Outdoor unit packaging bottom support and air conditioner outdoor unit assembly

An air conditioner outdoor unit and outdoor unit technology, which is applied to special packaging objects, packaging, air conditioning systems, etc., can solve the problems of increased weight of air conditioner outdoor unit components, unfavorable air conditioner outdoor unit economy, and unfavorable air conditioner outdoor unit handling, etc. The effect of improving transportation economy, improving production economy, improving structural stability and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Examples of outdoor unit packaging bottom bracket and air conditioner outdoor unit components:

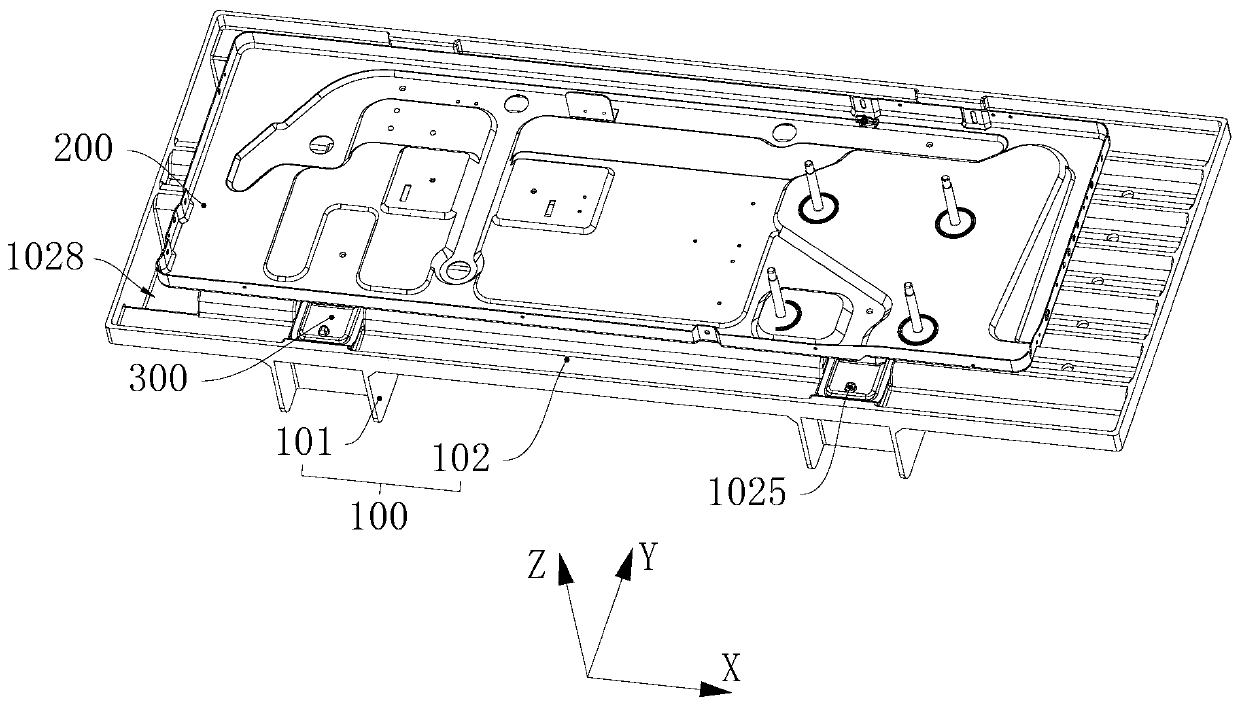

[0028] This example refers to figure 1 The coordinate system is described.

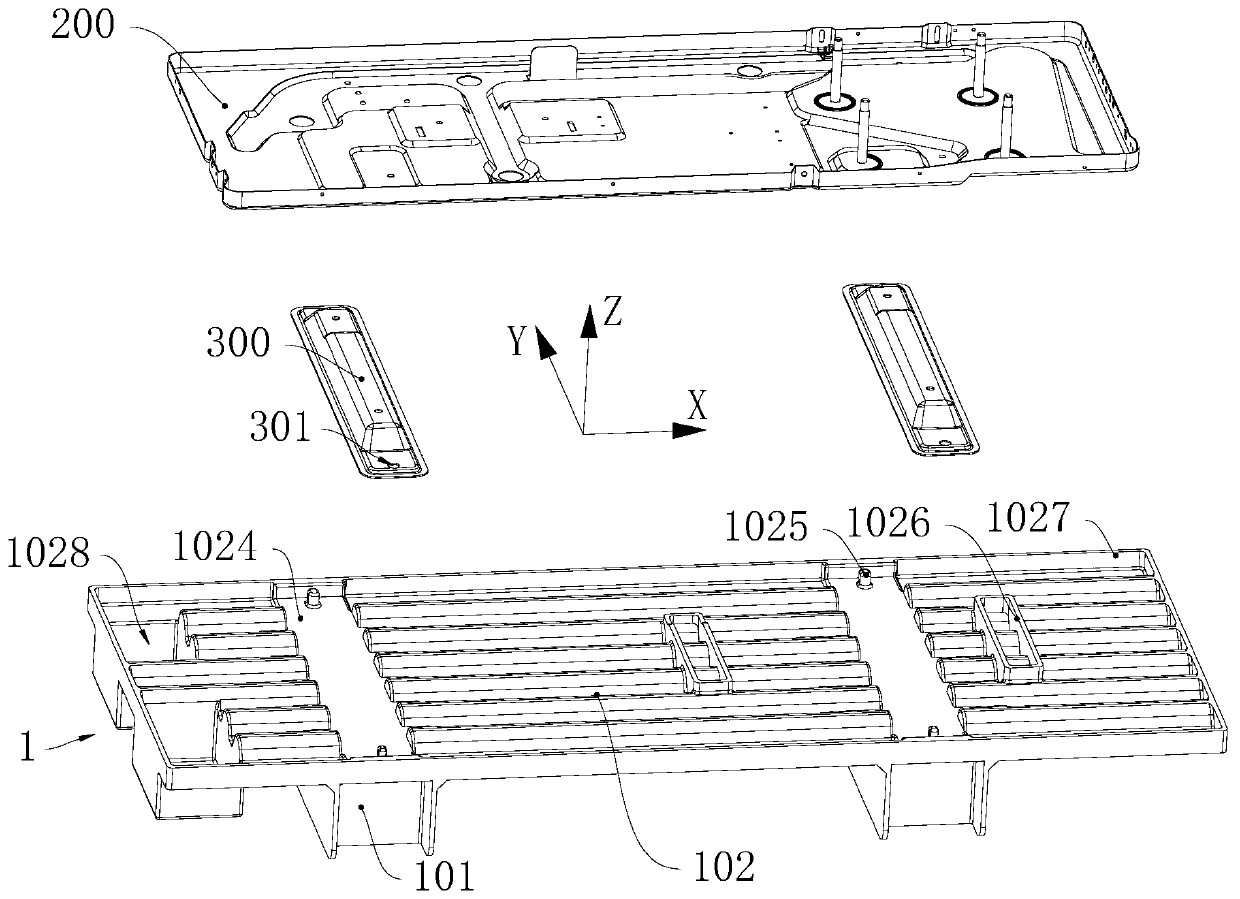

[0029] Please refer to figure 1 and figure 2 , the air conditioner outdoor unit assembly of this embodiment includes an air conditioner outdoor unit and the outdoor unit packaging base 100 of this embodiment, the air conditioner outdoor unit has a chassis 200 and two strip-shaped installation feet 300, and the length direction of the installation feet 300 is along the In the Y-axis direction, two installation feet 300 are distributed along the X-axis at intervals, and the two installation feet 300 are fixed on the bottom wall of the chassis 200 .

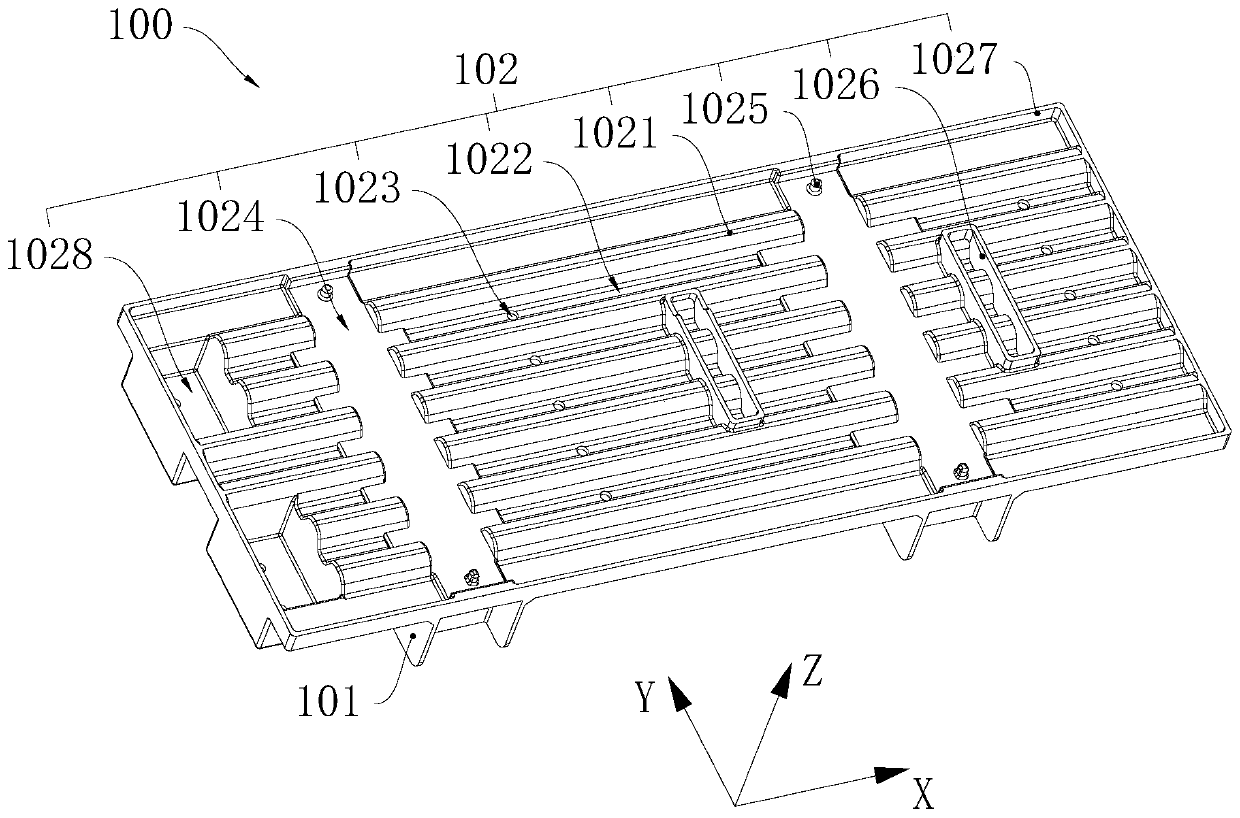

[0030] Please refer to image 3 , the outdoor unit packaging base 100 of this embodiment includes an upper plank 102 and two supporting strips 101, the length direction of the two supporting strips 101 is along the Y-axis direction, and the two suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com