Argon filling protection device for welding back surface of stainless steel or dissimilar steel branch pipe

A branch pipe welding and protection device technology, applied in the direction of supply/removal of protective gas, welding equipment, welding accessories, etc., can solve the problems of argon waste, uneconomical, high cost, convenient on-site disassembly and assembly, and engineering use effect. Excellent, low manufacturing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

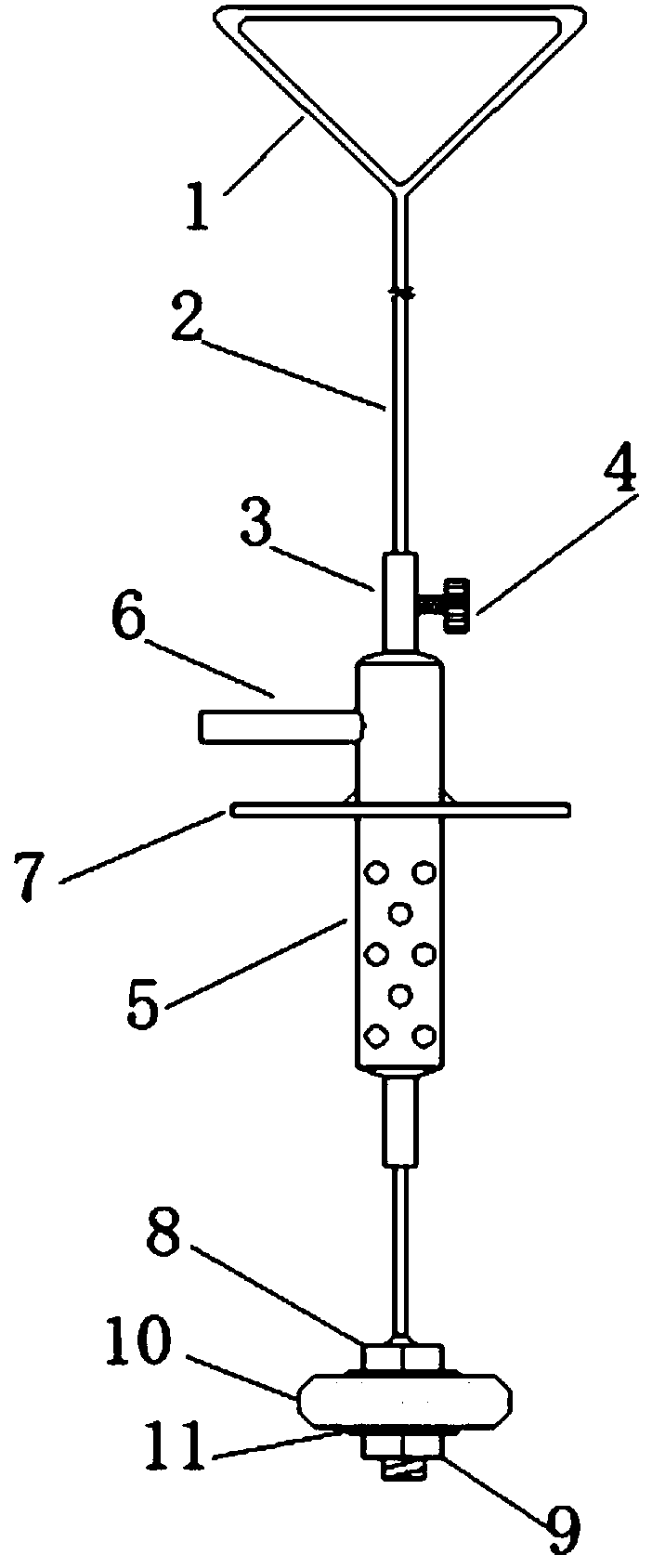

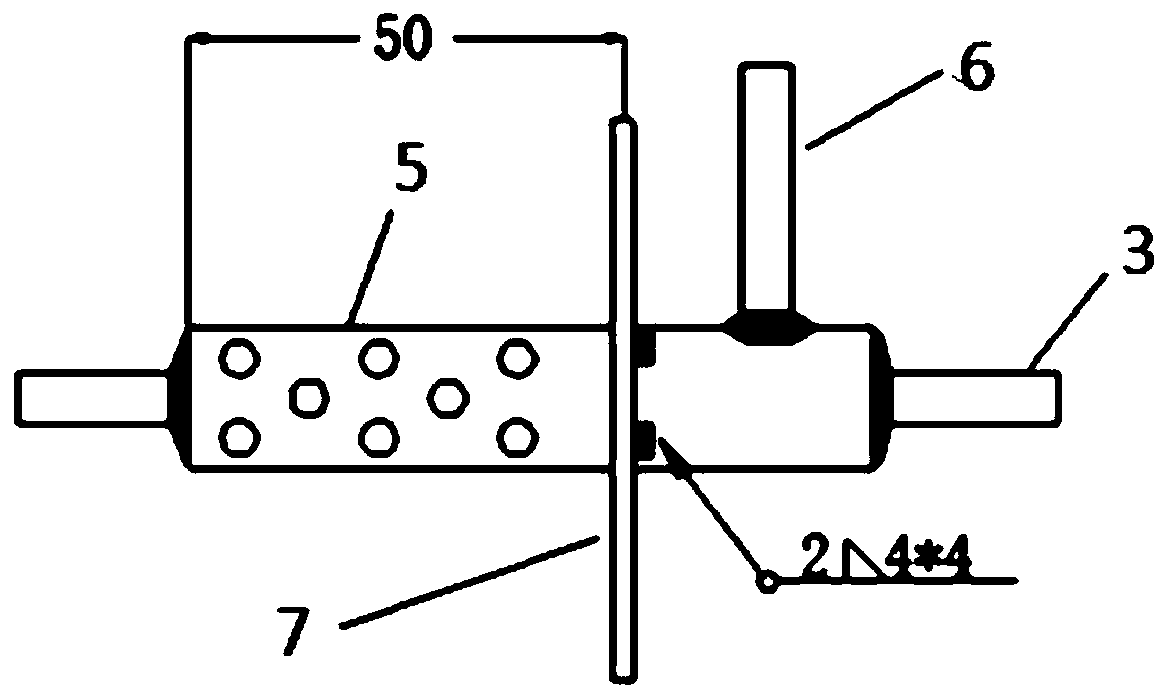

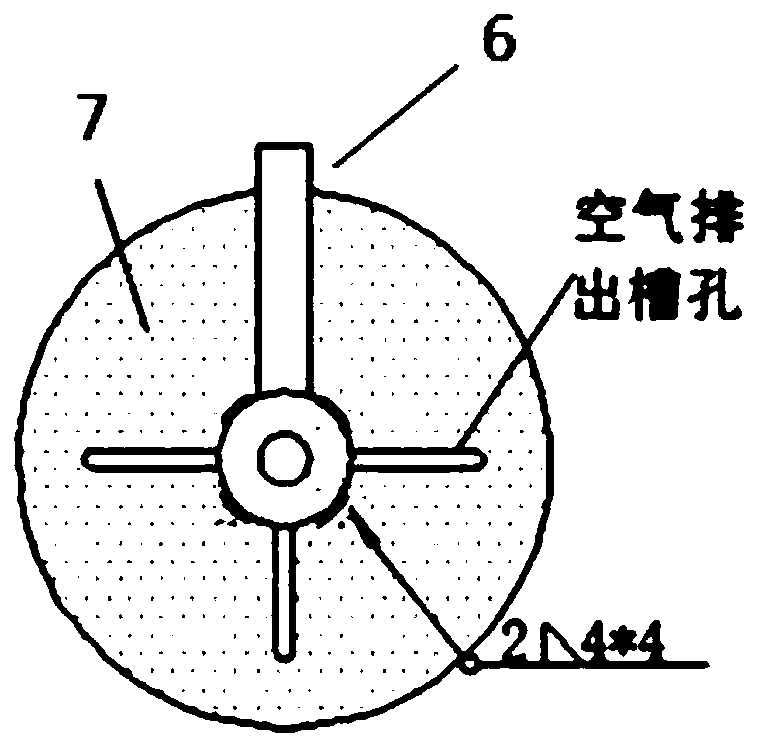

[0043] Such as figure 1 As shown in -5, the argon-filled protection device on the back of stainless steel or dissimilar steel branch pipe welding of the present invention includes: handle 1, slide bar 2, round pipe slide rail 3, fastening screw 4, gas distribution pipe 5, argon gas inlet pipe 6 , Circular cover plate 7, bolt 8, nut 9, rubber piston pad 10 and gasket 11.

[0044] The slide bar 2 adopts Φ1.6mm stainless steel welding wire, its upper end is welded to the handle 1, the lower part of the slide bar 2 passes through the round tube slide rail 3, and the round tube slide rail 3 has a threaded hole at the end of the handle 1, and is threadedly connected with the fastening screw 4. The two ends of the round pipe slide rail 3 and the gas distribution pipe 5 are connected by sealing welding, the gas distribution pipe 5 passes through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com