should be understood that the third-generation bogie 330 is not only applicable to the vehicle body 100 without a mandrel arranged at the bottom, but also applicable to a car bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com