An intelligent brick device for monitoring the damage degree of a monolithic wall and its monitoring method

A technology of damage degree and monolithic wall, which is applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve the problems of unconcealed engineering inspections, time-consuming and laborious on-site inspection conditions, etc. problems, to achieve a broad promotion market and application prospects, to reduce the influence of line break factors, and to make the production and installation process simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

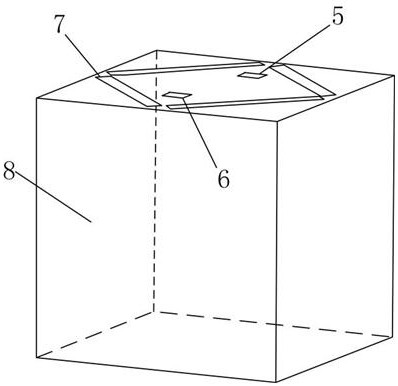

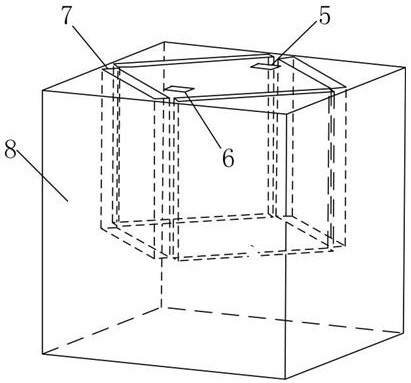

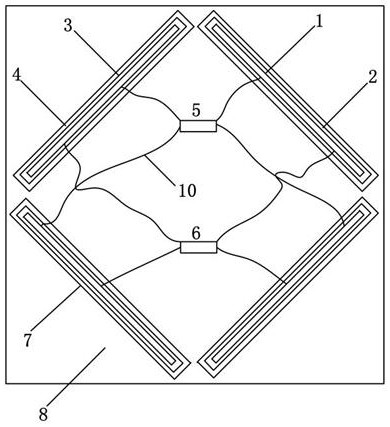

[0030] Such as Figure 1~8 As shown, a smart brick device for monitoring the damage degree of a single wall, including five smart bricks A, B, C, D, E;

[0031] Four square piezoelectric ceramic sheets 1 are respectively embedded in the smart brick A at an angle of 45° with the brick edge, and the piezoelectric ceramic sheets 1 are arranged in the vertical direction; The negative wires are respectively connected to the positive wire pinhole 5 and the negative wire pinhole 6; smart brick A can transmit stress wave signals to four directions at the same time; smart brick B, smart brick C, smart brick D and smart brick E are connected to bricks A piezoelectric ceramic sheet 1 is embedded at an angle of 45° between the side lines to receive signals; when the masonry structure is damaged, the propagation path of the stress wave signal emitted by smart brick A will change, compared with smart brick B and smart brick C , Smart Brick D and Smart Brick E receive the form of the stress...

specific Embodiment approach

[0040] The specific implementation is as follows: using mechanical mixing clay and steel fibers, put them into a mold with grooves, then, dry the bricks at 90°C for 6 hours and burn them at 900°C for 6 hours. There are several grooves of the same size on the square bricks mixed with steel fibers, and the number of grooves is determined according to the number of piezoelectric ceramic sheets to be embedded; after the square bricks are successfully manufactured, install positive and negative wires on the surface of the brick Pinhole, the position of the pinhole can be determined according to the position of the groove; square piezoelectric ceramic sheets with positive and negative wires are respectively embedded in the groove mouth, and the square piezoelectric ceramic sheets embedded in the groove need to be pretreated as follows: select a size smaller than The grooved square piezoelectric ceramic sheet is welded with positive and negative lead wires on the surface of the square...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com