Terminal cutting and packaging machine and packaging method thereof

A packaging machine and terminal technology, which is applied in the direction of transportation and packaging, conveyor objects, contact parts manufacturing, etc., can solve the problems of increasing the extra man-hours of terminal production, reducing the cutting speed of terminals, and reducing the production efficiency of terminals, so as to overcome the low efficiency , Reduce transfer frequency, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solution of the present invention will be clearly and completely described below in conjunction with the drawings and embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

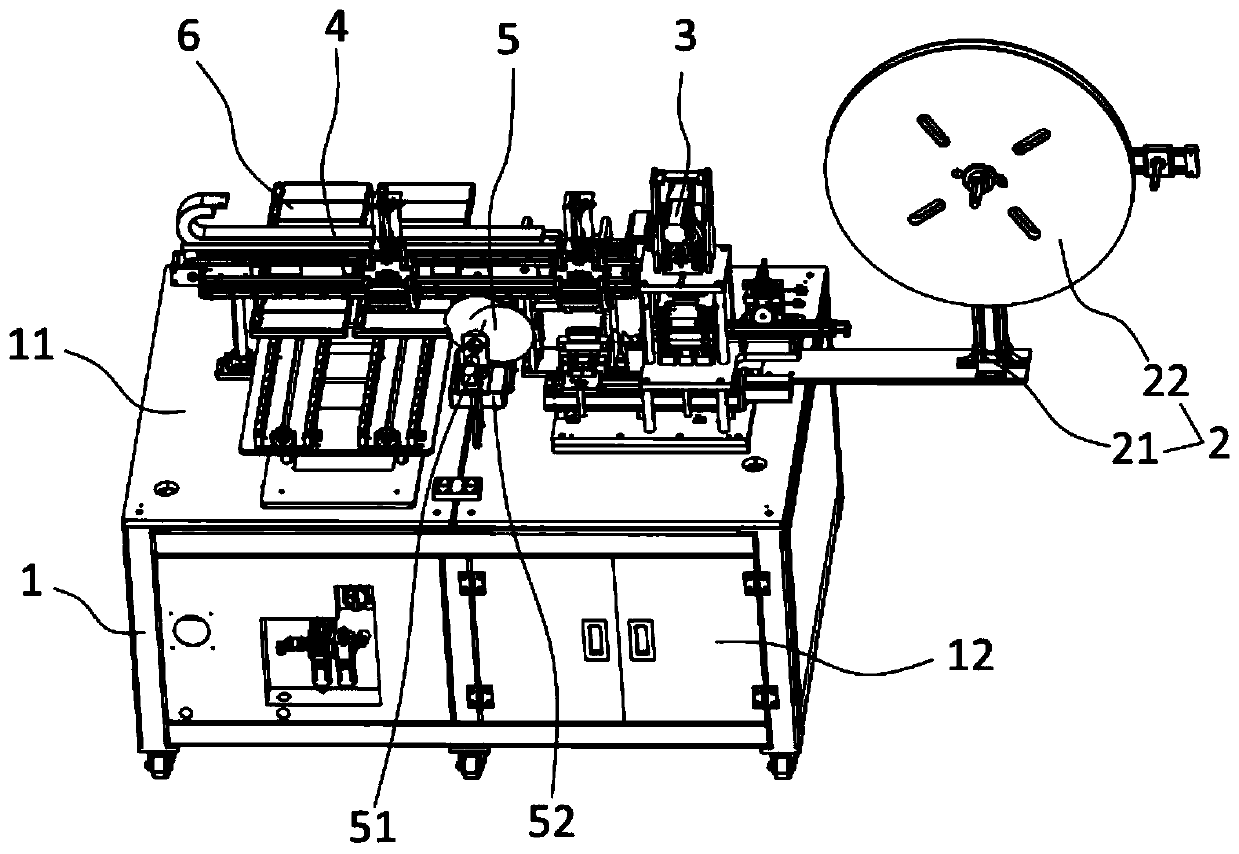

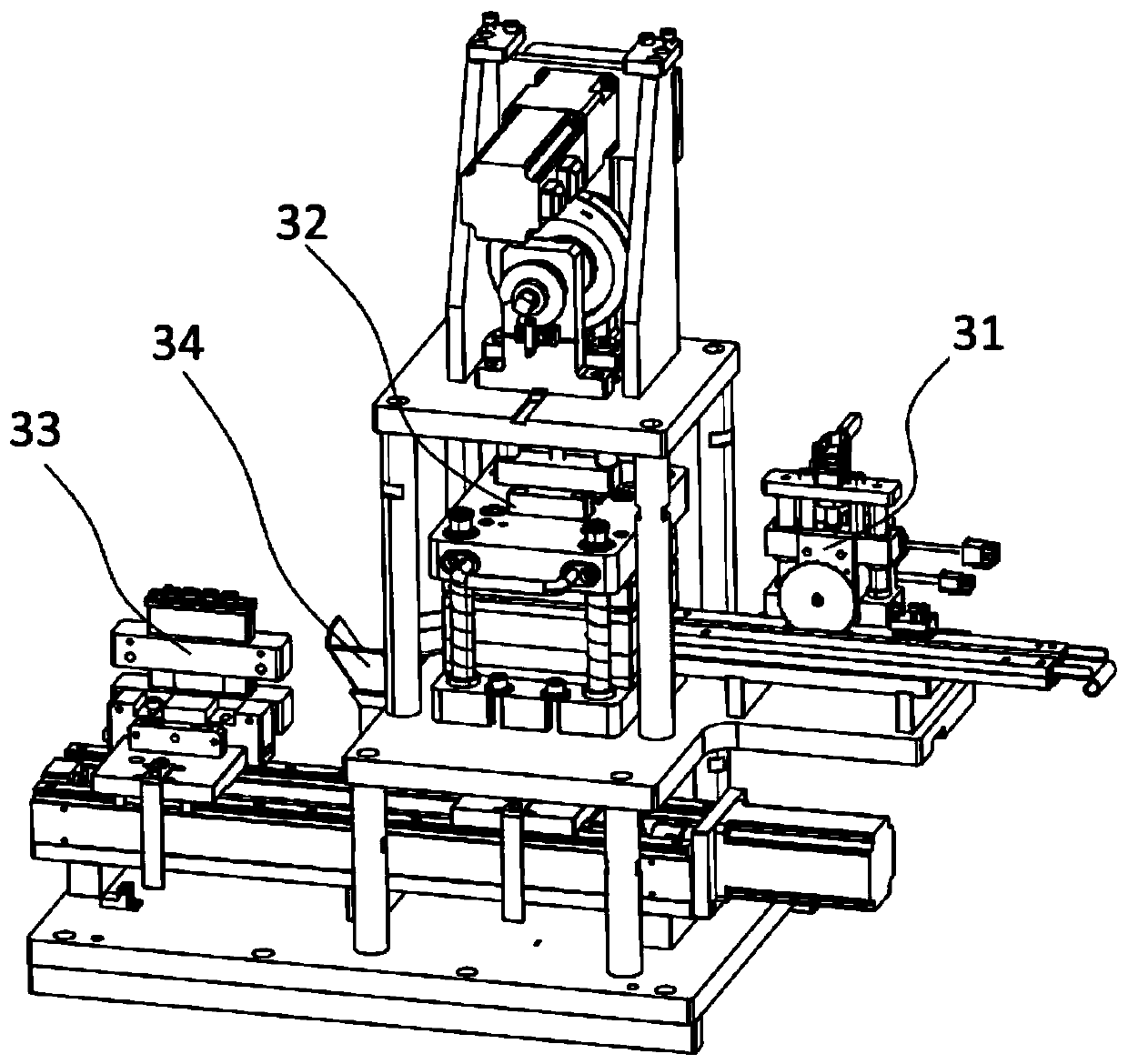

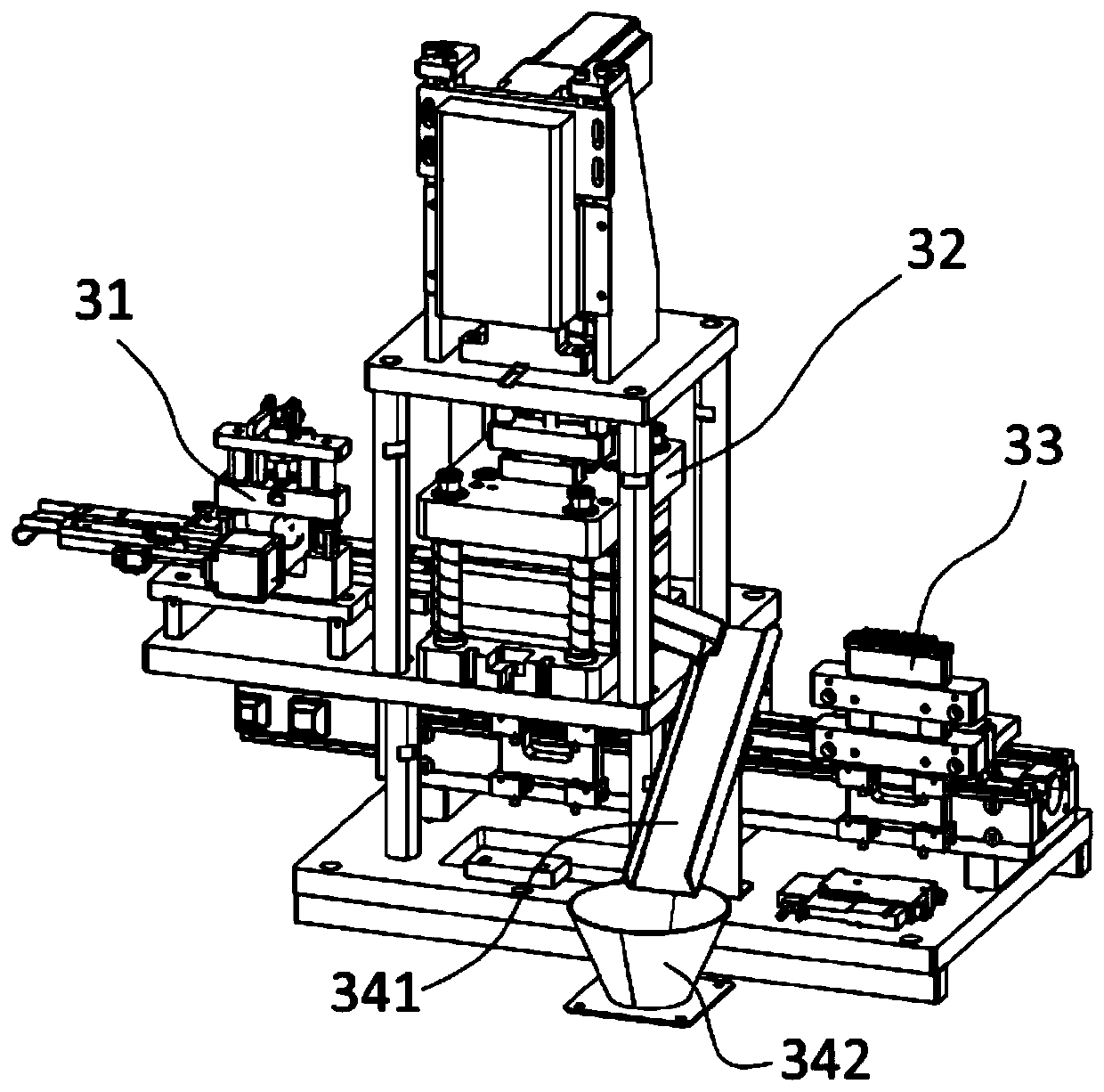

[0047] Such as figure 1 As shown, the terminal cutting and packaging machine proposed by the present invention includes: a frame 1, a feeding mechanism 2, a cutting module 3, a handling mechanism 4, a detection mechanism 5, and a product packaging station 6.

[0048] Specifically, the frame 1 includes a workbench 11 and a box body 12 arranged under the workbench 11. The frame 1 is mainly made of stainless steel, which can improve the overall rigidity of the frame 1 and prevent the frame 1 from being affected by the environment. Corrosion, the box body 12 is mainly used to set up various controllers and wiring arrangements. Open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com