Combined production steam synergistic device and method for coal water slurry gasification furnace and high-pressure boiler

A technology for high-pressure boilers and gasifiers is applied in the field of co-production steam efficiency enhancement devices of coal-water slurry gasifiers and high-pressure boilers, which can solve the problems of high utilization difficulty and low quality of saturated steam, and improve the utilization rate and steam quality. Improve and achieve the effect of safe and stable operation of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0025] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

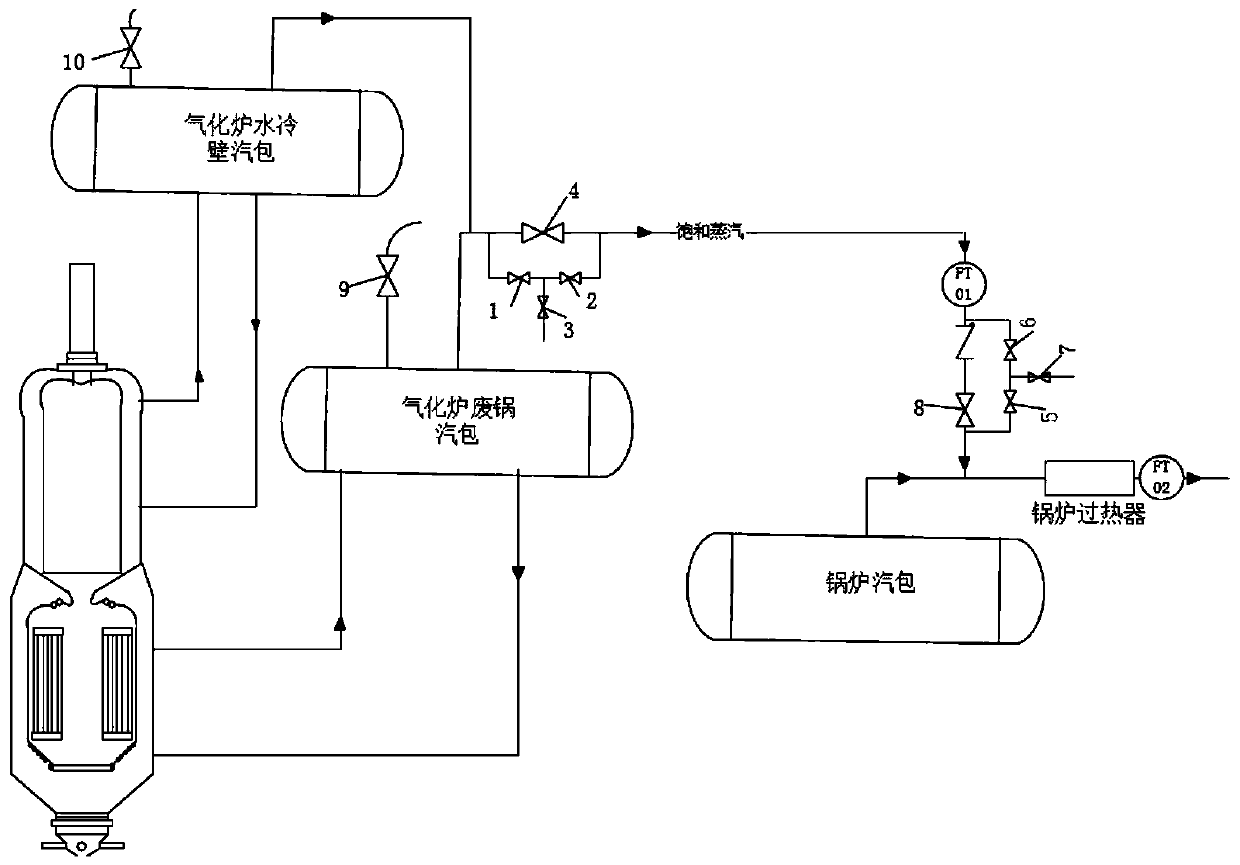

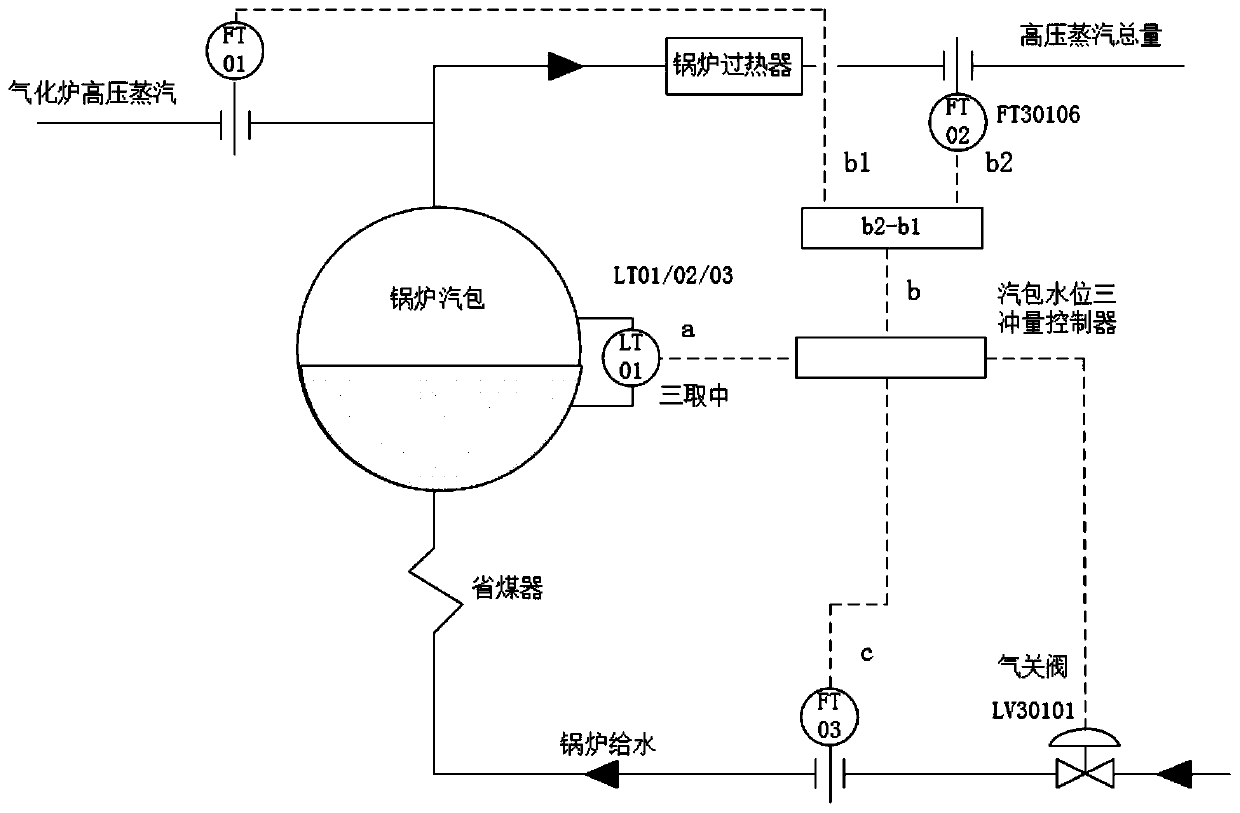

[0026] like figure 1 As shown, it is a schematic structural diagram of the coal-water slurry gasifier and the high-pressure boiler linkage synergistic device of the present invention, which is to pass the saturated steam outlet pipeline of the coal-water slurry gasifier and the drum steam outlet pipeline of the high-pressure fluidized bed boiler through a The steam delivery pipelines are connected, specifically, the steam outlet pipelines of the gasifier water wall drum of the coal-water slurry gasifier and the steam outlet pipeline of the waste boiler drum of the gasifier are connected with the steam outlet pipelines of the boiler drum. There are valve group A and valve group B on the steam transmission pipeline, and the setti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com