Squeegee cleaning device and application method of powder spreading type 3D printer

A 3D printer and scraper technology, applied in the field of 3D printing, can solve the problems of unqualified parts, powder falling from the scraper to the forming platform, and powder that is easy to stick and dye, etc., and achieve the effects of simple structure, improved product quality, and reduced scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

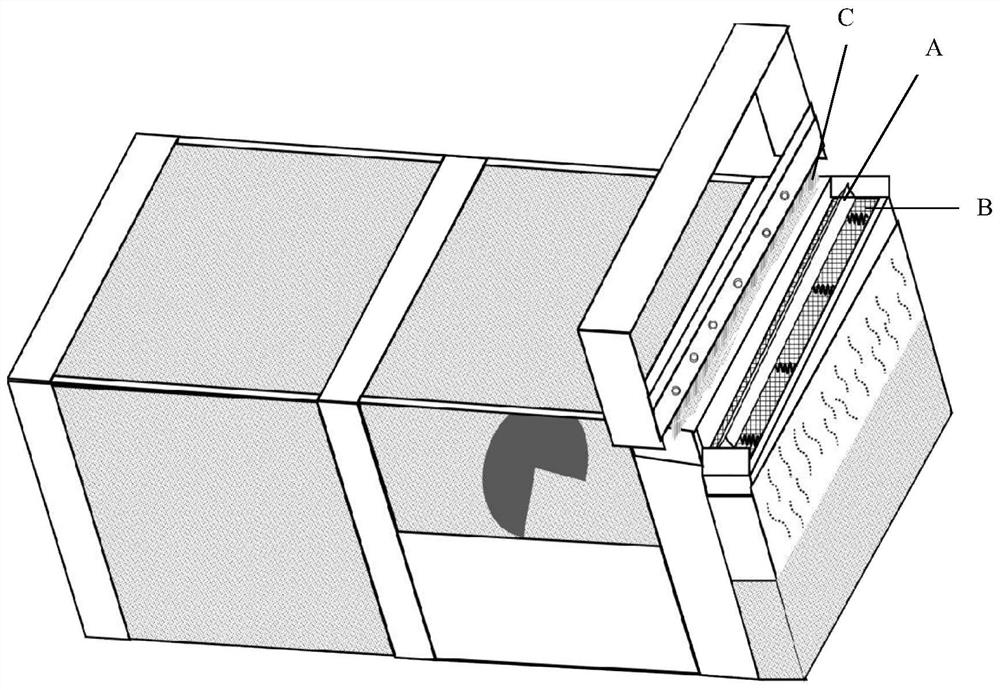

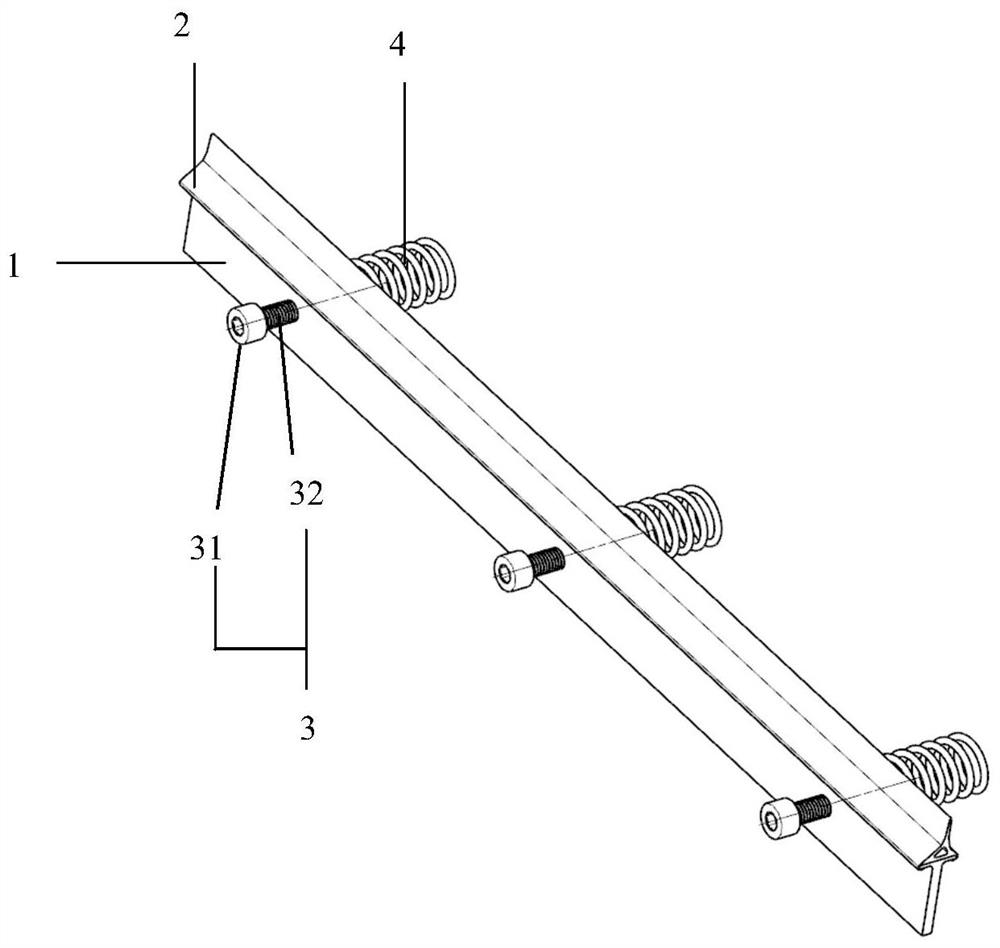

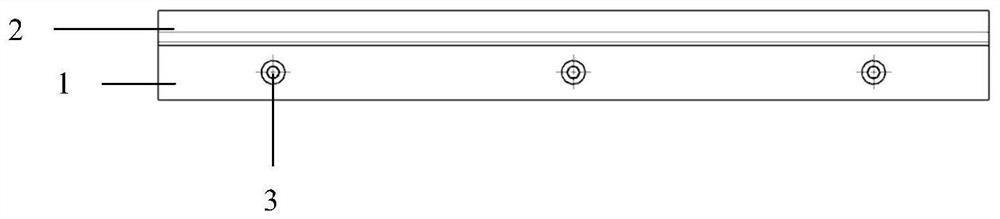

[0028] figure 1 It is the schematic diagram of the 3D printer of the first embodiment of the present invention. figure 2 , image 3 , Figure 4 It is a schematic diagram of the first embodiment of the 3D printer scraper cleaning device of the present invention. in, figure 2 It is a three-dimensional view of the 3D printer scraper cleaning device according to the first embodiment of the present invention, image 3 It is the front view of the 3D printer scraper cleaning device of the first embodiment of the present invention, Figure 4 It is a top view of the 3D printer blade cleaning device according to the first embodiment of the present invention.

[0029] Such as figure 1 As shown, the 3D printer blade powder cleaning device A disclosed in this embodiment is installed adjacent to the powder drop tank B. The 3D printer scraper C is cleaned of powder, and the powder drop tank collects the cleaned powder.

[0030] Such as figure 2 , image 3 and Figure 4 As shown...

no. 2 example

[0039] Figure 5 It is the schematic diagram of the 3D printer of the second embodiment of the present invention. Figure 6 It is a perspective view of a 3D printer scraper cleaning device according to the second embodiment of the present invention.

[0040] Such as Figure 5 As shown, the 3D printer scraper powder cleaning device A disclosed in this embodiment is installed adjacent to the powder drop tank B to clean the 3D printer scraper C, and the powder drop tank collects the removed powder.

[0041] Such as Figure 6 As shown, the 3D printer blade cleaning device disclosed in this embodiment includes a support frame 1 , a brush 5 , a screw 3 and a spring 4 . In this embodiment, the soft material is a brush, and the elastic device is a spring.

[0042] Such as Figure 6 As shown, the cross section of the support frame 1 is T-shaped, and is set on the printing platform of the 3D printer. The bottom of the support frame 1 is in contact with the 3D printer platform, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com