A kind of food processing equipment and processing method thereof

A technology of food processing and equipment, which is applied in the field of food processing equipment and its processing, can solve the problems affecting the mixing mode of the taste, and achieve the effects of reducing production costs and workers' workload, improving work efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

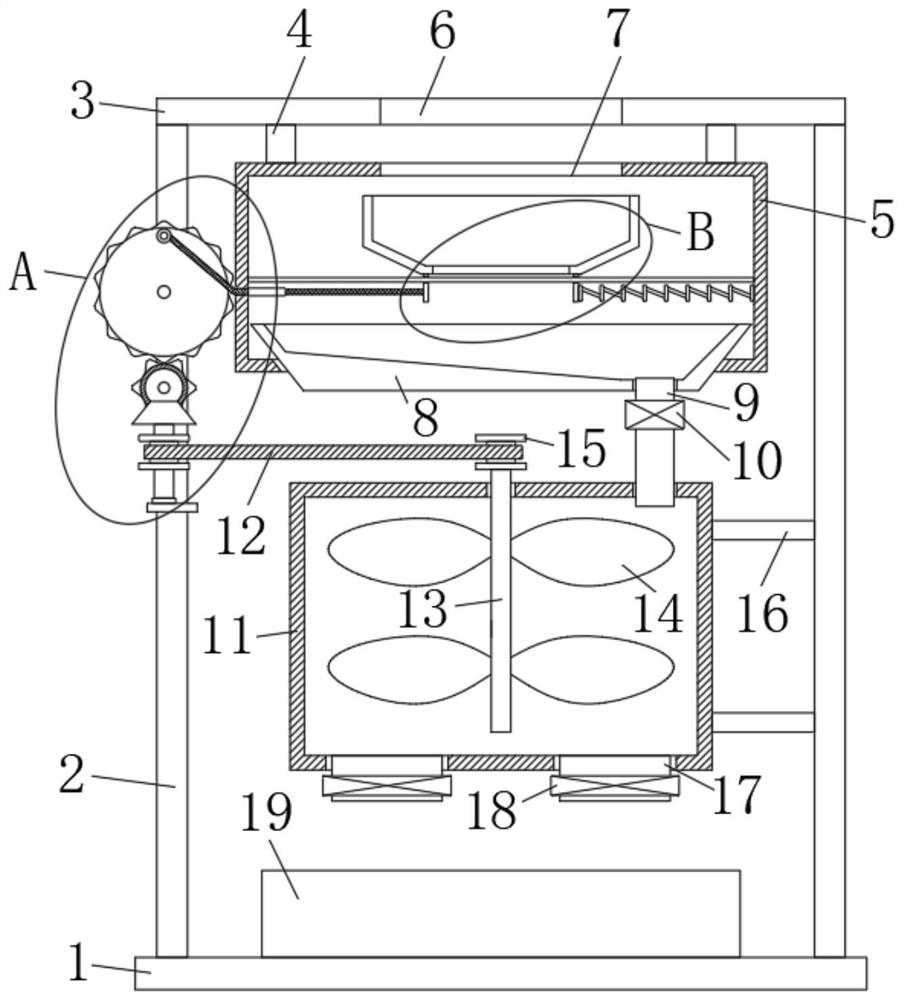

[0029] A food processing method, comprising the steps of:

[0030] S1, prepare the following raw materials in parts by weight: 100 parts of flour, 30 parts of corn flour, 20 parts of buckwheat flour, 5 parts of brown sugar powder, 10 parts of crushed peanuts, 20 parts of black bean flour, and 30 parts of sorghum flour;

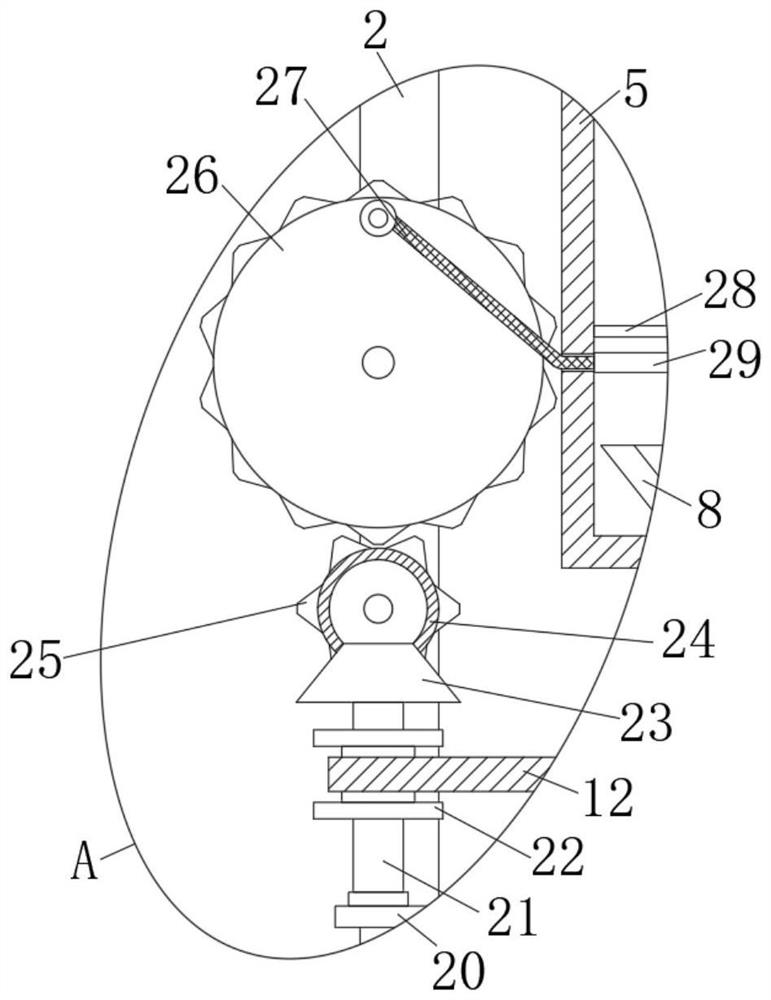

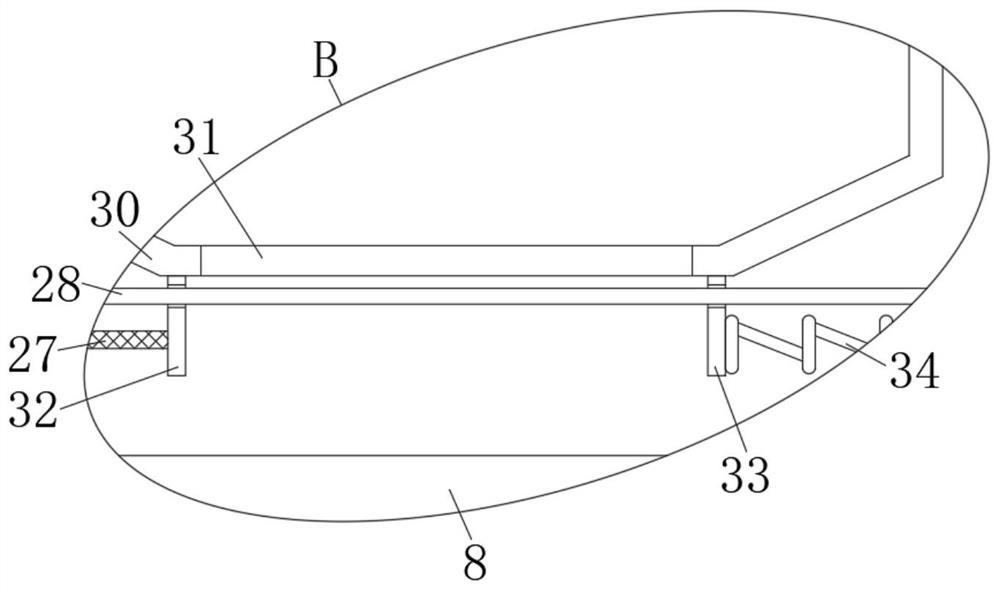

[0031] S2, put flour, corn flour, buckwheat flour, brown sugar powder, crushed peanuts, black bean flour, and sorghum flour into the screening basin 30 through the first feeding port 6 and the second feeding port 7 in sequence, start the motor, 26. Under the combined action of the pull rope 27 and the spring 34, the reciprocating movement of the screening basin 30 is realized, and then the screening of flour, corn flour, buckwheat flour, brown sugar powder, ground peanuts, black bean flour, and sorghum flour is realized, so that it can pass through Screening net 31 drops on material guide plate 8;

[0032] S3, open the first valve 10, so that the flour after ...

Embodiment 2

[0036] A food processing method, comprising the steps of:

[0037] S1, prepare the following raw materials in parts by weight: 150 parts of flour, 50 parts of corn flour, 40 parts of buckwheat flour, 8 parts of brown sugar powder, 13 parts of crushed peanuts, 25 parts of black bean flour, and 40 parts of sorghum flour;

[0038] S2, put flour, corn flour, buckwheat flour, brown sugar powder, crushed peanuts, black bean flour, and sorghum flour into the screening basin 30 through the first feeding port 6 and the second feeding port 7 in sequence, start the motor, 26. Under the combined action of the pull rope 27 and the spring 34, the reciprocating movement of the screening basin 30 is realized, and then the screening of flour, corn flour, buckwheat flour, brown sugar powder, ground peanuts, black bean flour, and sorghum flour is realized, so that it can pass through Screening net 31 drops on material guide plate 8;

[0039] S3, open the first valve 10, so that the flour after ...

Embodiment 3

[0043] A food processing method, comprising the steps of:

[0044] S1, prepare the following raw materials in parts by weight: 200 parts of flour, 60 parts of corn flour, 50 parts of buckwheat flour, 10 parts of brown sugar powder, 15 parts of crushed peanuts, 30 parts of black bean flour, and 50 parts of sorghum flour;

[0045] S2, put flour, corn flour, buckwheat flour, brown sugar powder, crushed peanuts, black bean flour, and sorghum flour into the screening basin 30 through the first feeding port 6 and the second feeding port 7 in sequence, start the motor, 26. Under the combined action of the pull rope 27 and the spring 34, the reciprocating movement of the screening basin 30 is realized, and then the screening of flour, corn flour, buckwheat flour, brown sugar powder, ground peanuts, black bean flour, and sorghum flour is realized, so that it can pass through Screening net 31 drops on material guide plate 8;

[0046] S3, open the first valve 10, so that the flour after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com