Two-span continuous-construction steel-mixed composite bridge construction method adopting back rope type bridge erecting machine

A technology of bridge construction and bridge erection machine, applied in the direction of erection/assembly of bridges, bridges, bridge construction, etc., can solve the problems of unfavorable stress on steel beams and side spans, slow construction speed, low equipment utilization rate, etc. Moment cracking problem, construction speed increase, and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

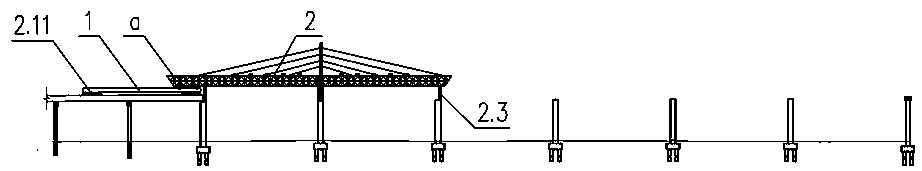

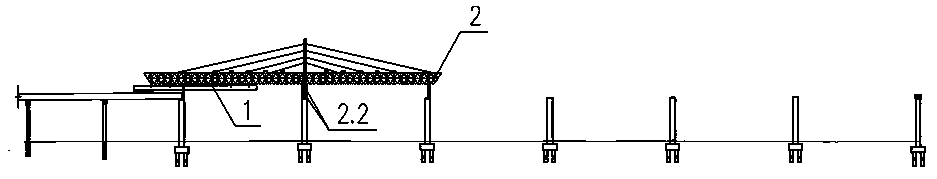

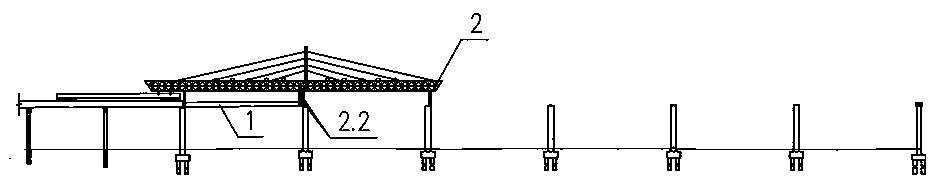

[0036] The construction method of the two-span steel-concrete composite bridge adopting the back-cable type bridge erecting machine of the present invention is suitable for the situation that the steel girder unit span is 70-150m. Taking the steel-concrete continuous composite bridge with six spans and one connection as an example below, the construction method of the present invention will be described in more detail.

[0037] Such as Figure 1-7 Shown, the present invention mainly comprises the following steps:

[0038] In the first step, according to the bridge design scheme, prefabrication such as Figure 8 As shown in the steel beam unit 1, the steel beam unit 1 mainly includes a web 1.1 and a flange 1.2, and a temporary hanging piece 1.3 is welded on the flange 1.2.

[0039] In the second step, after the construction of the bridge foundation piles and bridge piers is completed, the bridge erecting machine 2 is put in place.

[0040] Such as Figure 9 As shown, the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com