Feedback active cooling high temperature fiber tip timing sensor

A technology of active cooling and blade tip timing, which is applied in the direction of instruments, household refrigeration devices, lighting and heating equipment, etc., can solve the problem that the optical fiber sensor cannot withstand such a high level, and achieve the effect of avoiding overheating, preventing damage, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

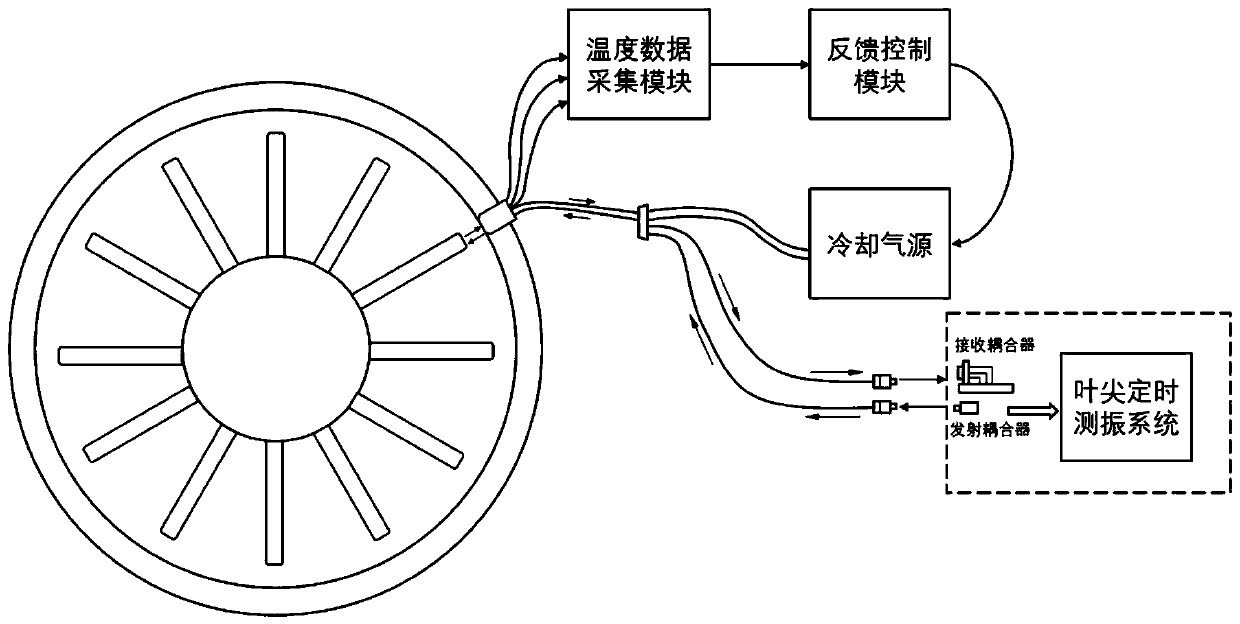

[0021] Such as Figure 1 to Figure 5 As shown, the present invention provides a feedback type active cooling high temperature optical fiber tip timing sensor, which includes a sensor probe, a temperature data acquisition module, a feedback control module and a cooling air source.

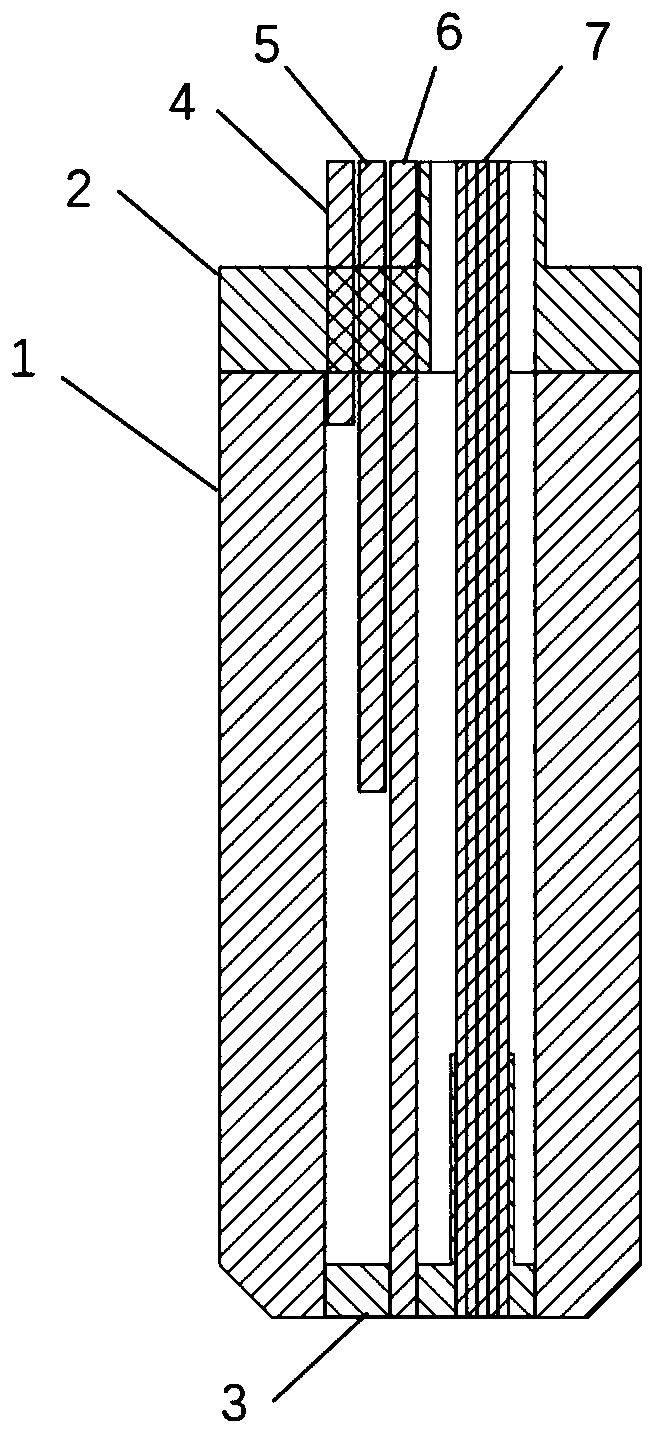

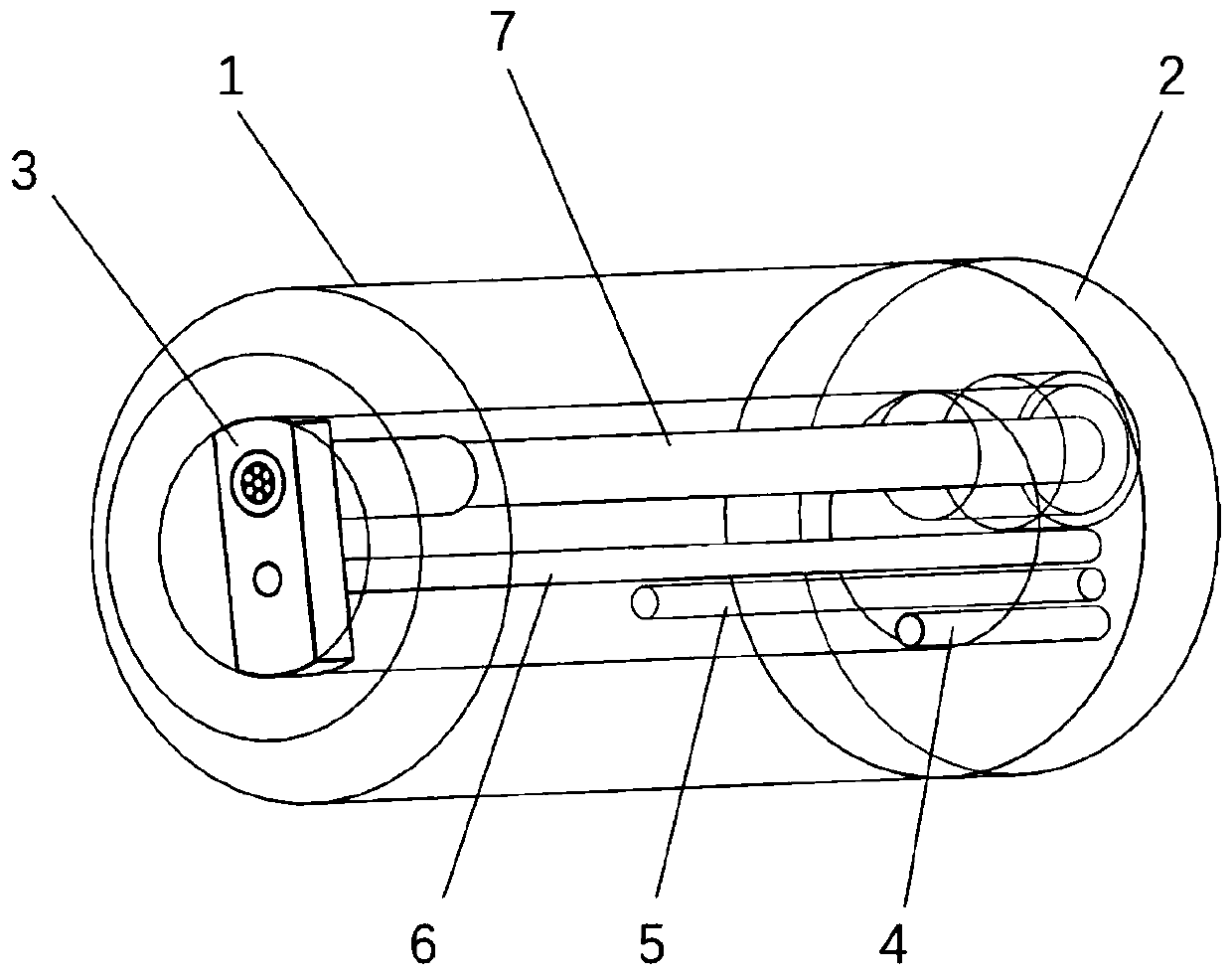

[0022] The sensor probe is mainly composed of a probe housing 1, a sealed air intake cover 2, an optical fiber fixing member 3, a tail thermocouple 4, a middle thermocouple 5, a head thermocouple 6, and an optical fiber bundle 7 with a transmitting fiber and a receiving fiber inside. The main function of the probe housing 1 is to protect the internal components of the sensor probe. Its main body is a hollow cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com