Fusion calibration method of three-dimensional laser radar and binocular visible light sensor

A three-dimensional laser, calibration method technology, applied in instruments, image data processing, radio wave measurement systems, etc., can solve problems such as complex calibration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

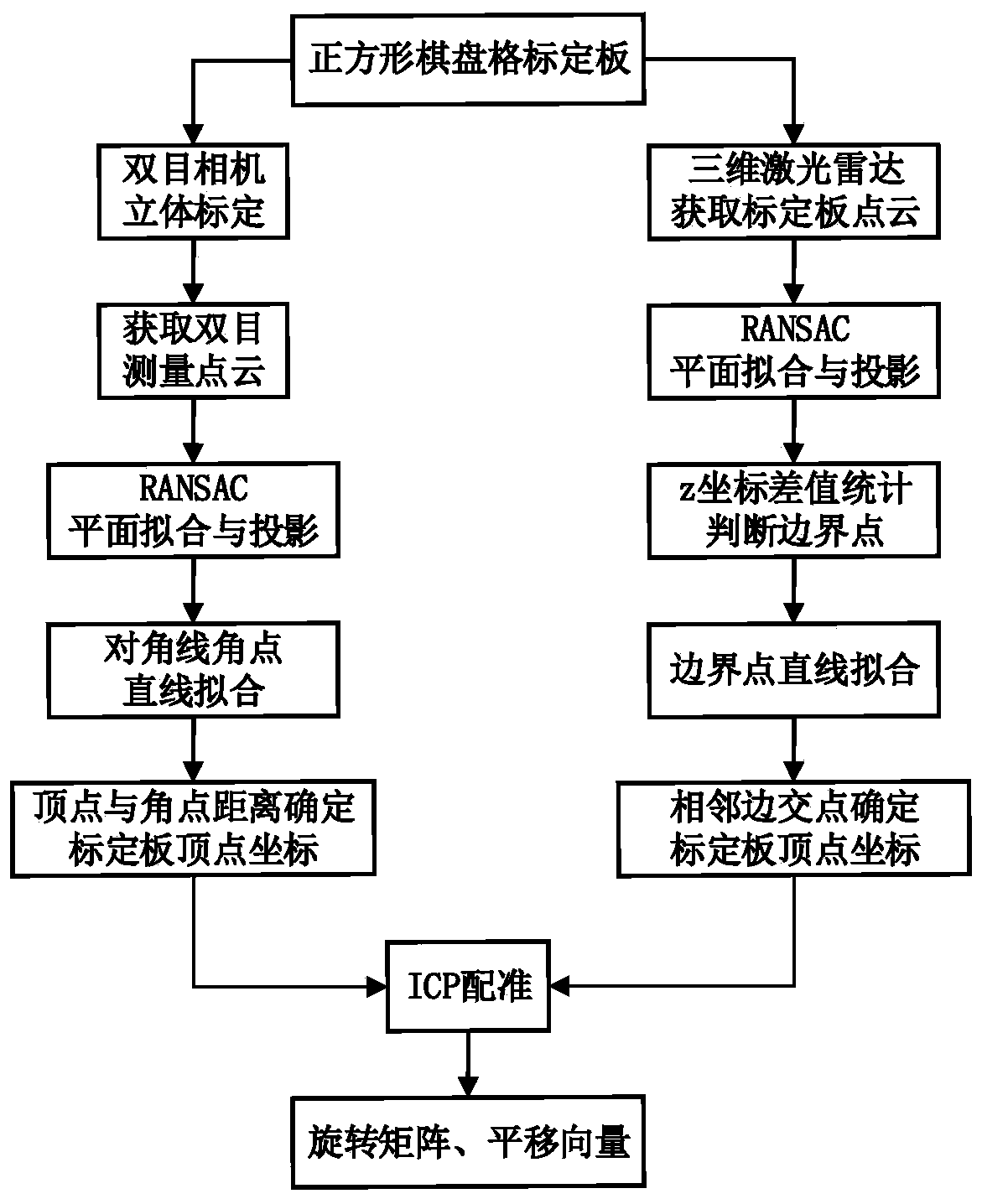

[0020] The system flow chart of the present invention is as figure 1 As shown, the specific implementation steps are as follows:

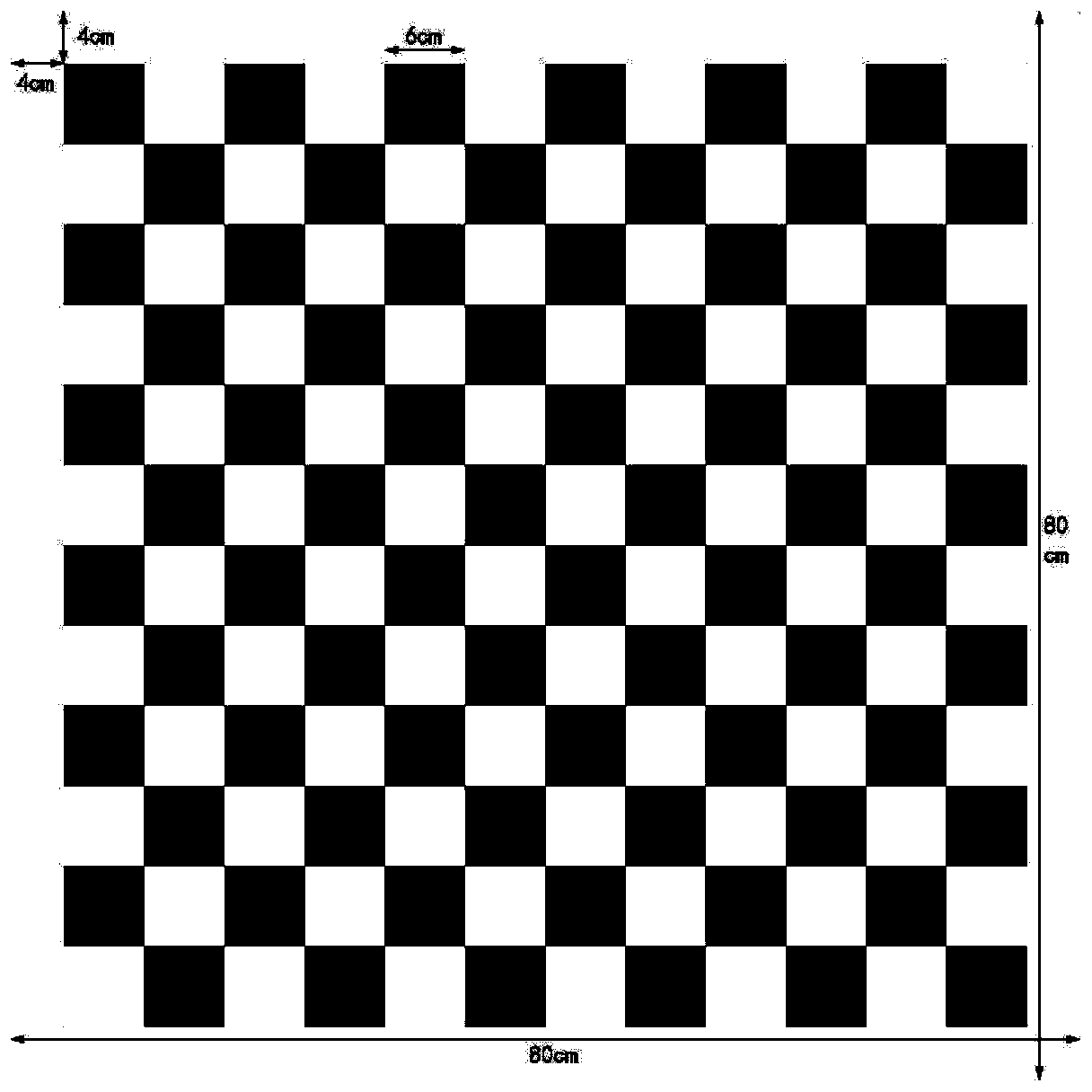

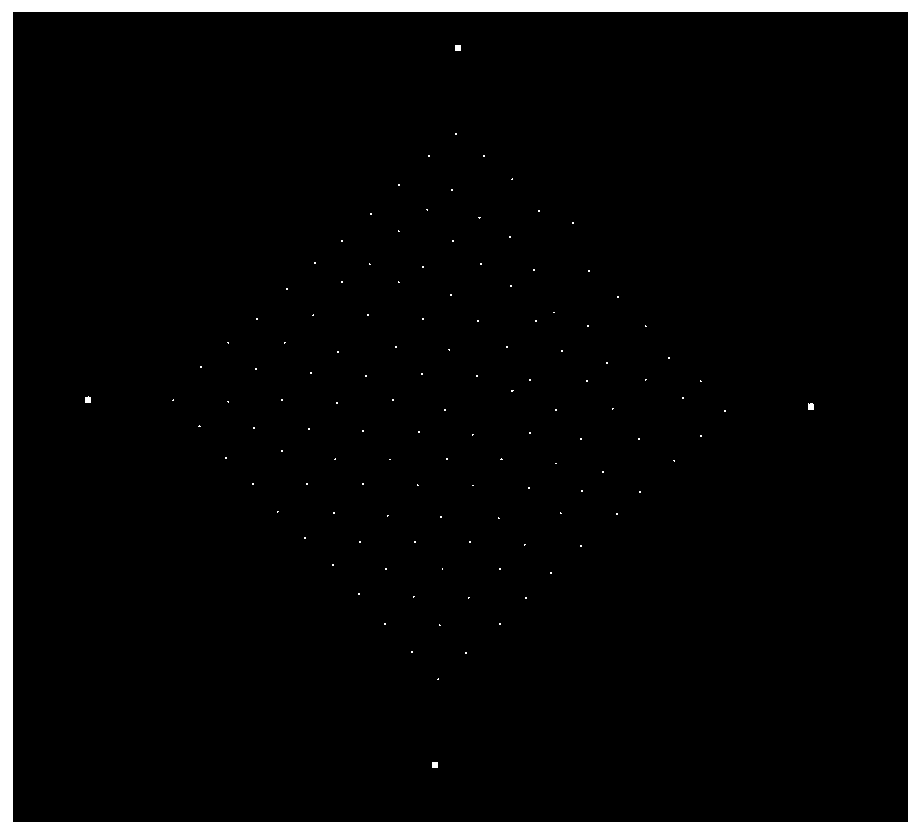

[0021] 1. Build a fusion calibration system, including 3D laser radar, binocular camera and checkerboard calibration board. The calibration board is an opaque acrylic board with a checkerboard pattern. The diagonal lines are vertical and parallel to the ground respectively, and the height of the calibration plate is adjusted so that all four sides intersect with the scanning line of the lidar.

[0022] 2. Stereo calibration of binocular cameras

[0023] First, perform monocular camera calibration on the left and right cameras respectively, use the checkerboard calibration board and Zhang Zhengyou calibration method, change the position and angle of the calibration board, collect multiple sets of data, obtain the internal parameter matrix, distortion coefficient of the left and right cameras, and each set of data The respective rotation matrices R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com